Overhead Cranes Russia, Top & Underhung Bridge Cranes for Sale

Overhead cranes for sale Russia. All types of overhead cranes, with single girder & double girder design for workshop or outdoor use 5 ton to 100 ton.

Category: Russia

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Cranes Russia, Top & Underhung Bridge Cranes for Sale

Good Price 1 to 20 Ton Single Girder & 3 Ton to 100 Ton Double Girder Overhead Crane for Industrial Use

Overhead cranes for sale Russia. All types of overhead cranes, with single girder & double girder design for workshop or outdoor use 5 ton to 100 ton.

Comprehensive Guide to Overhead Cranes for Sale in the Russian Market

Russia, with its vast and diverse industrial landscape, relies heavily on overhead cranes to facilitate material handling and streamline various operations across a multitude of industries. Whether in the energy sector, steel production, automotive manufacturing, or even the space industry, overhead cranes are indispensable tools for lifting, moving, and positioning heavy loads with precision. The significance of these machines cannot be overstated, making it imperative for businesses to have a comprehensive understanding of their types, configurations, and applications.

This comprehensive guide is designed to serve as a valuable resource for buyers in the Russian market, regardless of whether they are seasoned professionals or newcomers seeking to make their first overhead crane purchase. Our aim is to provide you with practical information and insights that will help you select the right overhead crane tailored to your specific needs, be it for a particular industrial application or for customization to meet unique requirements.

Understanding Your Overhead Crane Needs in Russia

In the vast and diverse industrial landscape of Russia, the selection of an overhead crane is far from one-size-fits-all. To make an informed choice, it's essential to thoroughly assess the specific requirements of your industrial application. This chapter guides you through the process of understanding your overhead crane needs in Russia, considering various crucial factors.

Assessing Specific Requirements

Before delving into the intricacies of overhead cranes, it is crucial to assess the specific requirements of your industrial application. To determine these needs effectively, consider the following:

- Material Type and Weight: What types of materials will the crane be handling? Determine the weight of the heaviest loads you expect to lift, as this will directly impact the crane's lifting capacity.

- Lifting Capacity: The lifting capacity of an overhead crane is one of the most critical factors. To ensure safe and efficient operation, you must be aware of the maximum weight your crane will need to handle regularly.

- Span: The span refers to the distance between the crane's runway rails. Measuring the span accurately is essential to ensure that the crane can cover the required workspace.

- Lift Height: The lift height is the vertical distance from the floor to the hook. It is essential to determine the maximum height your crane needs to lift materials to facilitate safe and efficient material handling.

- Duty Cycle: Consider how often the crane will be in use. Will it be running continuously or intermittently? Different duty cycles require different crane designs and components.

Unique Features and Environmental Factors

Russian industries are diverse, and the environment in which an overhead crane operates can vary significantly. Consider the following unique features and environmental factors that may influence your overhead crane needs:

- Extreme Weather Conditions: In some regions of Russia, extreme cold temperatures or heavy snowfall are common. This can affect the crane's operation and may require additional features like cold-weather packages or snow shields.

- Hazardous Materials: If your application involves handling hazardous materials, you must ensure that the crane is designed to meet safety and environmental regulations.

- Explosive or Corrosive Environments: Certain industries, such as petrochemicals and chemical processing, may require cranes designed to operate safely in explosive or corrosive environments.

- Clean Room Requirements: Industries like pharmaceuticals and healthcare often demand cranes that meet strict cleanliness and contamination control standards.

- Space Constraints: In some cases, you may have limited space for crane installation. Understanding spatial constraints is vital for selecting the appropriate crane type and configuration.

By thoroughly assessing these specific requirements, unique features, and environmental factors, you'll be better equipped to choose an overhead crane that is tailored to the demands of your industrial application in Russia. This initial step is fundamental in ensuring the efficient and safe operation of your overhead crane.

Your Trusted Overhead Crane Manufacturer & Supplier

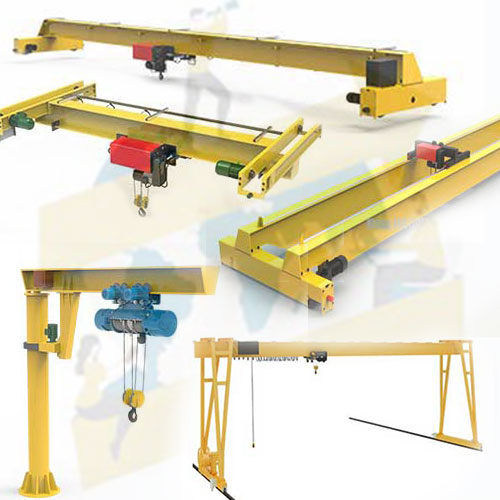

Overhead Crane Types, Designs & Configurations

Russia's diverse industrial landscape demands a range of overhead crane types, each designed for specific applications. This chapter delves into the various types, designs, and configurations of overhead cranes used in Russia. Whether you require a single girder crane for precision or a gantry crane for versatile material handling, understanding the options available is essential for making an informed choice.

- Crane Design & Capacities: Single girder overhead cranes are designed with a single horizontal girder beam. They are available in various capacities, typically ranging from 1 ton to 20 tons.

- Tailored Features for Operation in Russia: These cranes may be equipped with low-temperature lubricants and materials for cold weather operation, snow load capacity, and corrosion-resistant coatings.

- Applicable Industries: Single girder overhead cranes are used in manufacturing, warehouses, and workshops.

- Typical Industrial Locations & Crane Project Locations: Found in industrial areas across Russia, including Moscow, St. Petersburg, and Ekaterinburg.

- Crane Design & Capacities: Double girder overhead cranes feature two parallel girder beams and are designed for heavy lifting. Capacities can range from 5 tons to 200 tons or more.

- Tailored Features for Operation in Russia: These cranes are equipped to handle heavy snow loads, corrosion protection, and are suitable for various heavy industries.

- Applicable Industries: Commonly used in heavy manufacturing, steel mills, and shipyards.

- Typical Industrial Locations & Crane Project Locations: Found in regions with heavy industry, such as Nizhny Novgorod, Chelyabinsk, and Norilsk.

- Crane Design & Capacities: Top running overhead cranes have the bridge running along the top of the runway beams. Capacities vary widely, catering to diverse industrial needs.

- Tailored Features for Operation in Russia: These cranes are designed to withstand snow loads and strong winds. They are often found in the northern regions.

- Applicable Industries: Used in various industries, including manufacturing and warehousing.

- Typical Industrial Locations & Crane Project Locations: Commonly found in industrial zones throughout Russia, such as Samara, Novosibirsk, and Kazan.

- Crane Design & Capacities: Underhung cranes run on the bottom flange of the runway beams and are designed for efficient space utilization. Capacities vary based on specific requirements.

- Tailored Features for Operation in Russia: These cranes are optimized for limited headroom and can be found in areas where overhead space is restricted.

- Applicable Industries: Ideal for workshops and facilities with space constraints.

- Typical Industrial Locations & Crane Project Locations: Used in various manufacturing plants, including those in Stavropol, Ulyanovsk, and Tomsk.

- Crane Design & Capacities: Freestanding overhead cranes are versatile and self-supporting structures. They come in various capacities to suit different applications.

- Tailored Features for Operation in Russia: Designed to meet local regulations and weather conditions, with options for corrosion resistance in humid areas.

- Applicable Industries: Used in manufacturing, warehouses, and maintenance facilities.

- Typical Industrial Locations & Crane Project Locations: Found in regions like Rostov-on-Don, Krasnodar, and Kaluga.

Key Features and Advantages:

- Gantry cranes are versatile, with legs or supports that move on wheels or rails.

- Suitable for outdoor applications and facilities with irregular layouts.

- Can be used in locations without overhead support structures.

Common Tonnages:

Gantry cranes are available in various sizes, with capacities ranging from 1 ton to 100 tons or more.

Typical Industrial Applications:

- Shipping and container handling

- Construction sites

- Lumber yards

Semi Gantry Crane

Key Features and Advantages:

- Semi-gantry cranes have one leg on wheels or rails, making them ideal for facilities with limited space or uneven terrain.

- Offer flexibility for handling loads within specific areas.

Common Tonnages:

Tonnage capacities typically range from 1 ton to 20 tons.

Typical Industrial Applications:

- Manufacturing workshops

- Precise material handling in compact spaces

- Crane Design & Capacities: Single girder gantry cranes have a single horizontal girder and are available in a range of capacities, typically from 1 ton to 20 tons.

- Tailored Features for Operation in Russia: These gantry cranes may include cold-weather features, snow load capacity, and corrosion-resistant components.

- Applicable Industries: Used in outdoor yards, construction sites, and shipping ports.

- Typical Industrial Locations & Crane Project Locations: Found in regions with shipping and outdoor material handling requirements, including Vladivostok, Murmansk, and Novorossiysk.

- Crane Design & Capacities: Double girder gantry cranes have two parallel beams and are suitable for heavy lifting, with capacities ranging from 5 tons to over 200 tons.

- Tailored Features for Operation in Russia: Designed to handle heavy loads, snow loads, and potentially harsh conditions.

- Applicable Industries: Commonly used in heavy industry, shipyards, and large construction projects.

- Typical Industrial Locations & Crane Project Locations: Found in regions with heavy manufacturing and construction activities, such as Nizhnekamsk, Nakhodka, and Vostochny Port.

- Crane Design & Capacities: Portable gantry cranes are mobile and versatile, typically with capacities ranging from 1 ton to 10 tons.

- Tailored Features for Operation in Russia: Designed for easy relocation and may be used in various weather conditions.

- Applicable Industries: Suitable for smaller workshops and temporary material handling needs.

- Typical Industrial Locations & Crane Project Locations: Used in small-scale manufacturing and workshops across the country.

Key Features and Advantages:

- Portable gantry cranes are lightweight and easy to move.

- Ideal for temporary or versatile lifting needs.

- Can be disassembled and relocated as necessary.

Common Tonnages: Portable gantry cranes are typically available in tonnages from 1 ton to 10 tons.

Typical Industrial Applications:

- Workshops and job sites

- Maintenance and repair tasks

- Crane Design & Capacities: Slewing jib cranes have a vertical mast and a horizontal boom. Capacities range from a few hundred kilograms to several tons.

- Tailored Features for Operation in Russia: These cranes are used in various industries, often with customized features.

- Applicable Industries: Found in manufacturing, assembly lines, and maintenance facilities.

- Typical Industrial Locations & Crane Project Locations: Used in numerous factories and workshops throughout Russia.

Key Features and Advantages:

- Slewing jib cranes are wall-mounted or pillar-mounted, providing a rotational range.

- Suitable for precise and localized material handling.

- Offer flexibility for moving loads within a limited area.

Common Tonnages: Tonnage capacities range from 0.25 tons to 5 tons.

Typical Industrial Applications:

- Workstations and assembly areas

- Machine tool shops

- Crane Design & Capacities: Floor jib cranes are anchored to the floor and have a vertical mast with a horizontal boom. Capacities typically range from 0.5 tons to 10 tons.

- Tailored Features for Operation in Russia: These cranes are versatile and suitable for various tasks, including those in cold or humid environments.

- Applicable Industries: Used in manufacturing, assembly, and maintenance facilities.

- Typical Industrial Locations & Crane Project Locations: Found in industrial areas across Russia, including Krasnoyarsk, Ufa, and Novokuznetsk.

Key Features and Advantages:

- Floor jib cranes are floor-mounted and offer a high degree of mobility.

- Provide efficient material handling within designated work areas.

- Suitable for tasks requiring precision.

Common Tonnages: - Tonnage capacities typically range from 0.25 tons to 5 tons.

Typical Industrial Applications:

- Workstations in various industries

- Production lines and work cells

- Crane Design & Capacities: Wall jib cranes are wall-mounted and have a horizontal jib arm for lifting. Capacities typically range from 0.25 tons to 5 tons.

- Tailored Features for Operation in Russia: These cranes are designed for efficient space utilization and can be customized for specific industrial needs.

- Applicable Industries: Found in manufacturing facilities and workshops with limited floor space.

- Typical Industrial Locations & Crane Project Locations: Commonly used in industrial zones in cities like Yekaterinburg, Volgograd, and Tyumen.

Key Features and Advantages:

- Wall jib cranes are attached to a wall or vertical surface.

- Ideal for material handling in confined spaces or where floor space is limited.

- Allow for smooth and efficient lifting within a specific area.

Common Tonnages: - Tonnage capacities typically range from 0.25 tons to 5 tons.

Typical Industrial Applications:

- Machine shops

- Assembly lines with restricted floor space

Explosion-Proof Crane

- Crane Design & Capacities: Explosion-proof cranes are designed to operate safely in hazardous environments with the risk of explosive gases or materials. Capacities vary based on specific requirements.

- Tailored Features for Operation in Russia: These cranes are equipped with explosion-proof components and are essential in industries such as petrochemicals and mining.

- Applicable Industries: Used in potentially explosive environments, such as oil refineries and chemical plants.

- Typical Industrial Locations & Crane Project Locations: Found in areas with high-risk zones in cities like Nizhnevartovsk, Novy Urengoy, and Murmansk.

Corrosion-Resistant Crane

- Crane Design & Capacities: Corrosion-resistant cranes are designed to withstand exposure to corrosive elements, such as saltwater. Capacities depend on the specific needs.

- Tailored Features for Operation in Russia: These cranes have anti-corrosion coatings and materials for extended durability in humid or coastal regions.

- Applicable Industries: Used in facilities near water bodies, such as ports and shipyards.

- Typical Industrial Locations & Crane Project Locations: Found in regions with maritime activity, including Kaliningrad, Arkhangelsk, and Vladivostok.

Magnetic Overhead Crane

- Crane Design & Capacities: Magnetic overhead cranes are equipped with electromagnetic lifting systems. Capacities vary based on the magnetic lifting requirements.

- Tailored Features for Operation in Russia: These cranes are used for lifting and transporting ferrous materials in steel mills, scrap yards, and metalworking industries.

- Applicable Industries: Commonly found in metalworking and recycling facilities.

- Typical Industrial Locations & Crane Project Locations: Used in various industrial zones across Russia, including Lipetsk, Cherepovets, and Magnitogorsk.

Grab Bucket Overhead Cranes

- Crane Design & Capacities: Grab bucket overhead cranes are equipped with specialized buckets for bulk material handling. Capacities depend on the type and density of materials being handled.

- Tailored Features for Operation in Russia: These cranes are customized for specific materials and often used in applications like ore handling and bulk cargo.

- Applicable Industries: Found in mining, port operations, and heavy materials processing facilities.

- Typical Industrial Locations & Crane Project Locations: Used in areas with significant mining and port activities, including Murmansk, Krasnoyarsk, and Kemerovo.

Understanding these crane types, their key features, advantages, and tonnage capacities is crucial for selecting the right overhead crane for your specific application in Russia. Stay tuned for the next chapter, where we explore how these crane types find applications across various industries.

These specialized overhead crane options cater to specific industrial needs, ensuring safety, efficiency, and compliance with regulatory requirements in various regions of Russia.

Typical used and Hot Sale tonnages,

In Russia, several typical used and hot sale tonnages, crane designs, and configurations of overhead cranes are prevalent across various industrial sectors. These configurations are adapted to suit specific applications and industries. Here are some of the most common ones:

5 Ton Single Girder Overhead Crane

- Design & Configuration: Single girder overhead cranes with a 5 Ton capacity are widely used in manufacturing, maintenance, and material handling operations.

- Applications: These cranes are suitable for smaller manufacturing facilities, warehouses, and workshops.

10 Ton Double Girder Overhead Crane

- Design & Configuration: Double girder overhead cranes with a 10 Ton capacity are known for their strength and stability, making them ideal for heavy lifting.

- Applications: These cranes are commonly found in steel mills, metallurgical plants, and construction sites.

20 Ton Gantry Crane

- Design & Configuration: Gantry cranes with a 20 Ton capacity are versatile and used in both indoor and outdoor settings.

- Applications: These cranes are often used in shipyards, ports, and heavy manufacturing facilities.

30 Ton Top Running Overhead Crane

- Design & Configuration: Top running overhead cranes with a 30 Ton capacity are equipped with top-mounted hoists for efficient material handling.

- Applications: These cranes are used in various industries, including automotive manufacturing and foundries.

50 Ton Semi Gantry Crane

- Design & Configuration: Semi gantry cranes with a 50 Ton capacity have one end supported by a structure, allowing for flexible material handling.

- Applications: These cranes are used in open-air storage facilities, shipyards, and large construction sites.

10 Ton Jib Crane

- Design & Configuration: Jib cranes with a 10 Ton capacity have a vertical mast and a horizontal boom, making them suitable for precision lifting.

- Applications: Jib cranes are found in manufacturing and maintenance facilities for tasks like assembly and material handling.

5 Ton Wall Jib Crane

- Design & Configuration: Wall-mounted jib cranes with a 5 Ton capacity save floor space by attaching directly to a wall.

- Applications: These cranes are used in workshops, small manufacturing units, and facilities with limited space.

3 Ton Portable Gantry Crane

- Design & Configuration: Portable gantry cranes with a 3 Ton capacity are mobile and easy to transport within a facility.

- Applications: These cranes are suitable for small workshops, temporary material handling needs, and versatile job sites.

2 Ton Grab Bucket Overhead Crane

- Design & Configuration: Overhead cranes with grab bucket attachments are designed for bulk material handling.

- Applications: These cranes are used in mining, port operations, and facilities handling bulk cargo.

5 Ton Magnetic Overhead Crane

- Design & Configuration: Magnetic overhead cranes are equipped with electromagnetic lifting systems.

- Applications: These cranes are used in metalworking industries for transporting ferrous materials.

These are just some of the typical used and hot sale tonnages and crane designs in Russia. The choice of an overhead crane design and capacity depends on the specific needs of the industry and the application, as well as environmental conditions and safety requirements. Customization options are also available to meet unique requirements in various sectors.

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Cranes for Specific Industrial Sectors

As Russia's industrial landscape continues to thrive, a wide array of sectors demands specialized overhead crane solutions to address their unique requirements. This chapter delves into the application of overhead cranes across various industrial sectors in Russia, offering insights into their specific demands, commonly used tonnages, and real-world examples of crane applications.

Energy and Natural Resources

- Industrial Overview: Russia is renowned for its vast natural resources. The energy sector encompasses oil, natural gas, coal, and nuclear energy. The extraction and processing of these resources are crucial to the Russian economy.

- Specific Requirements: Overhead cranes in this sector must withstand the rigors of heavy lifting in oil refineries, coal mines, and energy facilities.

- Common Tonnages: Tonnages can range from 5 tons to 20 tons or more.

- Notable Applications: Handling heavy equipment in oil refineries, transporting materials in coal mines.

- Location in Russia: The energy sector is distributed throughout the country, with major oil and gas fields in regions like Western Siberia and the Russian Far East.

- Types of Overhead Cranes Used: In this sector, top running overhead cranes and gantry cranes are commonly used.

- Typical Crane Design & Capacity: Cranes in this sector are often heavy-duty, with capacities ranging from 10 tons to 200 tons or more.

- Typical Functions and Applications: Overhead cranes are used for material handling in oil refineries, gas processing plants, and nuclear facilities, including lifting heavy equipment and transporting materials for drilling and extraction.

- Typical Industrial Crane Project Locations: You can find overhead cranes in key energy regions such as Tyumen, Surgut, and Sakhalin Island.

Aerospace and Defense

Industrial Overview: Russia has a robust aerospace and defense industry, producing military equipment, aircraft, and space technology. It's home to renowned entities like Roscosmos and major defense corporations.

- Specific Requirements: Precision and reliability are paramount in aerospace and defense, necessitating overhead cranes for assembling aircraft and rockets.

- Common Tonnages: Tonnages often range from 5 tons to 15 tons.

- Notable Applications: Assembling aircraft components, launching rocket payloads.

- Location in Russia: Aerospace and defense facilities are located in various regions, with a concentration in Moscow, Samara, and Omsk.

- Types of Overhead Cranes Used: Overhead cranes in this sector include bridge cranes and jib cranes, often with special features like explosion-proof components.

- Typical Crane Design & Capacity: Cranes vary in design and capacity to handle delicate aerospace components or heavy military equipment.

- Typical Functions and Applications: Cranes are used for the assembly of aircraft, rockets, and defense equipment, as well as for transporting sensitive payloads.

- Typical Industrial Crane Project Locations: Aerospace and defense complexes can be found in cities such as Komsomolsk-on-Amur, Novosibirsk, and Voronezh.

Automotive Manufacturing

- Industrial Overview: The automotive sector includes the production of cars, trucks, and other vehicles. Russian automobile manufacturers and foreign companies with local operations contribute to this sector.

- Specific Requirements: Overhead cranes are vital in the automotive sector for transporting vehicle components and finished products along production lines.

- Common Tonnages: Tonnages typically range from 1 ton to 10 tons.

- Notable Applications: Conveying engine blocks, positioning car bodies during assembly.

- Location in Russia: Automotive manufacturing plants are spread across the country, with significant operations in Kaluga, Togliatti, and Moscow.

- Types of Overhead Cranes Used: Single and double girder bridge cranes are commonly used in automotive manufacturing.

- Typical Crane Design & Capacity: Cranes in this sector range from 1 ton to 30 tons or more.

- Typical Functions and Applications: Overhead cranes are used in the assembly of vehicles, moving components on the production line, and handling heavy materials.

- Typical Industrial Crane Project Locations: You'll find automotive manufacturing plants in regions like Kaluga, St. Petersburg, and Nizhny Novgorod.

Metallurgy and Steel Production

- Industrial Overview: Russia is one of the world's leading steel producers. It has a strong metallurgical industry, producing steel, aluminum, and other metals for domestic use and export.

- Specific Requirements: Overhead cranes play a pivotal role in handling heavy materials, facilitating material processing, and supporting steel production.

- Common Tonnages: Tonnages commonly range from 10 tons to 20 tons.

- Notable Applications: Moving molten metal, transporting steel coils.

- Location in Russia: Metallurgical plants are distributed throughout the country, including regions like Chelyabinsk, Krasnoyarsk, and Lipetsk.

- Types of Overhead Cranes Used: Double girder overhead cranes are common in steel production, as they handle heavy loads efficiently.

- Typical Crane Design & Capacity: Cranes in this sector can have capacities ranging from 10 tons to 150 tons or more.

- Typical Functions and Applications: Overhead cranes are used in various processes, such as moving raw materials, pouring molten metal, and handling finished products.

- Typical Industrial Crane Project Locations: Metallurgical facilities can be found in cities like Magnitogorsk, Nizhny Tagil, and Novokuznetsk.

Chemical and Petrochemicals

- Industrial Overview: Chemical manufacturing encompasses the production of chemicals, plastics, and fertilizers. The petrochemical sector is closely tied to the country's vast oil and gas reserves.

- Specific Requirements: Overhead cranes in this sector operate in potentially hazardous environments, requiring adherence to stringent safety standards.

- Common Tonnages: Tonnages can vary but typically range from 3 tons to 15 tons.

- Notable Applications: Handling chemical drums, moving equipment in chemical processing.

- Location in Russia: Chemical and petrochemical plants are often situated near oil and gas fields, with operations in areas like Nizhnekamsk, Tobolsk, and Novokuibyshevsk.

- Types of Overhead Cranes Used: Overhead cranes used in this sector may include explosion-proof features and corrosion-resistant components.

- Typical Crane Design & Capacity: Cranes in chemical and petrochemical plants range from 2 tons to 20 tons or more.

- Typical Functions and Applications: Cranes are used for material handling in the production of chemicals, plastics, and other products, often in hazardous environments.

- Typical Industrial Crane Project Locations: You'll find chemical and petrochemical facilities near oil-rich regions such as Tatarstan, Tyumen, and Samara.

Machinery and Heavy Equipment

- Industrial Overview: The manufacturing of machinery, industrial equipment, and heavy machinery is essential to various industries, including construction, mining, and manufacturing.

- Specific Requirements: Versatile and durable cranes are essential for the assembly of heavy machinery and equipment.

- Common Tonnages: Tonnages often range from 2 tons to 15 tons.

- Notable Applications: Assembling heavy machinery components, positioning industrial equipment.

- Location in Russia: Machinery and equipment manufacturing plants are dispersed across the country, including areas like Krasnoyarsk, Tula, and Vladimir.

- Types of Overhead Cranes Used: Single and double girder bridge cranes are common, tailored to various industrial needs.

- Typical Crane Design & Capacity: Cranes in this sector can range from 2 tons to 50 tons or more, depending on the application.

- Typical Functions and Applications: Overhead cranes are used for the assembly of heavy machinery, moving equipment in production, and transporting materials.

- Typical Industrial Crane Project Locations: Manufacturing facilities for heavy equipment are located in regions such as Ural, Siberia, and Central Russia.

Agriculture and Food Processing

- Industrial Overview: Russia has a significant agriculture sector, producing wheat, grains, and various food products. Food processing includes the production of dairy, meat, and processed food items.

- Specific Requirements: Overhead cranes facilitate material handling and food processing tasks, requiring precision and cleanliness.

- Common Tonnages: Tonnages can range from 1 ton to 5 tons.

- Notable Applications: Lifting and conveying agricultural products, positioning food processing equipment.

- Location in Russia: Agriculture and food processing facilities are found in regions with fertile farmland, including areas like Krasnodar, Rostov-on-Don, and Belgorod.

- Types of Overhead Cranes Used: Single and double girder bridge cranes, as well as jib cranes, are used in this sector.

- Typical Crane Design & Capacity: Cranes typically range from 1 ton to 10 tons, catering to different tasks within food processing facilities.

- Typical Functions and Applications: Overhead cranes are used for material handling, including transporting agricultural products and aiding in food processing tasks.

- Typical Industrial Crane Project Locations: You'll find these facilities in agriculturally rich regions across Russia, including the Black Sea coast, Volga region, and Southern Russia.

Construction and Building Materials

- Industrial Overview: Given Russia's construction activities, there's a strong demand for building materials like cement, steel, and construction equipment.

- Specific Requirements: Overhead cranes are crucial for moving construction materials and equipment, often in environments with restricted space.

- Common Tonnages: Tonnages typically range from 2 tons to 10 tons.

- Notable Applications: Handling construction materials, positioning heavy building components.

- Location in Russia: Construction materials manufacturing facilities are scattered across the country, with a strong presence in Moscow, St. Petersburg, and Tatarstan.

- Types of Overhead Cranes Used: Overhead cranes used in this sector are often freestanding or top running bridge cranes, as well as gantry cranes.

- Typical Crane Design & Capacity: Cranes in this sector are designed for various tasks and may have capacities ranging from 5 tons to 30 tons.

- Typical Functions and Applications: Overhead cranes are used for material handling, including transporting construction materials and equipment within these facilities.

- Typical Industrial Crane Project Locations: Construction materials manufacturing plants are commonly found in major cities and regions with infrastructure development, including Moscow, St. Petersburg, and Yaroslavl.

Pharmaceuticals and Healthcare

- Industrial Overview: The pharmaceutical industry in Russia focuses on the production of pharmaceuticals, medical equipment, and healthcare services.

- Specific Requirements: Overhead cranes in these sectors must adhere to strict cleanliness and contamination control standards.

- Common Tonnages: Tonnages often range from 1 ton to 5 tons.

- Notable Applications: Material handling in pharmaceutical manufacturing, precise positioning of healthcare equipment.

- Location in Russia: Pharmaceutical and healthcare facilities are often located in major cities like Moscow, St. Petersburg, and Novosibirsk.

- Types of Overhead Cranes Used: Cranes in this sector are typically workstation bridge cranes and jib cranes for specialized tasks.

- Typical Crane Design & Capacity: Cranes in pharmaceutical and healthcare settings are designed for precision and may have capacities ranging from 0.5 tons to 5 tons.

- Typical Functions and Applications: Overhead cranes are used for handling sensitive medical equipment, materials, and pharmaceutical products.

- Typical Industrial Crane Project Locations: You'll find these facilities in metropolitan areas and key healthcare centers, including Moscow, St. Petersburg, and Novosibirsk.

Information Technology and Software

- Industrial Overview: The IT and software sectors have been growing steadily, with a focus on software development, cybersecurity, and IT services.

- Specific Requirements: Overhead cranes support IT infrastructure by moving server equipment, ensuring delicate handling and precise positioning.

- Common Tonnages: Tonnages typically range from 1 ton to 3 tons.

- Notable Applications: Installing and maintaining server racks, handling IT components.

- Location in Russia: IT and software companies are concentrated in major technology hubs, including Moscow, St. Petersburg, and Novosibirsk.

- Types of Overhead Cranes Used: Overhead cranes may be used in data centers and server facilities for equipment maintenance.

- Typical Crane Design & Capacity: Cranes in IT and software settings are used for maintenance tasks and may have capacities ranging from 0.5 tons to 3 tons.

- Typical Functions and Applications: Overhead cranes are used for handling server equipment and ensuring efficient maintenance of IT infrastructure.

- Typical Industrial Crane Project Locations: IT and software companies are primarily located in technology clusters in cities such as Moscow, St. Petersburg, and Novosibirsk.

Transportation and Logistics

- Industrial Overview: The transportation sector, including railways and shipping, plays a vital role in the distribution of goods throughout this vast country.

- Specific Requirements: Overhead cranes are essential for maintenance and material handling in key logistics centers, demanding efficiency and reliability.

- Common Tonnages: Tonnages often range from 2 tons to 10 tons.

- Notable Applications: Loading and unloading cargo, positioning materials in logistics hubs.

- Location in Russia: Transportation and logistics facilities are situated in key transportation hubs, including Moscow, Novosibirsk, and Krasnoyarsk.

- Types of Overhead Cranes Used: Overhead cranes are used in maintenance facilities and for handling goods in logistics centers.

- Typical Crane Design & Capacity: Cranes in this sector have various designs and capacities, depending on their specific application.

- Typical Functions and Applications: Overhead cranes are used for maintenance tasks and efficient material handling, such as loading and unloading cargo.

- Typical Industrial Crane Project Locations: Transportation and logistics centers are found in major cities and key transportation hubs, including Moscow, Novosibirsk, and Vladivostok.

Forestry and Wood Products

- Industrial Overview: Russia has extensive forests, which support the production of lumber, paper, and wood products.

- Specific Requirements: Overhead cranes aid in the movement of logs, timber, and wood products, requiring versatility and durability.

- Common Tonnages: Tonnages typically range from 2 tons to 10 tons.

- Notable Applications: Lifting and positioning logs, handling wood products.

- Location in Russia: Forestry and wood processing facilities are located in forest-rich regions, including areas like Arkhangelsk, Karelia, and Krasnoyarsk.

- Types of Overhead Cranes Used: Gantry cranes and jib cranes are used for material handling in these facilities.

- Typical Crane Design & Capacity: Cranes are designed for wood processing tasks and can have capacities ranging from 2 tons to 20 tons.

- Typical Functions and Applications: Overhead cranes are used for the movement of logs, timber, and wood products in lumber yards and processing plants.

- Typical Industrial Crane Project Locations: Facilities are primarily situated in regions with significant forest resources, including Arkhangelsk, Karelia, and Krasnoyarsk.

Special Industrial Sectors (Space Industry)

- Industrial Overview: One of the most distinctive industrial sectors in Russia is the space industry. Russia has a long history of space exploration, with achievements such as launching the first artificial satellite, Sputnik, and sending the first human, Yuri Gagarin, into space. The space industry continues to be a point of national pride and innovation.

- Specific Requirements: The space industry relies on specialized cranes for assembling rockets and spacecraft, demanding precision and safety.

- Common Tonnages: Tonnages often range from 5 tons to 15 tons.

- Notable Applications: Assembling rockets, positioning satellite components.

- Location in Russia: Space industry facilities are primarily located in cities like Moscow, Samara, and Baikonur.

- Types of Overhead Cranes Used: Overhead cranes in the space industry include specialized cranes for assembling spacecraft and launching equipment.

- Typical Crane Design & Capacity: These cranes are designed for precision and are customized for tasks related to space technology.

- Typical Functions and Applications: Overhead cranes in the space industry are used for assembling rockets, spacecraft, and launch equipment.

- Typical Industrial Crane Project Locations: The space industry facilities are situated in key locations associated with space exploration, including Moscow, Samara, and Baikonur.

Understanding how overhead cranes are applied in these diverse sectors provides invaluable insights for making informed decisions when selecting the right crane for your specific industrial application in Russia. Stay tuned for the following chapters, which explore customization, top considerations, frequently asked questions, and more.

Your Trusted Overhead Crane Manufacturer & Supplier

Customization and Tailored Solutions in Russia

In the dynamic industrial landscape of Russia, the need for overhead cranes that cater to unique requirements is paramount. This chapter emphasizes the importance of customized overhead cranes and delves into the process of tailoring crane design, capacity, and features to meet specific needs. Real-world examples of customized overhead crane projects in Russia highlight the effectiveness of this approach.

Importance of Customization

Off-the-shelf overhead cranes may not always align perfectly with the demands of your industrial application. Customization offers a solution to bridge the gap between standard crane designs and your specific needs. The significance of customization lies in the following aspects:

- Precision: Tailored overhead cranes can provide precise control and positioning, enhancing productivity and safety.

- Optimal Capacity: Customized cranes can be designed to match the exact lifting capacity required, preventing over-specification and inefficiency.

- Environmental Adaptation: Specialized features can be integrated to address unique environmental factors, such as extreme weather conditions or hazardous materials.

- Spatial Constraints: In facilities with limited space, customized crane designs can make the most of available room without compromising functionality.

Tailoring Crane Design and Capacity

The process of customizing an overhead crane begins with a thorough assessment of your specific needs, as discussed in Chapter Here's how customization is typically carried out:

- Needs Assessment: Understanding your lifting requirements, workspace, and environmental factors is the foundation of customization.

- Design and Engineering: Professional engineers collaborate to create a crane design that aligns with your requirements, considering factors like tonnage, span, and lift height.

- Component Selection: Custom cranes often involve selecting specific components, such as hoists, trolleys, and controls, to meet the application's demands.

- Fabrication and Assembly: The customized crane is fabricated and assembled to meet the design specifications.

- Testing and Validation: Rigorous testing ensures that the crane functions flawlessly, adhering to safety and performance standards.

Showcasing Real-World Examples

Real-world examples demonstrate the practical impact of customization. Here are a few instances of customized overhead crane projects in Russia:

- Specialized Crane for Aerospace Manufacturing: A Russian aerospace company required an overhead crane with precise positioning capabilities to handle delicate aircraft components. A customized double girder crane with advanced control systems was designed to meet their needs, facilitating safe and precise assembly processes.

- Cold-Weather Package for Energy Sector: In a Siberian energy facility, extreme cold is a constant challenge. A customized overhead crane with a cold-weather package, including insulated components and freeze-resistant lubricants, ensures reliable operation even in sub-zero temperatures.

- Explosion-Proof Crane for Petrochemical Industry: A petrochemical plant demanded overhead cranes that could operate in explosive environments. Customized explosion-proof cranes with spark-resistant components and specialized electrical systems were implemented to enhance safety during material handling.

These examples illustrate the transformative power of customization, showcasing how tailored solutions can meet the diverse and unique needs of different industrial applications in Russia. Customization ensures that your overhead crane not only meets but exceeds your expectations, providing the exact features and capacities required for efficient and safe operation.

Top Considerations for Buyers in the Russian Market

Selecting the right overhead crane for your industrial application in Russia is a multifaceted process that involves navigating various considerations. In this chapter, we address the key concerns and considerations for buyers in the Russian market, emphasizing the importance of compliance with local regulations, adherence to safety standards, and the value of post-sale support and maintenance services.

Local Regulations and Compliance

- GOST Standards: Russian industries often adhere to the national GOST standards. It's essential to ensure that the overhead crane you select complies with these standards to guarantee safe and legal operation.

- Customs Regulations: Importing cranes may entail navigating customs and import regulations. Understanding and adhering to these procedures is crucial to ensure a smooth transaction.

Safety Standards

- Safety Compliance: Overhead cranes are subject to rigorous safety standards to protect both personnel and equipment. Buyers should prioritize cranes that adhere to recognized safety regulations and certifications.

- Operator Training: Ensuring that crane operators are adequately trained in safe operation is essential. Many crane manufacturers offer training programs to help operators become proficient.

Certifications

- GOST-R Certification: Russian regulations often require GOST-R certification for imported equipment. Buyers should confirm that the selected crane has this certification to meet local compliance requirements.

- EAC Certification: The Eurasian Conformity (EAC) certification is another critical requirement for certain industrial equipment in Russia and the Eurasian Economic Union (EAEU). Buyers should verify that their chosen crane has this certification.

Post-Sale Support and Maintenance

- Warranty: Understanding the warranty offered by the crane manufacturer or supplier is vital. A comprehensive warranty can provide peace of mind in case of unexpected issues.

- Maintenance Services: Regular maintenance is essential to ensure the longevity and safety of your overhead crane. Buyers should inquire about available maintenance and servicing options.

- Spare Parts Availability: Ensuring that spare parts for your crane are readily available is crucial for minimizing downtime in case of maintenance or repairs.

Supplier Reputation and Expertise

- Supplier Reliability: Choosing a reputable and reliable supplier with a history of successful installations and satisfied customers is a crucial consideration.

- Expertise in Your Industry: Some suppliers specialize in specific industrial sectors. Selecting a supplier with expertise in your industry can lead to more tailored solutions.

Budget and Cost Considerations

- Total Cost of Ownership: While upfront costs are important, buyers should consider the total cost of ownership, including maintenance, energy consumption, and operational efficiency.

- ROI Analysis: Conducting a return on investment (ROI) analysis can help assess the long-term benefits of a crane, considering increased efficiency and productivity.

Navigating these considerations ensures that buyers in the Russian market make well-informed decisions when selecting and procuring overhead cranes. Compliance with local regulations, safety standards, and certifications, along with post-sale support and maintenance, are critical to achieving safe and efficient crane operation while maximizing return on investment.

Your Trusted Overhead Crane Manufacturer & Supplier

Purchasing Overhead Cranes in Russia

Frequently Asked Questions (FAQ)

Purchasing overhead cranes in Russia can be a complex process, and buyers often have questions and concerns. In this chapter, we address the most frequently asked questions related to buying overhead cranes in the Russian market, providing practical answers to assist buyers in making informed decisions.

What types of overhead cranes are commonly used in Russia, and how do I choose the right one for my application?

Answer: The most common types of overhead cranes in Russia include single girder cranes, double girder cranes, gantry cranes, semi-gantry cranes, portable gantry cranes, slewing jib cranes, wall jib cranes, and floor jib cranes. To choose the right one for your application, assess your specific requirements, such as lifting capacity, span, and environmental factors. Consider the insights provided in Chapter 1 and Chapter 2 of this guide.

What certifications and standards should I look for when buying an overhead crane in Russia?

Answer: When purchasing an overhead crane in Russia, look for GOST-R certification, which is essential to comply with national standards. Additionally, ensure that the crane meets the Eurasian Conformity (EAC) certification requirements for compliance in the Eurasian Economic Union (EAEU). These certifications confirm that the crane complies with safety and quality standards.

What are the key considerations when choosing a supplier for an overhead crane in Russia?

Answer: Choosing the right supplier is crucial. Look for a supplier with a good reputation, reliability, and experience in providing overhead cranes for your specific industry. Ensure they offer comprehensive post-sale support, including maintenance services and spare parts availability.

How can I ensure the safety of overhead crane operation in my facility?

Answer: Safety is paramount. Ensure that crane operators are well-trained and certified for safe operation. Regular maintenance and inspections are essential to keep the crane in optimal working condition. Additionally, follow all safety guidelines and standards in your industry.

What should I consider in terms of budget and total cost of ownership when buying an overhead crane in Russia?

Answer: While upfront costs are a significant factor, consider the total cost of ownership, including maintenance, energy consumption, and operational efficiency. Conduct a return on investment (ROI) analysis to assess the long-term benefits of your investment.

Can I customize an overhead crane to meet my specific needs in Russia?

Answer: Yes, customization is an option to tailor the crane to your unique requirements. Work with crane manufacturers and suppliers who offer customization services to design a crane that aligns perfectly with your application.

What is the typical lead time for procuring an overhead crane in Russia?

Answer: The lead time can vary depending on factors like crane type, customization, and supplier availability. It's advisable to discuss the lead time with your chosen supplier to plan your procurement accordingly.

How can I ensure that my overhead crane operates efficiently in extreme weather conditions, such as cold temperatures?

Answer: For extreme weather conditions, consider overhead cranes with cold-weather packages, which include insulated components and freeze-resistant lubricants. These features enhance the crane's reliability in cold climates.

What should I do if I need spare parts for my overhead crane in Russia?

Answer: Ensure that the supplier offers readily available spare parts. Keep a stock of essential spare parts to minimize downtime in case of maintenance or repairs.

Is operator training provided when purchasing an overhead crane in Russia?

Answer: Many crane manufacturers and suppliers offer operator training programs to ensure safe and proficient operation. It's advisable to inquire about available training options.

These frequently asked questions and their answers provide valuable insights for buyers in the Russian market, helping them navigate the complexities of purchasing overhead cranes and making informed decisions that align with their specific needs and requirements.

Buying Overhead Cranes from China for the Russian Market

As the global market continues to evolve, many buyers in Russia are exploring the option of sourcing overhead cranes from China. This chapter offers an analysis of the benefits and limitations of buying overhead cranes from China for the Russian market. It also discusses essential factors, such as cost-effectiveness, lead times, product quality, logistics, and regulatory compliance.

Benefits of Sourcing Overhead Cranes from China

- Cost-Effectiveness: One of the primary advantages of sourcing overhead cranes from China is the cost-effectiveness. Chinese manufacturers often offer competitive pricing, making it an attractive option for buyers looking to optimize their budgets.

- Variety of Suppliers: China boasts a wide range of overhead crane manufacturers, providing buyers with numerous options to choose from. This diversity allows buyers to find a supplier that aligns with their specific requirements and preferences.

- Lead Times: Chinese manufacturers are known for their ability to produce and deliver overhead cranes with relatively short lead times. This can be advantageous for buyers who require quick turnaround times.

- Customization: Chinese manufacturers often provide customization options, allowing buyers to tailor overhead cranes to their exact specifications and application needs.

Limitations of Sourcing Overhead Cranes from China

- Quality Assurance: While China offers competitive pricing, ensuring the quality and reliability of the product can be a concern. Buyers should thoroughly vet manufacturers and request quality assurances.

- Language and Communication Challenges: Communication can sometimes be challenging due to language differences. Effective communication is crucial for specifying requirements and addressing any issues during the procurement process.

- Logistics and Import Challenges: Importing overhead cranes from China can involve complex logistics and regulatory compliance. Navigating customs procedures and ensuring compliance with local regulations are essential steps in the process.

- After-Sale Support: Distance can be a hindrance to efficient after-sale support and maintenance. Buyers should establish clear expectations for post-sale services.

Key Considerations When Importing Overhead Cranes from China to Russia

- Supplier Selection: Carefully select a reputable Chinese manufacturer or supplier with a history of successful exports and a commitment to product quality.

- Quality Assurance: Insist on quality assurances and certifications to ensure that the overhead crane meets safety and performance standards.

- Communication: Establish effective communication channels with the supplier to prevent misunderstandings and facilitate a smooth procurement process.

- Logistics and Compliance: Work with logistics experts who are experienced in shipping heavy equipment. Ensure compliance with Russian regulations and customs requirements.

- After-Sale Support: Discuss post-sale support and maintenance services with the supplier. Clarify expectations regarding service and spare parts availability.

- Shipping and Installation: Plan for the shipping and installation of the crane, considering factors like transportation methods and on-site assembly.

Sourcing overhead cranes from China can be a viable option for buyers in the Russian market, offering cost-effective solutions with the potential for customization. However, it's essential to navigate the limitations and challenges effectively, including quality assurance, communication, logistics, and compliance. By addressing these considerations, buyers can make informed decisions and leverage the advantages of sourcing overhead cranes from China while mitigating potential risks.

Required Documents and Certifications for Importing Overhead Cranes from China to Russia

Importing overhead cranes from China to Russia involves a series of essential documents and certifications to ensure compliance with Russian standards and regulations. In this chapter, we provide an overview of the necessary paperwork and certifications required for a successful importation process, including the significance of certificates like GOST-R and EAC.

- Commercial Invoice -A commercial invoice is a fundamental document that provides details about the transaction, including the value of the overhead crane, the buyer, the seller, and other essential financial information.

- Packing List -The packing list outlines the contents of the shipment, including the types and quantities of overhead cranes, their dimensions, and weights.

- Bill of Lading (B/L) -The bill of lading serves as a receipt of goods from the carrier and evidence of the contract of carriage. It provides information about the shipment's route, the vessel or carrier, and delivery instructions.

- Certificate of Origin -This certificate states the country in which the overhead crane was manufactured. It may be required for customs purposes and to determine eligibility for certain trade agreements or tariffs.

- Technical Documentation -Technical documentation, including product specifications, user manuals, and safety data, is vital to ensure that the overhead crane meets Russian standards and safety regulations.

- Quality Certificates -Quality certificates confirm that the overhead crane complies with specific quality and performance standards. These certificates may be issued by Chinese and Russian authorities or recognized international organizations.

- Customs Declarations -Customs declarations are mandatory for entry into Russia and involve providing information about the shipment's contents, value, and origin.

- GOST-R Certificate -The GOST-R certificate is essential for products entering the Russian market. It confirms compliance with Russian quality and safety standards. For overhead cranes, this certificate ensures that the equipment adheres to GOST standards.

- EAC Certification -The Eurasian Conformity (EAC) certification is vital when importing overhead cranes into Russia and the Eurasian Economic Union (EAEU). It demonstrates compliance with safety and quality requirements within the EAEU.

- Import License and Permits- Import licenses and permits may be required depending on the type and quantity of overhead cranes being imported.

- Transport Documents -Transport documents, such as road permits or railway agreements, may be necessary for the transportation of overhead cranes within Russia.

- Environmental and Safety Certificates -In cases where overhead cranes are designed for specific environments, such as explosion-proof or cold-weather cranes, environmental and safety certificates may be required to ensure their suitability for the intended application.

- EAC Marking -The EAC marking on overhead cranes indicates their compliance with EAEU regulations and standards. This mark is often affixed to the product itself.

- Certificate of Conformity -A certificate of conformity is a document issued by an accredited certification body and attests that the product complies with safety and quality standards.

Ensuring that these documents and certifications are in order is essential for a smooth importation process. It is advisable to work with experienced importers, customs brokers, or legal advisors who are well-versed in Russian import regulations to navigate the complexities of importing overhead cranes into Russia from China successfully.

Transportations

Transporting overhead cranes and gantry cranes with large volume and heavy weight from China to Russia is a complex process that requires careful planning and consideration of various factors. Here are some key points to keep in mind when organizing the transportation of such equipment:

- Transportation Mode: You have several transportation options, including sea freight, road transportation, and rail transportation. The choice depends on the location of the supplier, the final destination in Russia, and the weight and dimensions of the crane. For extremely heavy and oversized cranes, sea freight is often the preferred choice.

- Route Planning: Determine the most efficient and cost-effective transportation route. This includes choosing the departure and arrival ports, road or rail routes, and any necessary transshipment points.

- Customs and Documentation: Ensure that all necessary customs documentation, such as import permits and declarations, is in order. Customs regulations can be complex, so it's advisable to work with experienced customs brokers who can help navigate the process.

- Packaging and Handling: Properly packaging and securing the crane is crucial to prevent damage during transit. The supplier should have experience in preparing cranes for international transport.

- Shipping Container: Depending on the size and weight of the crane, you may need to use specialized shipping containers or flat racks. The choice of container type should align with the crane's dimensions.

- Incoterms: Define the Incoterms (International Commercial Terms) that specify the responsibilities and costs between the buyer and the seller in the transportation process. This helps clarify who is responsible for various aspects of the shipment.

- Import Duties and Taxes: Be aware of the import duties and taxes that apply to the crane when it arrives in Russia. These can vary based on the crane's value, origin, and classification.

- Transport Insurance: Consider obtaining transportation insurance to protect your investment in case of damage or loss during transit. Many logistics companies offer cargo insurance options.

- Logistics Provider: Partner with a reputable logistics provider with experience in handling heavy and oversized cargo. They can help coordinate the entire transportation process and provide valuable guidance.

- Regulatory Compliance: Ensure that the crane complies with all safety and quality standards, including GOST-R and EAC certifications, to avoid issues with Russian customs and regulatory authorities.

- Route and Road Conditions: If road transportation is part of the journey, consider the road conditions and infrastructure in Russia. Some areas may have restrictions on heavy or oversized cargo.

- Lead Time: Plan the lead time carefully to align with your project schedule. International shipping can have variable lead times, so work closely with your logistics provider to coordinate the timing.

- Installation and Assembly: Have a plan in place for the installation and assembly of the crane at its destination in Russia. This may involve hiring local experts and ensuring that the necessary equipment and resources are available.

In summary, transporting large and heavy overhead cranes and gantry cranes from China to Russia is a multifaceted process that requires meticulous planning, documentation, and coordination. Partnering with experienced logistics providers and ensuring compliance with customs regulations and safety standards is crucial to a successful and smooth transportation process.

Your Trusted Overhead Crane Manufacturer & Supplier

Case Studies and Success Stories

In this chapter, we present real-life case studies of Russian companies that have successfully acquired and utilized overhead cranes in their operations. These case studies shed light on their experiences, challenges, and the solutions they implemented, offering valuable insights for prospective overhead crane buyers in Russia.

Metal Processing Facility in Moscow

- Challenge: A metal processing facility in Moscow required efficient material handling solutions to optimize their production processes. They needed overhead cranes that could handle heavy loads and withstand the demanding environment of a metalworking plant.

- Solution: The facility collaborated with a local overhead crane manufacturer to design and install customized double girder overhead cranes equipped with specialized lifting attachments. These cranes provided the required lifting capacity and durability.

- Outcome: The installation of customized overhead cranes significantly improved the facility's material handling efficiency. The cranes increased productivity and reduced downtime, leading to a noticeable impact on the bottom line.

Aerospace Manufacturer in St. Petersburg

- Challenge: An aerospace manufacturer in St. Petersburg needed overhead cranes for assembling aircraft components with the utmost precision. Safety and accuracy were paramount due to the sensitive nature of their work.

- Solution: The aerospace manufacturer partnered with an experienced overhead crane supplier specializing in precision solutions. They implemented double girder cranes with advanced control systems and integrated safety features to ensure precise positioning.

- Outcome: The precision overhead cranes facilitated safe and accurate assembly processes, reducing the risk of errors and accidents. This improvement was crucial in upholding the quality and safety standards expected in aerospace manufacturing.

Mining Company in Siberia

- Challenge: A mining company in Siberia required overhead cranes for material handling in a harsh, cold-weather environment. Extreme temperatures and harsh conditions were a significant challenge.

- Solution: The mining company collaborated with a supplier with expertise in cold-weather solutions. They procured overhead cranes equipped with cold-weather packages, including insulated components and freeze-resistant lubricants.

- Outcome: The cold-weather overhead cranes proved to be highly reliable even in sub-zero temperatures. They played a crucial role in maintaining continuous operations in the challenging Siberian climate.

Petrochemical Plant in Western Russia

- Challenge: A petrochemical plant in Western Russia needed explosion-proof overhead cranes to operate safely in potentially hazardous environments where flammable materials were present.

- Solution: The plant partnered with a supplier specializing in explosion-proof equipment. They acquired overhead cranes with spark-resistant components and specialized electrical systems to enhance safety during material handling.

- Outcome: The installation of explosion-proof overhead cranes improved safety and minimized the risk of accidents in the petrochemical plant. This solution ensured safe operations in the presence of volatile materials.

These case studies highlight the diverse applications of overhead cranes across various industries in Russia. Successful solutions often involve collaboration with experienced suppliers and the customization of cranes to meet specific requirements. By learning from these real-world experiences, prospective buyers can make informed decisions and identify the best-suited overhead crane solutions for their unique needs.

Conclusion and Next Steps

As we conclude this comprehensive guide to purchasing overhead cranes in the Russian market, it's essential to recap key takeaways and considerations that will empower buyers to make informed decisions. We encourage readers to seek expert advice and connect with reputable suppliers for their overhead crane needs, and we offer resources for further information and assistance.

Key Takeaways

- Understanding Your Needs: The first step in acquiring the right overhead crane is a thorough assessment of your specific requirements, including lifting capacity, span, and environmental factors.

- Overhead Crane Types: Russia offers a variety of overhead crane types, each designed for specific applications. Select the one that aligns with your industrial needs and demands.

- Industry-Specific Requirements: Different industrial sectors in Russia have unique requirements and commonly used tonnages for overhead cranes. Knowing these requirements is crucial for a successful procurement process.

- Customization Matters: Customized overhead cranes can provide tailored solutions that enhance efficiency, safety, and productivity in your specific application.

- Compliance and Certifications: Ensure that the overhead crane complies with Russian standards and regulations, including GOST-R and EAC certifications, to avoid legal and safety issues.

- Considerations for Buying from China: Sourcing overhead cranes from China can be cost-effective, but it requires careful supplier selection, quality assurance, and attention to logistics and compliance.

- Documentation and Certifications: Importing overhead cranes from China to Russia involves a range of documents and certifications, such as commercial invoices, quality certificates, and GOST-R certification.

- Safety and Maintenance: Prioritize safety through operator training and regular maintenance. Select suppliers who offer post-sale support and spare parts availability.

To move forward with your overhead crane procurement,

consider the following steps:

- Consult Experts: Seek advice from experts in the field who can guide you through the process, from needs assessment to selecting the right crane type and supplier.

- Connect with Reputable Suppliers: Establish connections with reputable overhead crane manufacturers and suppliers who have a proven track record in the Russian market.

- Prioritize Safety: Prioritize the safety of your operations by ensuring operator training and implementing regular maintenance procedures.

- Thorough Documentation: Ensure that all necessary documentation and certifications are in order, complying with both Russian and international standards.

- Explore Customization: If your application demands unique solutions, explore the possibilities of customizing your overhead crane for maximum efficiency.

- Plan for Maintenance: Plan for ongoing maintenance and spare parts availability to prevent downtime and operational disruptions.

Resources for Further Information and Assistance

- Russian Regulatory Authorities: Connect with Russian regulatory authorities for information on standards, certifications, and compliance requirements.

- Industry Associations: Explore industry-specific associations in Russia for additional guidance and resources.

- Local Consultants: Consider consulting with local experts and consultants who are well-versed in Russian industrial requirements and procurement processes.

- Reputable Suppliers: Engage with reputable overhead crane suppliers who have experience in serving Russian industries.

This guide is designed to equip you with the knowledge and insights needed to make informed decisions when purchasing overhead cranes in the Russian market. By following the key takeaways and next steps, you can embark on a successful journey to acquire the right overhead crane that aligns perfectly with your specific needs and enhances your industrial operations.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch