Gantry Cranes Russia. Indoor & Outdoor Gantry Crane & Goliath Crane

Gantry crane for sale Russia. Indoor & gantry cranes with single/ double girder, full gantry & semi gantry design for various industrial use 1 ton to 320 ton.

Category: Russia

Your Trusted Gantry Crane Crane Manufacturer & Supplier

Gantry Cranes Russia. Indoor & Outdoor Gantry Crane & Goliath Crane

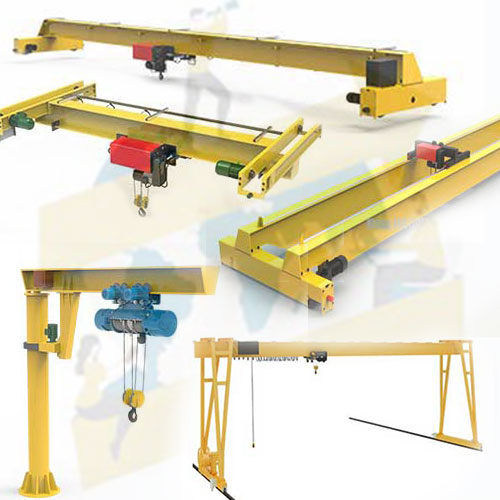

Indoor & Gantry Cranes with Single/ Double Girder, Full Gantry & Semi Gantry Design For Sale

Gantry crane for sale Russia. Indoor & gantry cranes with single/ double girder, full gantry & semi gantry design for various industrial use 1 ton to 320 ton.

Elevating Industries: Understanding the Basics of Gantry Cranes in Russia

In the vast expanse of Russia's industrial tapestry, the towering figures of gantry cranes emerge as silent heroes, orchestrating the symphony of efficient material handling. This guide unravels the nuanced world of gantry cranes, providing a deep understanding of their types, applications, and the pivotal role they play in shaping Russia's industrial landscape.

Significance in Russian Industries

The Backbone of Efficiency: Gantry Cranes and Their Impact on Russia's Industrial Landscape

Gantry cranes are not just machines; they are the sinews that bind together the diverse sectors of Russia's industries. As we embark on this exploration, we uncover the profound impact gantry cranes wield, elevating operational efficiency and serving as the very backbone of Russia's industrial might. Their contribution resonates through ports, manufacturing facilities, construction sites, and beyon

Types of Gantry Cranes in Russia

Rubber-Tired Gantry Cranes (RTG)

A frame rubber tyred gantry crane for sale

U frame rubber tyred gantry crane for sale

Mobility Unleashed: Exploring Rubber-Tired Gantry Cranes for Sale in Russia

In the dynamic landscape of Russia's industrial hubs, Rubber-Tired Gantry Cranes (RTG) emerge as the epitome of mobility and efficiency. These cranes, equipped with rubber tires, redefine the handling of cargo in container yards and logistics hubs across the nation.

Crane Design & Capacities:

RTG cranes, with their innovative design, offer a perfect blend of flexibility and lifting capacity. Ranging from 10 to 100 tons, these cranes are tailored to meet the diverse needs of Russia's bustling logistics and container management.

Tailored Features for Operation in Russia:

Adapting to Russia's unique operational challenges, RTG cranes come with advanced features such as real-time tracking systems, automated container positioning, and robust weather-resistant designs. These features ensure seamless operations even in harsh weather conditions.

Applicable Industries:

RTG cranes find their application in container yards, ports, and intermodal terminals. Their ability to move swiftly and handle containers with precision makes them indispensable in industries relying on efficient cargo handling.

Typical Industrial Locations & Crane Project Locations:

Major port cities like St. Petersburg and Novorossiysk witness the significant deployment of RTG cranes. The efficiency and mobility of these cranes make them ideal for container yards and logistics centers across the expansive Russian landscape.

In the bustling ports and logistics centers of Russia, RTG cranes stand as a testament to innovation, enabling the swift and efficient handling of containers to meet the demands of the nation's growing trade and commerce.

Rail Mounted Gantry Cranes (RMG)

Rail mounted gantry crane for sale

U frame rail mounted gantry crane for sale

On Track for Success: Rail Mounted Gantry Cranes Tailored for Russia's Ports

In the intricate ballet of logistics within Russia's ports and terminals, Rail Mounted Gantry Cranes (RMG) take center stage, orchestrating the seamless flow of goods with precision. This segment delves into the efficiency and tailored features of RMG cranes that make them indispensable in Russia's vital maritime hubs.

Crane Design & Capacities:

RMG cranes are designed for precision and efficiency in container handling. With lifting capacities ranging from 50 to 150 tons, these cranes are the workhorses of Russia's ports, ensuring the swift and secure movement of containers.

Tailored Features for Operation in Russia:

Adapting to the demands of Russia's bustling ports, RMG cranes come equipped with advanced features such as automated container positioning, anti-sway technology, and efficient rail-mounted systems. These features enhance operational efficiency and contribute to the overall productivity of port activities.

Applicable Industries:

RMG cranes find their application in ports and container terminals, where the linear track system allows for efficient movement and precise placement of containers. The design of RMG cranes is tailored to meet the demands of high-volume container handling operations.

Typical Industrial Locations & Crane Project Locations:

Major port cities like Vladivostok and Murmansk witness the strategic deployment of RMG cranes, optimizing container handling operations and contributing to the smooth functioning of Russia's maritime trade.

As Russia continues to play a pivotal role in international trade, the efficiency and reliability of Rail Mounted Gantry Cranes are vital components in the nation's success story, ensuring that goods move seamlessly through its ports, connecting the nation to the global marketplace.

Single Girder Gantry Cranes

Single girder gantry crane for sale Russia

Truss girder single girder gantry crane for sale Russia

Precision in Every Lift: Single Girder Gantry Cranes Shaping Russia's Manufacturing Sector

Amidst the rhythmic hum of machinery and the pulse of manufacturing activities in Russia, Single Girder Gantry Cranes emerge as stalwart performers, embodying precision and adaptability in every lift. This segment unveils the vital role played by these cranes in shaping the landscape of Russia's manufacturing sector.

Crane Design & Capacities:

Single Girder Gantry Cranes are engineered for versatility, with lifting capacities ranging from 1 to 20 tons. Their streamlined design and efficient operation make them ideal for a wide array of material handling tasks within manufacturing facilities.

Tailored Features for Operation in Russia:

Adaptability is the key, and Single Girder Gantry Cranes showcase this trait seamlessly. Tailored features include compact designs, easy maneuverability, and precise load control, making them invaluable assets in the dynamic and varied environments of manufacturing settings in Russi

Applicable Industries:

These cranes find their application in manufacturing units, workshops, and warehouses. Their ability to navigate tight spaces and handle loads with precision positions them as indispensable tools in the manufacturing processes of various industries.

Typical Industrial Locations & Crane Project Locations:

From the sprawling manufacturing plants in Moscow to the industrial zones in Yekaterinburg, Single Girder Gantry Cranes are deployed strategically. Their precision and adaptability contribute to the efficient material handling that is crucial for the success of Russia's manufacturing sector.

In the heart of manufacturing excellence, Single Girder Gantry Cranes stand tall, lifting the nation's industries to new heights of efficiency and productivity. Their precision in every lift echoes the commitment of the manufacturing sector in Russia to deliver quality products to the world.

Heavy Duty Excellence: Double Girder Gantry Cranes Meeting the Needs of Russia's Heavy Industries

In the crucible of Russia's heavy industries, where strength and reliability are paramount, Double Girder Gantry Cranes emerge as titans, seamlessly meeting the demands of handling hefty loads. This section peels back the layers to reveal the robust excellence that defines these cranes and their indispensable role in Russia's steel, metallurgy, and heavy industries.

Crane Design & Capacities:

Double Girder Gantry Cranes are engineered for heavy-duty lifting, boasting capacities ranging from 5 to 500 tons. Their dual-girder configuration provides unparalleled stability and strength, making them the preferred choice for handling massive loads in Russia's heavy industries.

Tailored Features for Operation in Russia:

Adaptability takes center stage as these cranes are equipped with features like advanced control systems, precise load positioning, and durability against harsh operational conditions. These features ensure that Double Girder Gantry Cranes perform with excellence in the challenging environments of heavy industries.

Applicable Industries:

The applications of Double Girder Gantry Cranes extend to steel plants, metallurgical facilities, and other heavy industries where the handling of large and heavy materials is a daily requirement. Their strength and reliability make them indispensable assets in ensuring seamless operations.

Typical Industrial Locations & Crane Project Locations:

From the steel mills in Magnitogorsk to the metallurgical plants in Chelyabinsk, Double Girder Gantry Cranes stand tall, meeting the needs of Russia's heavy industries. Their presence is felt in the very heart of industrial production, contributing to the nation's prowess in heavy-duty manufacturing.

In heavy-duty industries where reliability is non-negotiable, Double Girder Gantry Cranes rise to the occasion, showcasing excellence in handling massive loads and playing a crucial role in fortifying the foundation of Russia's heavy industrial landscape.

Goliath Cranes (Full and Semi Goliath)

Beyond Heights: Full and Semi Goliath Cranes Redefining Outdoor Handling in Russia

In the expansive outdoor landscapes of construction sites and storage yards across Russia, giants roam the terrain – Full and Semi Goliath Cranes. This segment delves into the awe-inspiring world of these colossal machines, reshaping the narrative of outdoor material handling in the nation.

Crane Design & Capacities:

Goliath Cranes, both Full and Semi, boast impressive lifting capacities ranging from 10 to 500 tons. Their towering structures and extended reach make them ideal for handling materials across vast outdoor spaces, providing unparalleled efficiency in construction and storage applications.

Tailored Features for Operation in Russia:

Adaptability takes on a new dimension with Full and Semi Goliath Cranes. These machines are equipped with features such as telescopic booms, precise load control systems, and weather-resistant designs. Such features make them robust performers in the diverse outdoor conditions encountered in Russi

Applicable Industries:

Goliath Cranes find their application in construction projects, storage yards, and outdoor material handling operations. Their ability to cover extensive areas and lift heavy loads makes them indispensable in scenarios where traditional cranes may face limitations.

Typical Industrial Locations & Crane Project Locations:

From the construction sites in Moscow to the storage yards in Novosibirsk, the presence of Full and Semi Goliath Cranes is marke Their towering structures redefine the skyline, symbolizing efficiency and power in outdoor material handling across Russi

In the realm of outdoor handling, where heights are scaled and distances covered, Full and Semi Goliath Cranes emerge as symbols of efficiency and power. They redefine the boundaries of what is possible, contributing to the evolution of outdoor material handling practices in Russia.

Semi Gantry Crane & Portal Cranes

Seamless Handling: Portal Cranes Enhancing Operations Across Russian Industries

In the intricate tapestry of Russian industries, where versatility is key, Portal Cranes stand as silent architects of seamless handling. This section unveils the adaptability and integration capabilities of Portal Cranes, enhancing operations across diverse industrial settings, from manufacturing to sprawling construction projects.

Crane Design & Capacities:

Portal Cranes are designed with versatility in mind, offering lifting capacities ranging from 5 to 50 tons. Their distinctive portal structure, spanning a wide area, makes them ideal for handling materials with precision in a variety of industrial contexts.

Tailored Features for Operation in Russia:

Adaptability is at the core of Portal Cranes, featuring attributes like flexible configurations, customizable spans, and advanced control systems. These features enable Portal Cranes to seamlessly integrate into different industrial settings, providing efficient material handling solutions.

Applicable Industries:

Portal Cranes find their application across a spectrum of industries, including manufacturing, construction, and warehouses. Their ability to cover a wide working area and handle materials with precision positions them as versatile tools in the arsenal of Russian industries.

Typical Industrial Locations & Crane Project Locations:

From the manufacturing plants in Kazan to the construction sites in Sochi, Portal Cranes gracefully weave into the operational fabri Their seamless integration and efficiency make them valuable assets, contributing to the success of diverse industrial projects across Russi

In the dynamic landscape of Russian industries, Portal Cranes emerge as silent facilitators of efficiency. Their seamless handling capabilities and adaptability make them indispensable in ensuring the smooth flow of materials across diverse industrial scenarios, symbolizing versatility in action.

Features and Benefits of Industrial Gantry Cranes in Russia

Cutting-Edge Design and Capacities

Innovation in Action: Design and Capacities of Gantry Cranes for Sale in Russia

Embark on a journey through innovation as we delve into the cutting-edge designs and diverse capacities of gantry cranes tailored for the specific needs of Russian industries. This segment highlights how these cranes, with their state-of-the-art designs, contribute to the evolution of material handling across various sectors.

Design Innovations:

Gantry cranes for sale in Russia showcase the latest advancements in design, including streamlined structures, advanced control systems, and enhanced safety features. Each element is meticulously crafted to maximize efficiency and adaptability in the ever-evolving industrial landscape.

Diverse Capacities:

From the nimble 10-ton cranes to the robust 100-ton giants, the capacities of gantry cranes cover a broad spectrum. This diversity ensures that there is a crane tailored for every lifting need, supporting operations across industries with precision and reliability.

Tailored Features for Operation in Russia

Adapting to Challenges: Tailored Features for Gantry Crane Operation in Russian Conditions

Uncover the secrets behind the seamless operation of gantry cranes in the diverse and challenging conditions of Russi This section explores the tailored features that enable these cranes to thrive, ensuring optimal performance in the face of varying climates, terrains, and operational demands.

Weather-Resistant Designs:

Russian conditions can be demanding, but gantry cranes are built to weather the storm. Discover how these cranes feature weather-resistant designs, ensuring uninterrupted operation even in the harshest climates, from icy winters to scorching summers.

Advanced Safety Measures:

Safety is paramount, and gantry cranes operating in Russia are equipped with advanced safety measures. From anti-sway technology to real-time monitoring systems, these features guarantee safe and secure material handling operations in every environment.

Gantry cranes in Russia are not just tools; they are embodiments of innovation and adaptability. Their cutting-edge designs and tailored features set the stage for elevated efficiency and performance, ensuring they seamlessly integrate into the diverse operational landscapes of Russian industries.

Typical Applications of Gantry Cranes in Russia

Seas of Efficiency: Gantry Cranes Dominating Russia's Ports and Shipping Hubs

Immerse yourself in the efficiency of gantry cranes as they take center stage in Russia's ports, orchestrating the smooth flow of goods and contributing to the dynamic landscape of the nation's trade dynamics.

Crane Requirement of the Industrial Sector in Russia:

The industrial sector in Russia relies heavily on the efficiency of gantry cranes in ports. These cranes serve as the lifelines of maritime trade, ensuring timely loading and unloading of cargo ships and facilitating the seamless movement of goods through the nation's vital ports.

Types of Gantry Cranes Used:

In the bustling ports of St. Petersburg, Novorossiysk, and beyond, various types of gantry cranes find their application. From Rubber-Tired Gantry Cranes (RTG) ensuring mobility to Rail Mounted Gantry Cranes (RMG) optimizing track-based operations, each type plays a unique role in enhancing port efficiency.

Typical Functions and Application:

Gantry cranes in ports handle a myriad of functions, from unloading containers from ships to precisely stacking them in storage yards. Their ability to handle diverse cargo sizes and weights makes them indispensable in meeting the versatile demands of Russia's maritime trade.

Typical Industrial Crane Project Locations:

Major port cities like Vladivostok and Murmansk witness strategic deployments of gantry cranes, ensuring the efficiency of cargo handling operations. These cranes are pivotal in enhancing the capacity and capabilities of Russia's ports, contributing to the nation's position in the global trade aren

In the maritime realm of efficiency, gantry cranes in Russia's ports stand as beacons, navigating the seas of trade with precision and power. Their role is not just in handling cargo; it's in shaping the very dynamics of Russia's global connectivity and economic prowess.

Forging Strength: Gantry Cranes Powering Russia's Steel and Metallurgical Giants

Enter the realm of industrial might as gantry cranes take center stage, powering the material handling processes of Russia's steel and metallurgical giants. This segment unveils the pivotal role these cranes play in shaping the strength and efficiency of the nation's steel and metallurgy sector.

Crane Requirement of the Industrial Sector in Russia:

In the vast steel plants of Magnitogorsk and the metallurgical complexes of Chelyabinsk, gantry cranes are indispensable. They form the backbone of material handling, ensuring the seamless movement of raw materials and finished products within these critical industrial hubs. Check gantry crane used for steel raw material handling.

Types of Gantry Cranes Used:

The steel and metallurgy sector demands robust solutions, and gantry cranes rise to the occasion. Double Girder Gantry Cranes, with their heavy-duty excellence, dominate these industrial landscapes, handling molten metal, slabs, and other hefty materials with precision.

Typical Functions and Application:

Gantry cranes in steel and metallurgical plants are engaged in a spectrum of tasks, from lifting and transporting raw materials to precise positioning in the manufacturing process. Their strength and reliability contribute to the continuous and efficient operation of these industrial giants.

Typical Industrial Crane Project Locations:

The industrial landscapes of Nizhny Novgorod and Lipetsk witness the towering presence of gantry cranes, ensuring the steady flow of materials in the intricate processes of steel production. These cranes become integral partners in forging the strength that defines Russia's steel and metallurgical prowess.

In the crucible of steel and metallurgy, gantry cranes emerge as the silent architects of strength. Their power and precision are not just tools of material handling; they are keystones in the foundation of Russia's industrial might, forging a path toward excellence in steel production.

Construction and Infrastructure

Building Tomorrow: Gantry Cranes at the Core of Russia's Construction and Infrastructure Projects

Embark on a journey of construction and progress as gantry cranes take center stage, becoming the backbone of Russia's ambitious construction and infrastructure projects. This section unravels the integral role these cranes play in shaping the nation's skyline and building a foundation for tomorrow.

Crane Requirement of the Industrial Sector in Russia:

In the dynamic construction zones of Moscow, St. Petersburg, and beyond, gantry cranes are essential players. They facilitate the vertical growth of buildings, the assembly of infrastructure, and the overall development of the nation's urban landscape.

Types of Gantry Cranes Used:

The versatility of gantry cranes shines in the construction sector. Full and Semi Goliath Cranes, with their towering structures, redefine outdoor handling, while Single Girder Gantry Cranes bring precision to material placement. Their collective contribution ensures the seamless progression of construction projects.

Typical Functions and Application:

Gantry cranes in construction sites undertake a myriad of functions, from lifting and placing construction materials to aiding in the assembly of structural components. Their adaptability to different project requirements makes them indispensable in ensuring the smooth execution of construction and infrastructure endeavors.

Typical Industrial Crane Project Locations:

From the iconic developments in Sochi to the sprawling construction projects in Yekaterinburg, gantry cranes mark their presence. Their role is not just in lifting loads but in lifting the aspirations of a nation, contributing to the construction of a future where innovation and progress converge.

In the realm of construction and infrastructure, gantry cranes stand tall as symbols of progress. Their presence on construction sites is not just about lifting materials; it's about lifting the vision of a nation, building tomorrow's skyline, and shaping the physical legacy of Russia's continuous growth.

Manufacturing and Heavy Industry

Machinery in Motion: Gantry Cranes Enhancing Manufacturing in Russia

Step into the heart of manufacturing excellence as gantry cranes become the driving force, keeping machinery in motion and ensuring precision and efficiency in production processes across Russia's manufacturing and heavy industries.

Crane Requirement of the Industrial Sector in Russia:

Manufacturing hubs in cities like Kazan and Ufa rely on the constant motion of machinery, and gantry cranes play a pivotal role. They contribute to the seamless flow of raw materials and finished products, ensuring that manufacturing processes remain efficient and uninterrupte

Types of Gantry Cranes Used:

In the diverse landscape of manufacturing, Single Girder Gantry Cranes emerge as precision performers. Their ability to navigate tight spaces and handle loads with finesse makes them indispensable in the machinery-heavy environments of manufacturing and heavy industry.

Typical Functions and Application:

Gantry cranes in manufacturing settings undertake a range of functions, from transporting raw materials to positioning heavy components in the production line. Their adaptability and precise control contribute to the efficiency of manufacturing processes, ensuring that machinery stays in continuous motion.

Typical Industrial Crane Project Locations:

From the automotive manufacturing plants in Togliatti to the industrial complexes in Samara, gantry cranes stand as silent choreographers of machinery in motion. Their strategic deployment in manufacturing locations underscores their role in enhancing the productivity and output of Russia's manufacturing sector.

In the symphony of manufacturing, gantry cranes take center stage, orchestrating the dance of machinery in motion. Their contribution goes beyond lifting; it's about ensuring that every gear turns seamlessly, every component is in its place, and manufacturing processes unfold with the precision that defines Russia's prowess in heavy industry.

Driving Precision: Gantry Cranes in Russia's Automotive Manufacturing Excellence

Embark on a journey through precision as gantry cranes navigate the intricacies of Russia's automotive industry, providing essential support to achieve manufacturing excellence. This segment unravels the role of these cranes in the dynamic and precision-driven world of automotive manufacturing.

Crane Requirement of the Industrial Sector in Russia:

In the automotive manufacturing hubs of Kaluga and Nizhny Novgorod, gantry cranes are indispensable. They facilitate the precise handling of materials, components, and finished vehicles, contributing to the efficiency and precision demanded by the automotive industry.

Types of Gantry Cranes Used:

Precision is the hallmark of automotive manufacturing, and gantry cranes, especially Single Girder Gantry Cranes, play a crucial role. Their ability to handle loads with finesse and navigate tight spaces aligns perfectly with the demands of the automotive production line.

Typical Functions and Application:

Gantry cranes in the automotive industry are involved in a spectrum of tasks, from lifting and positioning heavy components in the assembly process to transporting finished vehicles within the manufacturing facility. Their precision and adaptability ensure that every stage of the automotive production line meets the highest standards.

Typical Industrial Crane Project Locations:

From the assembly lines in Tolyatti to the manufacturing facilities in Ulyanovsk, gantry cranes are precision partners in Russia's automotive manufacturing excellence. Their presence in these strategic locations highlights their crucial role in supporting the automotive industry's pursuit of precision and efficiency.

In the world of automotive manufacturing, where precision is paramount, gantry cranes become the drivers of excellence. Their ability to navigate the intricate processes of vehicle production with finesse ensures that each vehicle rolls off the assembly line with the precision and quality that define Russia's automotive industry.

Aerospace Industry

Sky's the Limit: Gantry Cranes Paving the Way for Excellence in Russia's Aerospace Sector

Ascend to new heights as gantry cranes take center stage, playing a pivotal role in elevating the standards of Russia's aerospace industry. This section unveils the critical role these cranes play in reaching for the skies and achieving excellence in aerospace manufacturing.

Crane Requirement of the Industrial Sector in Russia:

In the precision-driven world of aerospace manufacturing in cities like Moscow and Samara, gantry cranes are indispensable. They contribute to the delicate and exacting processes involved in building and assembling components for the aerospace sector.

Types of Gantry Cranes Used:

Goliath Cranes, with their towering structures, find application in the aerospace industry, lifting and positioning large components with precision. Their ability to handle substantial loads makes them ideal for the unique demands of aerospace manufacturing.

Typical Functions and Application:

Gantry cranes in the aerospace sector are engaged in a variety of tasks, from transporting delicate components to assembling large structures. Their precision control and ability to handle materials with care ensure that the exacting standards of the aerospace industry are met at every stage of production.

Typical Industrial Crane Project Locations:

From the aerospace research centers in Zhukovsky to the manufacturing facilities in Ufa, gantry cranes stand as guardians of precision in Russia's aerospace sector. Their strategic placement in these locations underscores their role in supporting the aerospace industry's pursuit of excellence and innovation.

In the boundless skies of the aerospace industry, gantry cranes become instruments of precision and reliability. Their towering presence and precise handling contribute to the realization of ambitious aerospace projects, pushing the boundaries of what is possible and paving the way for excellence in Russia's aerospace sector.

Container Yards and Logistics Centers

Container Revolution: Gantry Cranes Streamlining Logistics in Russia

Step into the era of logistics revolution as gantry cranes take the spotlight, streamlining container yards and ensuring the efficient movement and storage of goods. This segment unravels the transformative role these cranes play in reshaping the logistics landscape across Russi

Crane Requirement of the Industrial Sector in Russia:

In the bustling logistics centers of Novosibirsk and Yekaterinburg, gantry cranes emerge as logistical linchpins. Their role is pivotal in handling containers with speed and precision, facilitating the seamless movement of goods in and out of these critical hubs.

Types of Gantry Cranes Used:

Rubber-Tired Gantry Cranes (RTG) and Rail Mounted Gantry Cranes (RMG) are the workhorses in container yards, providing the mobility and efficiency required for handling containers. Their ability to navigate tight spaces and optimize stacking contributes to the container revolution in logistics.

Typical Functions and Application:

Gantry cranes in container yards are involved in a multitude of tasks, from unloading containers from trucks and ships to stacking them with precision. Their adaptability to different container sizes and weights makes them indispensable in meeting the dynamic demands of logistics operations.

Typical Industrial Crane Project Locations:

From the logistics hubs in Kazan to the container yards in Vladivostok, gantry cranes stand tall as logistical architects. Their strategic placement in these locations ensures the smooth flow of goods, contributing to the efficiency and success of Russia's logistics and supply chain networks.

In the container revolution of logistics, gantry cranes become the driving force, ensuring that goods move seamlessly through the intricate web of supply chain operations. Their efficiency and adaptability mark a transformative era in logistics, streamlining processes and contributing to the evolution of Russia's logistical landscape.

Energy Sector

Powerful Partnerships: Gantry Cranes in Russia's Energy Sector Development

Embark on a journey through powerful partnerships as gantry cranes join forces with Russia's energy sector, playing a crucial role in the nation's energy development. This segment unveils the integral role these cranes play in supporting and advancing the energy sector across Russi

Crane Requirement of the Industrial Sector in Russia:

In the expansive energy facilities of Surgut and Tyumen, gantry cranes are indispensable partners in material handling. They contribute to the efficient movement of heavy equipment, components, and materials, supporting the seamless operation and development of the energy sector.

Types of Gantry Cranes Used:

Double Girder Gantry Cranes, with their heavy-duty excellence, find application in the energy sector. Their ability to handle substantial loads makes them ideal for lifting and placing heavy components in power plants, oil refineries, and other energy-related facilities.

Typical Functions and Application:

Gantry cranes in the energy sector are engaged in a spectrum of tasks, from assembling and maintaining power generation equipment to handling raw materials for energy production. Their precision control and reliability ensure that the energy sector operates with efficiency and meets the demands of the nation's power needs.

Typical Industrial Crane Project Locations:

From the power plants in Kaliningrad to the oil refineries in Nizhnekamsk, gantry cranes stand tall as silent partners in Russia's energy sector development. Their strategic deployment in these locations underscores their vital role in supporting the energy industry's pursuit of reliable and efficient power generation.

In the realm of energy sector development, gantry cranes become powerful allies. Their robust design and precision handling contribute to the growth and efficiency of power generation and oil production, forging powerful partnerships that illuminate the path toward a future powered by the strength of Russia's energy sector.

Industrial Applications and Project Locations of Gantry Cranes in Russia

Key Project Locations

From Moscow to Vladivostok: Gantry Crane Projects Across Russia

Embark on a comprehensive journey across key project locations, unveiling the widespread presence of gantry cranes that stretch from the capital city of Moscow to the bustling eastern port of Vladivostok.

- Crane Projects in Moscow: In the heart of Russia, Moscow stands as a hub of industrial and economic activity. Gantry cranes play a crucial role in various projects across the city, supporting construction, manufacturing, and logistics operations.

- Crane Projects in St. Petersburg: Russia's second-largest city, St. Petersburg, boasts a rich industrial landscape. Gantry cranes contribute to the efficiency of port operations, manufacturing endeavors, and the construction of iconic structures along the Neva River.

- Crane Projects in Novorossiysk: As a major port city on the Black Sea, Novorossiysk plays a pivotal role in international trade. Gantry cranes in this strategic location facilitate the swift handling of containers, supporting the city's prominence in maritime logistics.

- Crane Projects in Vladivostok: Located on the Pacific Ocean, Vladivostok serves as a key gateway to Asi Gantry cranes in Vladivostok's port ensure the smooth flow of goods, contributing to the city's vital role in international trade and transportation.

- Crane Projects in Energy Facilities: From Surgut in Western Siberia to power plants in Kaliningrad, gantry cranes are integral to energy-related projects. They support the construction, maintenance, and operation of facilities crucial to Russia's energy sector.

- Crane Projects in Manufacturing Hubs: Cities like Kazan, Togliatti, and Nizhny Novgorod house manufacturing hubs where gantry cranes are essential. They support the production processes of automotive, steel, and other heavy industries.

- Crane Projects in Logistics Centers: Novosibirsk and Yekaterinburg, as key logistics centers, witness the deployment of gantry cranes. These cranes streamline container handling and logistics operations, ensuring the efficient movement of goods.

- Crane Projects in Construction Zones: Construction zones in cities like Sochi, Yekaterinburg, and Ufa feature gantry cranes in action. These cranes play a pivotal role in lifting and placing materials, contributing to the development of infrastructure and urban landscapes.

Embarking on this journey reveals the omnipresence of gantry cranes, shaping the landscape of Moscow, St. Petersburg, and beyon Their strategic deployment in key project locations underscores their versatility and importance across diverse industries and applications, solidifying their status as indispensable tools for Russia's industrial advancement.

Top Concerns of Gantry Crane Users in Russia

Safety Standards and Compliance

Safety First: Addressing Concerns and Setting Standards in Gantry Crane Operations

Safety takes precedence as we delve into the critical standards and compliance measures essential for gantry crane operations in Russi This section underscores the paramount importance of adhering to stringent safety protocols to ensure the well-being of operators, personnel, and the overall workplace environment.

Safety Standards in Gantry Crane Operations:

Explore the comprehensive safety standards governing gantry crane operations in Russi From load capacity limits to emergency procedures, understanding and adhering to these standards are imperative for a secure working environment.

Operator Training and Certification:

Delve into the training and certification requirements for gantry crane operators. Ensuring that operators are well-trained and certified contributes significantly to accident prevention and the overall safety culture in industrial settings.

Crane Inspection Protocols:

Uncover the detailed inspection protocols for gantry cranes. Regular and thorough inspections are crucial for identifying potential issues before they escalate, promoting proactive maintenance and enhancing overall safety.

Maintenance and Service

Efficiency Uninterrupted: Ensuring Smooth Operations Through Gantry Crane Maintenance in Russia

Efficiency remains uninterrupted as we shine a light on the pivotal role of gantry crane maintenance and service in ensuring smooth operations across industries. This section emphasizes the significance of proactive maintenance to prevent downtime and extend the lifespan of gantry cranes.

Planned Maintenance Schedules:

Explore the importance of planned maintenance schedules for gantry cranes. Regular inspections, lubrication, and part replacements as per a predetermined schedule are essential for preventing unexpected breakdowns.

Emergency Repairs and Downtime Management:

Understand the protocols for emergency repairs and effective downtime management. Quick response to issues and efficient repairs are crucial in minimizing disruptions to industrial processes and maintaining operational continuity.

Lifecycle Management Strategies:

Delve into lifecycle management strategies for gantry cranes. From initial installation to eventual replacement, having a strategic plan for the entire lifecycle ensures optimal performance and cost-effectiveness.

Adaptability to Weather Conditions

Weathering Challenges: How Gantry Cranes Adapt to Russia's Diverse Climate

Explore how gantry cranes overcome the challenges posed by Russia's diverse climate, showcasing adaptability in the face of changing weather conditions. This section highlights the technologies and features that enable gantry cranes to operate seamlessly in varying weather scenarios.

Cold Weather Operation Features:

Discover the specialized features that make gantry cranes suitable for cold weather operation. From anti-freeze systems to insulated components, these adaptations ensure reliable performance in sub-zero temperatures.

Hot Weather Resilience:

Explore how gantry cranes withstand hot weather conditions. Cooling systems, heat-resistant materials, and operational considerations contribute to the resilience of gantry cranes in high-temperature environments.

Wind and Storm Safety Measures:

Understand the safety measures in place for gantry cranes during windy and stormy conditions. Gantry cranes are designed to handle varying wind speeds, and protocols ensure safe operation during adverse weather events.

Addressing these concerns collectively ensures that gantry crane operations in Russia are not only efficient and productive but also prioritize the safety of personnel and the longevity of equipment.

Questions and Answers on Gantry Crane Operation in Russia

How to Choose the Right Gantry Crane for Specific Industries

Tailoring Solutions: Answers to Selecting the Ideal Gantry Crane for Your Industry in Russia

Embark on a journey of decision-making with expert insights on selecting the ideal gantry crane tailored to specific industries in Russi This section provides comprehensive answers to key questions, guiding industries in making informed choices that align with their unique operational needs.

Industry-specific Crane Requirements:

Understand the specific requirements of different industries, from automotive manufacturing to energy production. Tailoring gantry crane features to match industry needs is crucial for optimal performance.

Considerations for Load Capacity:

Explore the considerations for determining the appropriate load capacity of gantry cranes based on industry demands. Matching crane capacity to the weight and size of loads is essential for safe and efficient operations.

Mobility and Space Adaptations:

Delve into how gantry cranes can be adapted for different spaces and mobility requirements. Whether in a compact manufacturing facility or a vast container yard, choosing the right mobility features is essential for seamless operations.

Optimizing Gantry Crane Efficiency

Operational Excellence: Tips and Tricks for Optimizing Gantry Crane Efficiency in Russia

Unlock the secrets to operational excellence as we provide tips and tricks for optimizing the efficiency of gantry cranes in Russi This section offers practical insights into enhancing crane performance and maximizing productivity.

Efficient Load Handling Techniques:

Explore techniques for efficiently handling different types of loads. From containers to heavy machinery, understanding the best practices for load handling ensures smooth and precise operations.

Technology Integration for Automation:

Discover how technology integration, including automation and smart controls, can enhance gantry crane efficiency. Automation features contribute to faster and more accurate operations, reducing downtime.

Preventive Maintenance Strategies:

Understand the importance of preventive maintenance in optimizing gantry crane efficiency. Regular inspections, lubrication, and proactive part replacements contribute to a well-maintained and high-performing crane.

Navigating Regulatory Requirements

Regulatory Roadmap: Understanding and Navigating Gantry Crane Requirements in Russia

Demystify the regulatory landscape as we provide a roadmap for understanding and navigating the requirements for gantry crane operations in Russi This section offers clarity on compliance measures and ensures that industries adhere to the necessary regulations.

Safety Standards and Compliance:

Navigate the safety standards and compliance measures set for gantry crane operations in Russi Understanding and adhering to these standards are crucial for creating a safe and secure work environment.

Documentation and Reporting Obligations:

Explore the documentation and reporting obligations associated with gantry crane operations. Proper record-keeping ensures transparency and compliance with regulatory requirements.

Regulatory Updates and Changes:

Stay informed about the latest updates and changes in gantry crane regulations. Regularly updating procedures and protocols in response to regulatory changes is essential for maintaining compliance.

Navigating these questions and answers empowers industries to make informed decisions, optimize operations, and ensure compliance with regulatory standards in the dynamic landscape of gantry crane operations in Russi

Conclusion: Your Partner in Elevation

Elevate with Confidence: Your Comprehensive Guide to Gantry Cranes in Russia

As we bring this comprehensive guide to a close, let it resonate that gantry cranes transcend mere machinery; they are your trusted partners in elevation, propelling Russia's industries to new heights of efficiency and success. Whether in the dynamic realms of ports, bustling manufacturing floors, or the transformative landscapes of construction sites, gantry cranes stand resolute, ready to elevate your operations with precision, power, and unwavering reliability.

Embracing Partnership in Progress:

- Precision in Every Lift: Gantry cranes, from Single Girder to Double Girder, exhibit precision in every lift, ensuring that your manufacturing processes are streamlined and optimized for excellence.

- Powering Construction and Infrastructure: In the heart of construction zones, Goliath Cranes and Portal Cranes redefine outdoor handling, contributing to the development of Russia's infrastructure and skyline.

- Streamlining Logistics: Rubber-Tired Gantry Cranes (RTG) and Rail Mounted Gantry Cranes (RMG) orchestrate a revolution in logistics, seamlessly handling containers in bustling ports and container yards.

- Strength in Steel and Metallurgy: In the crucibles of steel and metallurgical plants, gantry cranes forge strength, lifting and transporting heavy materials with the utmost reliability.

- Driving Precision in Automotive: Gantry cranes drive precision in the automotive industry, supporting the manufacturing processes that define Russia's excellence in vehicle production.

- Paving the Way in Aerospace: Soaring to new heights, gantry cranes pave the way for excellence in Russia's aerospace sector, playing a pivotal role in the assembly and maintenance of aerospace components.

- Partners in Energy Sector Development: Amidst the vast energy facilities, Double Girder Gantry Cranes form powerful partnerships, contributing to the development and efficiency of Russia's energy sector.

Your Trusted Guide in Gantry Crane Operations:

As you navigate the diverse industrial landscapes across Moscow, St. Petersburg, Vladivostok, and beyond, let this guide serve as your compass, providing insights into selecting the right gantry crane, optimizing efficiency, and ensuring compliance with regulatory standards.

Remember, gantry cranes are not just lifting solutions; they are the embodiment of progress, reliability, and operational excellence. Elevate with confidence, for gantry cranes are not just machines – they are your indispensable partners in the journey toward unparalleled success in Russia's industrial landscape.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch