RMG Crane- Rail mounted gantry crane, Your Container Crane, Good priced

RMG crane is a rail mounted gantry crane for ISO standard container handling. Wide specifications of rail mounted gantry cranes meet your container crane requirements. Get RMG crane price now!

| Crane Type | Rail mounted gantry crane, container crane |

| Crane Capacity | 30 ton -50 ton |

| Crane Span | 18-35m |

| Lifting Height | 12.3-21m |

| Working Class | A6-A8 |

Category: Gantry Crane

Your Trusted Gantry Crane Manufacturer & Supplier

30 Ton- 50 Ton Rail Mounted Gantry Cranes

Heavy Duty Gantry Cranes

Rail Mounted Gantry Crane, shorten as RMG crane is a type of container cranes for lifting the international ISO standard containers. Adopting U frame supporting legs , the rail mounted gantry crane has wider clear space than the regular gantry crane, which enables containers move to sides easily. The whole RMG crane is designed to run quickly and steadily on the fixed gantry rails on ground for efficient container handling in outdoor workplaces, such as, port and dock, etc. With high operating speed and working level, the rail mounted gantry cranes is aimed to offer you the efficient container handling solution and to boost your business productivity.

Rail mounted gantry crane with container spreader - Container Cranes

Rubber tyred gantry crane with hook for stone block handling- stone handling crane

RMG crane with Hook vs RMG crane with spreader

As rail mounted gantry crane manufacturers, we are devoted to provide cost-effective and efficient material handling solution. Through years study and development, two main types of Rail mounted gantry cranes are presented for various material handling.

- Regular Rail mounted gantry cranes for general material handling - The rail mounted gantry crane with hook is for general material handling in stock , yard, and stack and when it is hook with sling, the RMG crane will also can be used for containers handling, which is a cost-effective solution in therm of equipment budget cost and crane applications.

- Specialized Rail mounted gantry crane for container handling - The RMG crane is designed for container handling with specialized container handling spreader, only used for lifting containers, and the lifting capacity under spreader up to 50 ton.

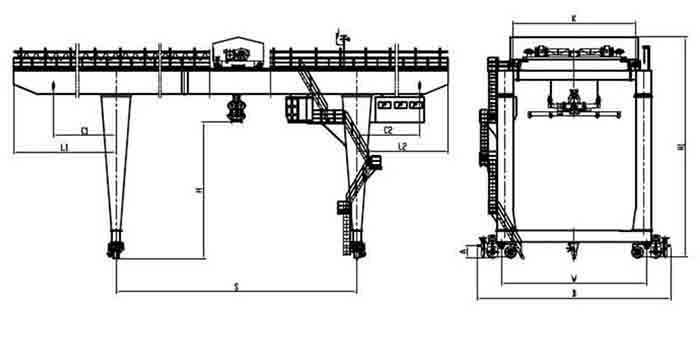

Parameters of rail mounted gantry crane

The main parameters and specifications of the Rail mounted gantry cranes are presented for your reference. And If your container crane requirements needs custom design, please feel free to contact us.

Rail mounted gantry crane parameters:

- Load capacity of Rail mounted Gantry : 30 ton -50 ton

- Span of Rail mounted Gantry : 18-35m

- Lifting height of Rail mounted Gantry : 12.3-21m

- Lifting speed of Rail mounted Gantry : 9.2-12.5m/min

- Trolley running speed of Rail mounted Gantry : 45-56m/min

- Crane running speed of Rail mounted Gantry : 42-50m/min

- Work duty of Rail mounted Gantry : A6-A8

- Power supply of RMG crane : 3P 50HZ, 380V

- Application temperature of RMG crane : -25~+40 centigrade

- Relative humidity of working environment : No more than 50% when the temperature is +40 centigrade

Rail mounted gantry crane specifications

- Lifting height vs. Lifting speed -The hoisting height of rail mounted crane is determined by the requirements of container handling yard, according to "heap three over four" or "heap four over five". and due to the lifting height is not so high, and correspondingly the hoisting speed of containers is relatively slow.

- Crane travelling length vs crane travelling speed-The travelling length of the container gantry crane is generally long running along in the direction of crane track in container yard. To improve the productivity, , the rail mounted gantry crane is able to achieve a higher travelling speed.

- Crane Span and cantilever length vs Hoisting trolley speed -The hoisting trolley running speed of the rail gantry crane can be determined according to the length of crane span and the extended cantilevers. The shorter the length of crane span and cantilever is, the slower the running speed of crane trolley will be and the longer the length is, the higher the speed will be.

40.5 ton rail mounted gantry crane for container handling

Structure & Components

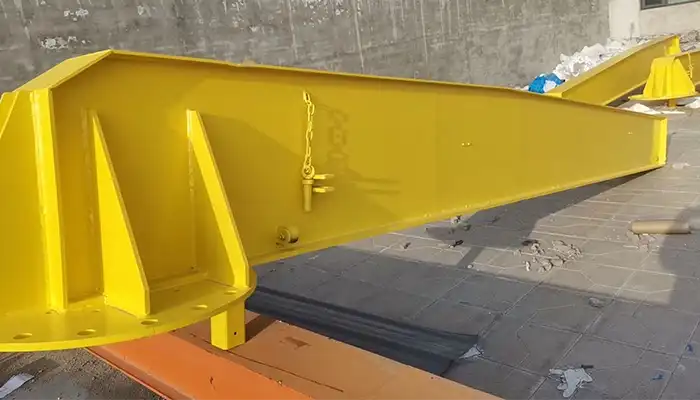

The main structure of the rail mounted gantry crane is a cantilever double girder gantry crane, supported on U frame legs, running on the fixed crane rail on ground.

The main crane parts and components of the RMG cranes are including gantry frame, eclectic hoisting mechanism, trolley traveling mechanism, gantry crane traveling mechanism, and supply system, i.e. cable reel, trolley power supply system and other components,etc. And also the RMG crane are equipped with the accessories such as anchoring device, wind cable device, lightning protection device, anemometers and other, etc.

The main structures and crane parts of the rail mounted gantry crane are presented in the above picture for your reference. Please contact us to get detailed customized CAD RMG crane drawing.

Application

Rail mounted gantry crane is your optimal container crane solution and general material handling crane solution.

The rail mounted gantry cranes is a special container crane, designed for loading and unloading the international ISO standard containers in terminal, container yard , cargo yards, port, outside stores railway freight station, etc. The rail mounted gantry crane with hook is not only for container handling but also can be used for general material handling in stock , yard, and stack, etc.

The rail mounted gantry crane is a good choice when a cost-effective lifting solution is need for container handling and general material handling.

Rail mounted gantry crane vs. Rubber-tired gantry crane

Rail mounted gantry crane and rubber tired gantry cranes are two types of specialized gantry cranes used for container loading and unloading. Both of the rmg crane and rtg cranes are widely used in yards and ports and other applications. What is the difference between the two types of container cranes? Let's compare the two container gantry cranes in term of travelling, lifting capacity and adaptability briefly for your reference.

Rail mounted gantry crane for container handling

Rail mounted gantry crane with U leg gantry design

Rail mounted gantry crane for container handling with capacity of 40.5 ton

Rail mounted gantry crane for container handling

- RMG rail mounted gantry crane runs on and along the gantry rails fixed on ground, with the working area of rmg crane limited by the coverage of the gantry rail. The RMG crane is powered by electricity.

- RTG rubber tired gantry crane is running on rubber tires, which enable the rtg crane able to move in 9 directions with more flexibility in lifting and transport. The RTG crane is powered by diesel engine, electricity power, or combination drive.

Lifting Capacity

- RMG crane are used for handling both containers and other long and large piece loads with , lifting capacity up to 600 ton.

- RTG crane are mainly used for containers handling, with the average lifting capacity of 35 ton, 40 ton and 45 ton.

Adaptability

- Both RMG crane and RTG crane are mainly used for lifting containers in freight yard and stock yard.

- RMG crane are used for handling both containers and other long and large piece loads but the working space are limited;

RTG crane is specially designed container crane, which are mainly used for busy container yard where container loading crane is required with high working efficiency.

Advantages of Rail Mounted Gantry Crane

For heavy loads handling, the rail mounted gantry crane is designed to reduce heavy loads lifting and transferring times and promote efficiency. The RMG crane is widely used in many industrial application with the following advantages:

- With strong adaptability, the rail gantry crane is suitable for many different working site conditions.

- The RMG crane has a long service life and a low maintenance requirement.

- The performance of rail mounted gantry crane is outstanding, with smooth and stable movement, and no swing during operation.

- Accurate positioning and minimal positioning time makes your rail gantry crane handling safe and efficient.

- The energy consumption of rmg crane is low which reduces the operation cost largely.

Customized 41 Ton RMG container gantry cranes project

In the following, it is one of our typical rail mounted gantry crane with container speader for an autombile company in Uzibekistan. Rail mounted gantry crane for sale Uzbekistan for container handling, capacity 41 ton, 4+1 containers. Check rmg container gantry crane specifications now.

- Types of Cranes: Rail Mounted Container Gantry Crane

- Date of Placing Order: 2021-06-24

- Date of delivery : 2021.12.22

- Transportation :Railway

- Payment: 30% TT prepaid, 35% TT completed main steel structure production, 30% TT before delivery, 5% TT installation completed

- Destination port: CIP Pitnak

- Destination country:Uzbekistan

- First contact:2015-3-21

- Click to check production of 41 ton double girder rail mounted gantry crane, please feel free to contact us to learn more or get your customized rmg crane design for free. WhatsApp: + 86 151 3871 1597.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch