Bridge Cranes for Machinery Manufacturing: Types & Uses 1- 50 Ton

Bridge Cranes in Machinery Manufacturing

In the intricate world of machinery manufacturing, where precision and efficiency are paramount, the role of bridge cranes stands as a testament to innovation in material handling and assembly. This two-part blog series delves into the various types of bridge cranes that play a pivotal role in the machinery manufacturing industry, highlighting their features, benefits, and applications across diverse aspects of production.

Defining Bridge Cranes and Their Significance

Bridge cranes, also known as overhead cranes, are robust and versatile lifting solutions that traverse overhead runways or beams, allowing them to efficiently move heavy loads across a workspace. These cranes have become the backbone of modern manufacturing processes, addressing the challenges posed by the handling of large components, intricate assemblies, and the need for precise positioning.

The Crucial Role in Efficient Material Handling and Assembly

At the heart of machinery manufacturing lies the need for seamless material handling and assembly processes. Bridge cranes address this need by providing a dynamic and adaptable means of moving materials and components within the manufacturing facility. From lifting raw materials to positioning heavy machinery parts, bridge cranes contribute significantly to streamlining production workflows and optimizing factory space utilization.

Whether it's the assembly of automobiles, the creation of intricate aerospace components, or the fabrication of heavy equipment, bridge cranes have become a silent force that empowers manufacturers to achieve greater efficiency, accuracy, and safety in their operations.

Brief Introduction of Machinery Manufacturing

Machinery manufacturing involves the production of various types of machinery and equipment used in different industries and applications. It encompasses the design, development, fabrication, assembly, and testing of machines that are utilized in sectors such as agriculture, construction, manufacturing, energy, transportation, healthcare, and more. Machinery manufacturing plays a crucial role in driving industrial and technological advancements.

Machinery can range from simple devices to complex systems, and it includes a wide variety of equipment such as:

- Industrial Machinery: This includes equipment used in factories and manufacturing plants, such as CNC machines, assembly line systems, printing presses, and industrial robots.

- Construction Machinery: These are machines used in construction projects, such as excavators, bulldozers, cranes, and concrete mixers.

- Agricultural Machinery: Equipment used in farming and agriculture, like tractors, harvesters, irrigation systems, and plows.

- Energy and Power Machinery: Machines used in power generation and distribution, such as turbines, generators, transformers, and power grid equipment.

- Transportation Machinery: This category covers vehicles and equipment used in transportation, including automobiles, trucks, airplanes, ships, and trains.

- Medical Machinery: Equipment used in the medical and healthcare field, like MRI machines, X-ray equipment, surgical robots, and diagnostic instruments.

- Food Processing Machinery: Machines used in food production and processing, including packaging equipment, food preparation machinery, and beverage processing machines.

- Textile Machinery: Equipment used in the textile industry for processes like spinning, weaving, and dyeing.

- Mining and Construction Machinery: Machinery used in mining operations, including drilling rigs, crushers, and mineral processing equipment.

- Material Handling Machinery: Equipment used for moving and handling materials within warehouses, factories, and distribution centers, such as forklifts and conveyor systems.

Machinery manufacturing involves a combination of engineering disciplines, including mechanical, electrical, and sometimes software engineering. It requires expertise in design, manufacturing processes, materials science, quality control, and safety standards. With advances in technology, machinery manufacturing has evolved to incorporate digital design, automation, and smart technologies to enhance efficiency, precision, and functionality.

The machinery manufacturing industry has a significant impact on economic growth and industrial development, as it provides the tools and equipment necessary for other industries to operate efficiently and effectively.

Why overhead cranes are needed in machinery manufacturing ?

Overhead cranes are an essential tool in the machinery manufacturing industry for several reasons:

- Heavy Lifting: Machinery manufacturing often involves the production of large and heavy components, parts, and machinery. Overhead cranes have the capacity to lift and move these heavy loads safely and efficiently, which would be difficult or impossible to accomplish manually.

- Precision Handling: Overhead cranes are equipped with controls that allow operators to maneuver loads with high precision. This is crucial when assembling intricate machinery that requires accurate alignment and positioning of components.

- Efficient Material Movement: Overhead cranes facilitate the movement of materials and components across different workstations within a manufacturing facility. This helps streamline production processes and reduces the need for manual material handling, saving time and minimizing the risk of damage.

- Optimal Use of Space: Manufacturing facilities often have limited floor space due to the large machinery and equipment present. Overhead cranes operate above the production area, utilizing vertical space effectively and freeing up valuable floor space for other operations.

- Safety and Ergonomics: Overhead cranes contribute to a safer work environment by reducing the need for manual lifting, which can lead to injuries. Operators can control the crane from a safe distance, minimizing their exposure to potentially hazardous situations.

- Versatility: Overhead cranes can be designed with various lifting mechanisms, such as hooks, magnets, or specialized tooling, making them adaptable to different manufacturing processes. This versatility allows them to handle a wide range of loads and tasks.

- High Load Capacity: Overhead cranes are engineered to handle heavy loads that would be impractical or unsafe for traditional material handling methods. This capability is particularly useful in the machinery manufacturing industry, where many components are large and heavy.

- Time Efficiency: Overhead cranes can significantly speed up manufacturing processes by swiftly moving materials and components to where they are needed. This leads to faster production cycles and increased overall productivity.

- Reduced Labor Costs: By automating the lifting and movement of heavy loads, overhead cranes reduce the need for manual labor, which can result in cost savings in the long run.

- Improved Quality: Precise handling and positioning offered by overhead cranes contribute to better quality control during assembly and production processes. This helps prevent errors and defects that can arise from mishandling or misalignment.

Overall, overhead cranes play a vital role in machinery manufacturing by providing the means to handle large and heavy components efficiently, safely, and with precision. Their contributions lead to enhanced productivity, reduced risks, and improved manufacturing processes.

Types of Bridge Cranes in Machinery Manufacturing

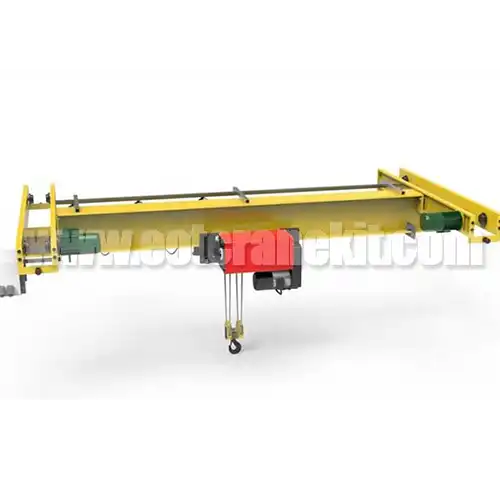

Bridge Cranes (EOT Cranes - Electric Overhead Traveling Cranes):

- Features: Consist of a bridge that travels along elevated runways, with a hoist and trolley for vertical and horizontal movement. Can be single or double girder.

- Benefits: High load capacities, wide coverage area, precise positioning, suitable for heavy-duty tasks.

- Function: Lifting, moving, and positioning heavy components and machinery across a large area.

- Typical Applications: Assembly lines, machining operations, material handling in manufacturing facilities, shipyards, construction sites.

- Features: Similar to bridge cranes but supported by legs on the ground. Can have single or double girder configurations.

- Benefits: Versatile, outdoor use, large coverage area, suitable for open spaces.

- Function: Lifting and moving heavy loads in outdoor areas or where overhead runways are impractical.

- Typical Applications: Construction sites, shipyards, outdoor material handling, large manufacturing facilities.

- Features: Consist of a horizontal arm (jib) mounted to a vertical mast or wall. Can be wall-mounted or freestanding.

- Benefits: Space-saving, localized material handling, easy installation, precise positioning.

- Function: Lifting and moving loads within a confined area, loading and unloading workstations.

- Typical Applications: Workstations, assembly lines, machining centers, loading docks.

- Features: Utilize a single rail for hoist and trolley movement along a fixed path.

- Benefits: Linear material movement, adaptable to various layouts, suitable for repetitive tasks.

- Function: Transporting materials along a predetermined path, automated material handling.

- Typical Applications: Assembly lines, production processes, material transport in confined spaces.

Single Girder Bridge Cranes

In the vast landscape of machinery manufacturing, precision and efficiency are the cornerstones of success. Among the many tools that enable this success, single girder bridge cranes emerge as a versatile and cost-effective solution. Let's delve into the intricacies of these cranes, uncovering their features, benefits, and applications that make them a staple in the industry.

Features of Single Girder Bridge Cranes

Single girder bridge cranes are characterized by their use of a single beam for lifting and movement. This design ensures a streamlined yet robust structure that is ideally suited for specific applications within machinery manufacturing. Additionally, these cranes are engineered to accommodate lighter loads and possess lower headroom requirements, making them adaptable to various production environments.

European Standard Suspension Single Girder Bridge Crane

Lifting capacity of single girder overhead crane: 1ton,3 ton, 5 ton to 10 ton

Span ofsingle girder overhead crane: 3-15 m

Lifting height of single girder overhead crane: 3-100 m

Ask for single girder overhead crane price now.

Suspension Single Girder Bridge Crane Chinese type

Lifting Capacity of Single Girder Bridge Crane: 0.5ton, 3 ton, 5 ton to 10 ton

Span of Single Girder Bridge Crane: 3m to 31.5m

Working Class of Bridge Crane: A3 to A5

Ask for single girder overhead crane price now.

FEM / DIN Top running Single Girder Bridge Crane

Lifting Capacity of Single Girder Bridge Crane: 3.2ton, 3 ton, 5 ton 10 ton ton 16ton

Span of Single Girder Bridge Crane: 7.5m to 28.5m

Working Class of Bridge Crane: A5

Ask for single girder overhead crane price now.

Chinese Style Top Running Single Girder Bridge Crane

Lifting Capacity of Single Girder Bridge Crane: 1ton, 3 ton, 5 ton,10 ton up to 20 ton

Span Length of Single Girder Bridge Crane: 7.5m-28.5m

Working Class of Bridge Crane: A3, A4

Ask for single girder overhead crane price now.

Explosion Proof Single Girder Bridge Crane

Lifting Capacity of Single Girder Crane: 1ton, 3 ton, 5 ton,10 ton up to 20 ton

Span of Single Girder Bridge Crane: 7.5m to 28.5m

Working Class of Bridge Crane: A3, A4

Ask for single girder overhead crane price now.

Partial Hung Low Headroom Single Girder Bridge Crane

Lifting Capacity of Single Girder Bridge Crane: 1ton, 3 ton, 5 ton,10 ton up to32 ton

Span of Single Girder Bridge Crane: 7.5m to 22.5m

Working Class of Bridge Crane: A3, A4

Ask for single girder overhead crane price now.

Low headroom Hoist Single Girder Bridge Crane

Lifting Capacity of Single Girder Bridge Crane: 1ton, 3 ton, 5 ton,10 ton up to32 ton

Span of Single Girder Bridge Crane: 7.5m to 22.5m

Working Class of Bridge Crane: A3, A4

Ask for single girder overhead crane price now.

Ladle handling Single Girder Bridge Crane

Lifting Capacity of Single Girder Bridge Crane: 1ton, 3 ton, 5 ton, 10t

Lifting Height of Single Girder Bridge Crane: 6~18m

Working Class of Bridge Crane: M5

Ask for single girder overhead crane price now.

Benefits of Single Girder Bridge Cranes

- Cost-Effective Solution: One of the standout advantages of single girder bridge cranes is their cost-effectiveness. This makes them an attractive option for manufacturers looking to enhance their material handling capabilities without exceeding budget constraints.

- Space-Saving Design: The single girder configuration translates to a space-saving design, making these cranes ideal for facilities where floor space optimization is a priority. Their compact structure allows for efficient use of available workspace.

Applications of Single Girder Bridge Cranes

- Lighter Machinery Components Handling: Single girder bridge cranes excel in handling lighter machinery components. Their design is particularly well-suited for transporting parts that don't require the load-bearing capacity of larger cranes.

- Assembly Lines with Moderate Load Requirements: These cranes find their niche in assembly lines that involve moderate load requirements. Their precision movement and adaptable load capacity make them valuable assets in ensuring seamless assembly processes.

In the realm of machinery manufacturing, where efficiency, cost-effectiveness, and precision are essential, single girder bridge cranes stand as a testament to innovation. Their ability to handle lighter loads while providing reliable and efficient material handling makes them a trusted choice for manufacturers seeking enhanced productivity.

In the upcoming sections of this series, we'll continue to unravel the world of bridge cranes, exploring double girder bridge cranes, top running and underhung bridge cranes, gantry cranes, and jib cranes. Each type brings a unique set of features and benefits to the table, catering to the diverse needs of machinery manufacturing. Stay tuned to expand your knowledge on the integral role these cranes play in shaping the industry's success.

Double Girder Bridge Cranes

Exploring Types of Bridge Cranes - Double Girder Bridge Cranes

In the dynamic realm of machinery manufacturing, where heavy loads and intricate assemblies take center stage, the emergence of double girder bridge cranes marks a significant stride in material handling innovation. This section of our series unveils the powerful features, compelling benefits, and real-world applications that position double girder bridge cranes as indispensable assets within the industry.

Features of Double Girder Bridge Cranes

Double girder bridge cranes are designed with a unique configuration that incorporates two beams for lifting and movement. This structural enhancement serves as a cornerstone for handling heavier loads and spanning longer distances. As a result, these cranes are adept at tackling the challenges posed by substantial machinery components and complex assembly processes.

Chinese style double girder hoist crane

Overhead electric winch crane is China traditional heavy duty double girder bridge crane equipped winch trolley,Robust & Sturdy, Affordable industrial overhead winch cranes.

Chinese style double girder open winch crane

5 ton- 63 ton double girder overhead bridge crane with rope hoist trolley / chain hoist trolley, competitive hoist trolley crane system, cheaper hoist trolley crane price, good electric bridge crane solution.

Chinese style double girder hoist crane

Overhead electric winch crane is China traditional heavy duty double girder bridge crane equipped winch trolley,Robust & Sturdy, Affordable industrial overhead winch cranes.

Chinese style double girder open winch crane

5 ton- 63 ton double girder overhead bridge crane with rope hoist trolley / chain hoist trolley, competitive hoist trolley crane system, cheaper hoist trolley crane price, good electric bridge crane solution.

European style double girder open winch crane

European standard double girder bridge crane with open winch trolley, a heavy duty winch crane up to 320 ton, wide specifications hook cranes for wide application. Get FEM / DIN open winch travelling bridge crane now!

European style double girder hoist trolley crane

Advanced double girder bridge crane based on European DIN/FEM Standard with 5 ton-80 ton electric wire rope hoist trolley for hoisting industrial materials - European advanced wire rope hoist cranes!

Ladle crane: 5 ton -74 ton steel mill ladle crane & 5 ton up 320 ton ladle crane

Ladle cranes for 5 ton -320 ton ladle or liquid metal lifting, heavy duty ladle crane for steel mill, foundry, furnace, and casting factory. Good priced ladle crane, charging crane, casting crane & foundry crane !

Electromagnetic cranes & Electromagnets

Electromagnetic bridge cranes with types of electromagnetic chucks & magnetic carrier beams for steel scraps, billet, slab,wire, coil, pipe, plate, etc., handling with efficiency and safety.

Rotary bridge crane with electro- magnet beam spreader

Magnetic crane is a double girder bridge crane with rotary crane design & electromagnet beam spreader, lifting long & larger steels, safe & efficient rotary bridge crane.

Grab crane- Overhead crane with crane grab bucket

5 ton 10 ton 16 ton 20 ton Grab Overhead Cranes with orange peeler grabs or clamshell grab buckets for scattered material handling in power station, steel mill, port, cement plant,storage & waste recycling station, etc

Benefits of Double Girder Bridge Cranes

- High Load Capacity: The defining feature of double girder bridge cranes is their ability to accommodate high load capacities. This attribute makes them an invaluable asset for industries dealing with substantial machinery and equipment.

- Versatility for Various Machinery Sizes: Double girder bridge cranes are renowned for their versatility. They can seamlessly handle a range of machinery sizes, from large components to intricate assemblies, making them adaptable to different production scenarios.

Applications of Double Girder Bridge Cranes

- Heavy Machinery Handling: Double girder bridge cranes come into their own when it comes to the handling of heavy machinery. Their robust design and high load capacity make them an optimal choice for moving large equipment and components.

- Large Component Assembly: The precision and strength of double girder bridge cranes make them indispensable in the assembly of large machinery components. Their ability to position parts accurately ensures efficient and error-free assembly processes.

As machinery manufacturing continually pushes the boundaries of innovation, double girder bridge cranes serve as a testament to the industry's commitment to excellence. Their capability to shoulder substantial loads while providing precise movement showcases their significance in enhancing productivity and safety.

Stay tuned as our exploration of bridge cranes delves deeper into the world of top running and underhung bridge cranes, gantry cranes, and jib cranes. With each crane type catering to specific needs, machinery manufacturers are equipped with a diverse toolkit to overcome challenges and seize opportunities.

Navigating Top Running Bridge Cranes - Efficient Material Handling in Machinery Manufacturing

In the dynamic landscape of machinery manufacturing, where every inch of space matters, top running bridge cranes emerge as masterful solutions for efficient material handling and streamlined operations. As we venture into the world of top running bridge cranes, we'll explore their distinctive features, benefits, and applications that contribute to their prominent role in the industry.

Features of Top Running Bridge Cranes

Top running bridge cranes are characterized by their unique design, which involves traveling on elevated runways installed atop the building structure. This ingenious approach not only maximizes the utilization of valuable floor space but also provides an ideal solution for larger manufacturing facilities seeking optimal material handling capabilities.

Single girder top running bridge cranes

Providing you excellent value for your application, single girder designs allow you to be cost effective without compromising performance. Over the lifetime of the crane, you will save on new support structures as it has reduced wheel loads. This allows you to add more lifting capabilities to your runway structure without upgrading.

European Standard Suspension Top Running Bridge Crane

Lifting capacity of Top Running Bridge Crane: 1ton,3 ton, 5 ton to 10 ton

Span ofTop Running Bridge Crane: 3-15 m

Lifting height of Top Running Bridge Crane: 3-100 m

Ask for Top Running Bridge Crane price now.

Suspension Top Running Bridge Crane Chinese type

Lifting Capacity of Top Running Bridge Crane: 0.5ton, 3 ton, 5 ton to 10 ton

Span of Top Running Bridge Crane: 3m to 31.5m

Working Class of Bridge Crane: A3 to A5

Ask for Top Running Bridge Crane price now.

FEM / DIN Top running Top Running Bridge Crane

Lifting Capacity of Top Running Bridge Crane: 3.2ton, 3 ton, 5 ton 10 ton ton 16ton

Span of Top Running Bridge Crane: 7.5m to 28.5m

Working Class of Bridge Crane: A5

Ask for Top Running Bridge Crane price now.

Chinese Style Top Running Top Running Bridge Crane

Lifting Capacity of Top Running Bridge Crane: 1ton, 3 ton, 5 ton,10 ton up to 20 ton

Span Length of Top Running Bridge Crane: 7.5m-28.5m

Working Class of Bridge Crane: A3, A4

Ask for Top Running Bridge Crane price now.

Explosion Proof Top Running Bridge Crane

Lifting Capacity of Single Girder Crane: 1ton, 3 ton, 5 ton,10 ton up to 20 ton

Span of Top Running Bridge Crane: 7.5m to 28.5m

Working Class of Bridge Crane: A3, A4

Ask for Top Running Bridge Crane price now.

Partial Hung Low Headroom Top Running Bridge Crane

Lifting Capacity of Top Running Bridge Crane: 1ton, 3 ton, 5 ton,10 ton up to32 ton

Span of Top Running Bridge Crane: 7.5m to 22.5m

Working Class of Bridge Crane: A3, A4

Ask for Top Running Bridge Crane price now.

Low headroom Hoist Top Running Bridge Crane

Lifting Capacity of Top Running Bridge Crane: 1ton, 3 ton, 5 ton,10 ton up to32 ton

Span of Top Running Bridge Crane: 7.5m to 22.5m

Working Class of Bridge Crane: A3, A4

Ask for Top Running Bridge Crane price now.

Ladle handling Top Running Bridge Crane

Lifting Capacity of Top Running Bridge Crane: 1ton, 3 ton, 5 ton, 10t

Lifting Height of Top Running Bridge Crane: 6~18m

Working Class of Bridge Crane: M5

Ask for Top Running Bridge Crane price now.

Double Girder Top Running Bridge Crane

Double girder cranes are utilized when a comprehensive lifting solution is required. They are designed for applications with load capacities often exceeding 25 tons. Because the hook goes between the beams, double girder cranes have a higher lift height than single girder cranes.

Chinese style double girder hoist crane

Overhead electric winch crane is China traditional heavy duty double girder top running bridge crane equipped winch trolley,Robust & Sturdy, Affordable industrial overhead winch cranes.

Chinese style double girder open winch crane

5 ton- 63 ton double girder overhead electric crane with rope hoist trolley / chain hoist trolley, competitive hoist trolley crane system, cheaper hoist trolley crane price, good electric bridge crane solution.

European style double girder open winch crane

European standard double girder top running bridge crane with open winch trolley, a heavy duty winch crane up to 320 ton, wide specifications hook cranes for wide application. Get FEM / DIN open winch travelling bridge crane now!

European style double girder hoist trolley crane

Advanced double girder top running bridge crane based on European DIN/FEM Standard with 5 ton-80 ton electric wire rope hoist trolley for hoisting industrial materials - European advanced wire rope hoist cranes!

Ladle crane: 5 ton -74 ton steel mill ladle crane & 5 ton up 320 ton ladle crane

Ladle cranes for 5 ton -320 ton ladle or liquid metal lifting, heavy duty ladle crane for steel mill, foundry, furnace, and casting factory. Good priced ladle crane, charging crane, casting crane & foundry crane !

Electromagnetic cranes & Electromagnets

Electromagnetic bridge cranes with types of electromagnetic chucks & magnetic carrier beams for steel scraps, billet, slab,wire, coil, pipe, plate, etc., handling with efficiency and safety.

Rotary bridge crane with electro- magnet beam spreader

Magnetic crane is a double girder top running bridge crane with rotary crane design & electromagnet beam spreader, lifting long & larger steels, safe & efficient rotary bridge crane.

Grab crane- Overhead crane with crane grab bucket

5 ton 10 ton 16 ton 20 ton Grab Bridge Cranes with orange peeler grabs or clamshell grab buckets for scattered material handling in power station, steel mill, port, cement plant,storage & waste recycling station, etc

Double girder top running bridge crane with double trolleys

Double trolley bridge cranes of (2.5+2.5)~(200+200) tons, double trolleys & double hooks for long & heavy lifting. Overhead double trolley cranes drawing & trolley crane pdf for you now.

Benefits of Top Running Bridge Cranes

- Efficient Use of Available Space: One of the standout advantages of top running bridge cranes is their ability to make the most of the available space. By utilizing the vertical dimension, these cranes allow manufacturers to optimize their floor layout for enhanced productivity.

- Ideal for Larger Manufacturing Facilities: Top running bridge cranes find their natural habitat in larger manufacturing facilities where expansive work areas demand a versatile and comprehensive material handling solution.

Applications of Top Running Bridge Cranes

- Material Handling Across a Wide Area: The elevated runways of top running bridge cranes empower them to cover a substantial area, making them perfect for efficiently transporting materials across a large workspace.

- Machinery Assembly in Spacious Facilities: Top running bridge cranes excel in the assembly of machinery components within spacious facilities. Their ability to maneuver heavy loads and provide precise positioning contributes to seamless assembly processes.

In the intricate dance of machinery manufacturing, where precision and space optimization are critical, top running bridge cranes shine as strategic assets. By capitalizing on vertical space and providing efficient material handling capabilities, these cranes offer manufacturers a solution that aligns perfectly with the demands of modern production environments.

As our journey through the realm of bridge cranes continues, we'll delve deeper into the realm of underhung bridge cranes, gantry cranes, and jib cranes. Each type adds a unique dimension to the machinery manufacturing landscape, catering to specific needs and opening up new avenues for innovation. Stay tuned for more insights into the tools that shape the future of manufacturing.

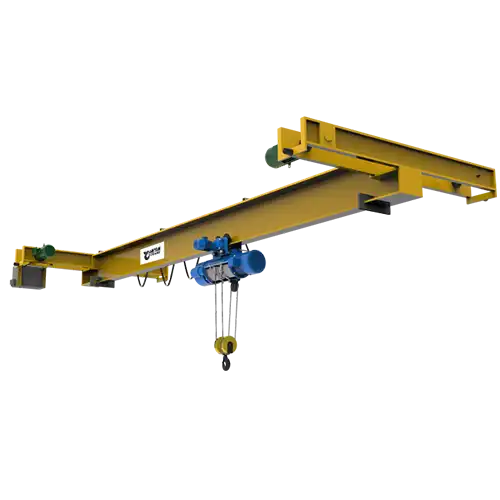

Underhung Bridge Cranes

Unveiling Underhung Bridge Cranes - Optimizing Space in Machinery Manufacturing

As the machinery manufacturing industry evolves, the need for innovative material handling solutions becomes increasingly crucial. Enter underhung bridge cranes, a versatile option designed to overcome space constraints and provide efficient material transport. In this segment, we'll delve into the defining features, advantages, and real-world applications that make underhung bridge cranes indispensable in compact and height-restricted manufacturing spaces.

Features of Underhung Bridge Cranes

Underhung bridge cranes exhibit a unique suspended design, attached from above to the building structure. This configuration allows them to navigate efficiently in spaces with limited headroom, providing a strategic solution for addressing challenges posed by height constraints.

Benefits of Underhung Bridge Cranes

- Space-Saving Design: The hallmark of underhung bridge cranes lies in their space-saving design. This makes them a valuable choice for manufacturers seeking to optimize their floor layout while maintaining efficient material handling capabilities.

- Suitable for Facilities with Height Constraints: Underhung bridge cranes shine in facilities where ceiling height is a limiting factor. Their suspended nature ensures that they can maneuver effectively without compromising on overhead clearance.

Applications of Underhung Bridge Cranes

- Compact Manufacturing Spaces: Underhung bridge cranes thrive in compact manufacturing environments, where space is a premium. Their ability to operate within confined areas makes them a go-to option for achieving efficient material handling.

- Machinery Handling in Areas with Low Ceiling Height: When dealing with low ceiling heights, underhung bridge cranes become an invaluable asset. They enable machinery handling in areas where traditional cranes might face restrictions.

As machinery manufacturing continues to evolve, the adaptability of underhung bridge cranes becomes increasingly relevant. Their ability to navigate within confined spaces and accommodate height limitations showcases their role as facilitators of seamless operations in unique production environments.

Stay tuned as our exploration of bridge cranes continues, delving into the realm of gantry cranes, jib cranes, and the diverse applications that each type caters to. In the intricate dance of manufacturing, these tools provide manufacturers with the agility and precision required to stay ahead in a dynamic industry.

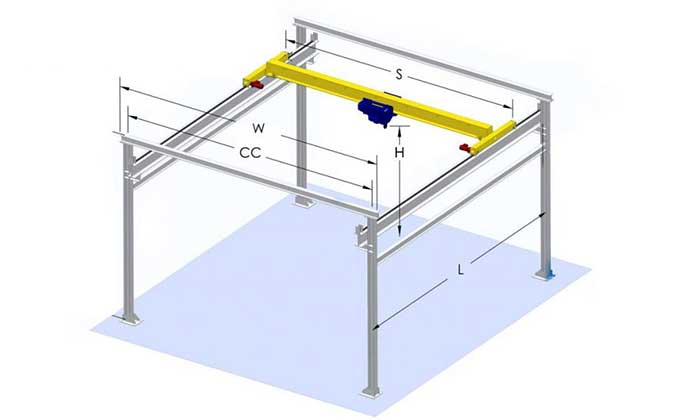

Gantry Cranes in Machinery Manufacturing

Gantry Cranes in Machinery Manufacturing - Powering Outdoor Handling and Shipbuilding

In the realm of machinery manufacturing, where precision meets durability, gantry cranes emerge as formidable allies. With the ability to seamlessly handle outdoor material transport and facilitate the assembly of massive structures, gantry cranes have carved a niche that underscores their significance. In this segment, we'll delve into the definition, features, and the wide range of applications that make gantry cranes indispensable in the machinery manufacturing landscape.

Definition and Features of Gantry Cranes

Gantry cranes, known for their imposing structures, are designed with legs that straddle the load. These cranes can move along a set of rails, covering a vast area for material handling and assembly. They stand as towering testaments to engineering prowess, capable of shouldering heavy loads and navigating outdoor environments with ease.

Benefits and Applications in Machinery Manufacturing

- Outdoor Machinery Handling: Gantry cranes are tailor-made for the challenges of outdoor environments. Their robust structure and versatility allow them to efficiently transport heavy machinery components across sprawling yards and construction sites.

- Shipbuilding and Heavy Equipment Assembly: In the realm of shipbuilding and the assembly of heavy equipment, gantry cranes are unsung heroes. They play a pivotal role in moving massive ship components and facilitating the assembly of towering structures, such as cranes used in port areas.

Gantry cranes offer a bridge between the manufacturing floor and the great outdoors. Their ability to withstand the elements while providing precise and controlled movement makes them essential for industries that demand reliability in any environment.

As we journey through the intricacies of bridge cranes, our exploration takes us further into the world of jib cranes and their specialized applications in machinery manufacturing. From confined spaces to precise positioning, these cranes continue to shape the future of efficient material handling. Stay tuned to discover more about the tools that drive innovation in manufacturing.

Jib Cranes in Machinery Manufacturing

Jib Cranes in Machinery Manufacturing - Precision in Confined Spaces

In the intricate dance of machinery manufacturing, where precision often hinges on the details, jib cranes emerge as nimble performers. These versatile cranes, designed for localized material handling, navigate the challenges of confined spaces with finesse. In this installment, we'll uncover the definition, varieties, and the array of applications that make jib cranes indispensable in machinery manufacturing.

Definition and Varieties of Jib Cranes

Jib cranes, characterized by their horizontal jib arm, are designed to provide precise movement within specific areas. These cranes come in various configurations, including wall-mounted, freestanding, and articulating jibs. Their compact structure allows for strategic positioning within workstations, optimizing material handling efficiency.

Advantages and Applications in Machinery Manufacturing

- Localized Material Handling within Workstations: Jib cranes excel in confined spaces, where their compact design shines. By enabling precise material movement within specific workstations, jib cranes facilitate seamless production processes.

- Assembly Line Loading and Unloading: In the intricate choreography of assembly lines, jib cranes play a vital role. They ensure efficient loading and unloading of components, reducing downtime and enhancing overall assembly line efficiency.

Jib cranes offer a glimpse into the future of machinery manufacturing, where precision is key, and space is a premium. Their ability to provide targeted material handling solutions within limited spaces positions them as valuable assets for manufacturers seeking to optimize workflows.

As our exploration of bridge cranes culminates, we've unraveled the diverse tapestry of single and double girder bridge cranes, top running and underhung bridge cranes, gantry cranes, and jib cranes. Each type adds a unique dimension to the machinery manufacturing landscape, contributing to seamless material handling, assembly, and production processes. With these tools in hand, manufacturers are poised to embrace efficiency, precision, and innovation in their journey to shape the future of manufacturing.

Bridge Cranes in Various Aspects of Machinery Manufacturing

In machinery manufacturing, various procedures require different types of overhead cranes to facilitate efficient material handling and assembly processes. Here's a breakdown of the typical overhead cranes used in each major procedure:

In this segment, we will witness how different types of bridge cranes seamlessly integrate into every stage of the manufacturing process, enhancing efficiency, precision, and safety.

A. Material Preparation and Machining:

In the initial stages of production, bridge cranes, whether single or double girder, take center stage. Their role involves moving raw materials to machining stations. With the ability to handle varying load capacities, these cranes facilitate the seamless transition of materials, setting the foundation for the manufacturing journey.

- Stacker Cranes: Used in warehouses and storage facilities to retrieve and store materials on racks or shelves. They are especially useful for managing inventory and optimizing storage space.

B. Assembly and Manufacturing:

Top running bridge cranes assume a pivotal role during assembly and manufacturing processes. Their precision movement and robust design allow them to position heavy components with accuracy. This ensures that intricate machinery assemblies come together seamlessly, minimizing errors and enhancing overall quality.

Material Preparation and Machining:

- Bridge Cranes: These are often used in machining areas to move heavy raw materials, components, and machinery parts to and from workstations.

- Jib Cranes: Can be used to transport smaller components within the machining area for tasks like loading and unloading CNC machines.

Welding and Fabrication:

- Bridge Cranes: Used to move large and heavy components to welding and fabrication stations. They provide precise positioning for accurate welding and assembly.

Assembly:

- Bridge Cranes: Used to lift and position heavy sub-assemblies and machinery parts onto the main assembly structure. Can also move completed assemblies to the testing area.

- Jib Cranes: Suitable for moving components within an assembly cell for precise placement and alignment.

Painting and Finishing:

- Bridge Cranes: Used to transport machinery components to painting and finishing areas. The cranes can position the parts for thorough and even coating.

C. Quality Control and Testing:

Underhung bridge cranes step in to transport finished machinery to testing areas. Their space-saving design and ability to navigate confined spaces make them the perfect choice for this crucial stage. By ensuring the safe and efficient transport of machinery, these cranes contribute to a comprehensive quality control process.

- Bridge Cranes: Used to move finished machinery to testing areas where they undergo quality control checks and performance testing.

D. Packaging and Shipping:

Gantry cranes, with their towering presence, are tasked with loading machinery onto trucks for transportation. Their ability to navigate outdoor environments and shoulder substantial loads comes to the forefront. These cranes play a key role in ensuring that machinery reaches its destination safely and securely.

- Gantry Cranes: Used in larger manufacturing facilities to lift and load completed machinery onto trucks for shipping.

- Bridge Cranes: Can also be used for loading machinery onto trucks or containers for transportation.

E. Maintenance and Repair:

When it's time for maintenance and repair, jib cranes prove their worth. Their compact design and precision movement allow them to lift and position machinery parts with ease. This aids maintenance teams in efficiently diagnosing and resolving issues, minimizing downtime.

- Jib Cranes: Often found in maintenance workshops for lifting and positioning machinery parts during repair and maintenance work.

From the initial stages of material preparation to the final steps of maintenance, bridge cranes embody versatility and adaptability in machinery manufacturing. By seamlessly integrating into every facet of the process, these cranes elevate efficiency, accuracy, and safety, ensuring that the machinery manufacturing industry continues to thrive on innovation and excellence.

As our journey through the world of bridge cranes concludes, we've uncovered their diverse applications, benefits, and pivotal roles across machinery manufacturing. Armed with this knowledge, manufacturers can make informed decisions and harness the power of these cranes to shape the future of their industry.

Applications of overhead crane used in and across machinery manufacturing sectors

Automobile Manufacturing:

- Assembly Line Handling: Bridge cranes move car body frames along the assembly line, positioning them for various stages of assembly, including adding engines, interiors, and other components.

- Typical Crane: Bridge Crane

- Features: High load capacity, long spans, precise positioning.

- Benefits: Efficient assembly line flow, accurate alignment, reduced manual labor.

- Functions: Lifting and moving car body frames along the assembly line, positioning them for various assembly stages.

Aerospace Manufacturing:

- Aircraft Component Handling: Bridge cranes transport large aircraft parts, such as wings and fuselage sections, to assembly areas, ensuring precise alignment during assembly.

- Typical Crane: Bridge Crane

- Features: High load capacity, long spans, precision controls.

- Benefits: Accurate alignment of aircraft components, improved safety.

- Functions: Moving large aircraft parts, such as wings and fuselage sections, to assembly areas.

Shipbuilding:

- Hull Assembly: Gantry cranes lift and position massive ship components, like hull sections and engines, for welding and assembly.

- Typical Crane: Bridge Crane

- Features: High load capacity, long spans, precision controls.

- Benefits: Accurate alignment of aircraft components, improved safety.

- Functions: Moving large aircraft parts, such as wings and fuselage sections, to assembly areas.

Heavy Machinery Manufacturing:

- Large Component Handling: Bridge cranes maneuver heavy machinery parts, such as excavator arms or bulldozer blades, for welding, painting, and assembly.

- Typical Crane: Bridge Crane

- Features: High load capacity, precise positioning, customizable attachments.

- Benefits: Efficient handling of heavy machinery parts, reduced assembly time.

- Functions: Moving and positioning large components for welding, painting, and assembly.

Steel Production:

- Material Handling: Bridge cranes move large steel coils or sheets to rolling mills and other processing stations for shaping and fabrication.

- Typical Crane: Bridge Crane

- Features: High load capacity, precise controls, reliability.

- Benefits: Efficient transport of heavy steel coils and sheets, streamlined production.

- Functions: Moving steel materials to rolling mills and processing stations.

Paper and Pulp Industry:

- Roll Handling: Jib cranes lift and move heavy paper rolls between storage areas, processing machines, and trucks for transportation.

- Typical Crane: Jib Crane

- Features: Space-saving, precise positioning, customizable attachments.

- Benefits: Efficient movement of heavy paper rolls, reduced risk of damage.

- Functions: Lifting and transporting paper rolls between storage, processing, and transport areas.

Energy and Power Generation:

- Turbine and Generator Assembly: Bridge cranes assist in assembling turbines and generators for power plants, ensuring precise alignment of components.

- Typical Crane: Bridge Crane

- Features: High load capacity, precision controls, safety features.

- Benefits: Accurate alignment of turbine components, efficient assembly.

- Functions: Lifting and positioning turbine and generator components during assembly.

Textile Manufacturing:

- Roll Handling: Jib cranes lift and move textile rolls to various stages of production, from spinning to weaving to packaging.

- Typical Crane: Jib Crane

- Features: Space-saving, precise positioning, customizable attachments.

- Benefits: Efficient movement of textile rolls, reduced manual handling.

- Functions: Transporting rolls between production stages, from spinning to weaving to packaging.

Food Processing Industry:

- Bulk Material Handling: Monorail cranes transport raw materials, ingredients, and packaged products within food processing plants.

- Typical Crane: Monorail Crane

- Features: Linear material movement, adaptability, customizable attachments.

- Benefits: Efficient material transport, improved hygiene.

- Functions: Moving raw materials, ingredients, and packaged products within food processing plants.

Construction Equipment Manufacturing:

- Heavy Equipment Assembly: Bridge cranes position components like bulldozer blades and excavator buckets during assembly.

- Typical Crane: Bridge Crane

- Features: High load capacity, precise positioning, customizable attachments.

- Benefits: Efficient assembly of heavy equipment, reduced assembly time.

- Functions: Positioning components like bulldozer blades and excavator buckets during assembly.

Medical Equipment Manufacturing:

- Medical Device Assembly: Jib cranes assist in assembling medical equipment, ensuring precise placement of sensitive components.

- Typical Crane: Jib Crane

- Features: Precise positioning, space-saving, customizable attachments.

- Benefits: Accurate placement of sensitive medical components, reduced risk of damage.

- Functions: Assisting in the assembly of medical equipment, ensuring precise alignment.

Mining Equipment Manufacturing:

- Large Equipment Handling: Gantry cranes move massive mining machinery components for assembly, maintenance, and transport.

- Typical Crane: Bridge Crane

- Features: High load capacity, precise positioning, reliability.

- Benefits: Efficient handling of massive mining machinery components, reduced assembly time.

- Functions: Moving and positioning heavy equipment components for assembly and maintenance.

Material Handling in Warehouses:

- Pallet and Container Handling: Bridge cranes in warehouses lift and transport pallets and containers, optimizing storage and order picking.

- Typical Crane: Bridge Crane

- Features: High load capacity, long spans, efficient material transport.

- Benefits: Optimized storage and order picking, reduced manual labor.

- Functions: Lifting and transporting pallets and containers within warehouses.

Automated Storage and Retrieval Systems:

- High-Density Storage: Stacker cranes retrieve and store items from racks and shelves in warehouses and distribution centers.

- Typical Crane: Stacker Crane

- Features: Vertical and horizontal movement, automated operation.

- Benefits: Maximized storage space, efficient retrieval and storage of items.

- Functions: Retrieving and storing items from racks and shelves in warehouses.

Plastic and Rubber Manufacturing:

- Mold Handling: Jib cranes assist in moving heavy molds to injection molding machines for plastic and rubber production.

- Typical Crane: Jib Crane

- Features: Precise positioning, customizable attachments.

- Benefits: Efficient movement of heavy molds, reduced risk of damage.

- Functions: Assisting in moving molds to injection molding machines for production.

These detailed applications demonstrate the versatility of overhead cranes in various industries and processes within machinery manufacturing. The ability to handle heavy loads, provide precise positioning, and optimize material movement makes overhead cranes indispensable tools in modern manufacturing environments.

Part 9: Making Informed Choices - Selecting Bridge Cranes for Machinery Manufacturing

In the intricate landscape of machinery manufacturing, the selection of the right bridge crane can spell the difference between streamlined operations and productivity bottlenecks. As we approach the end of our exploration, it's essential to understand the critical factors that guide the decision-making process. Let's dive into the considerations that play a pivotal role in choosing the perfect bridge crane.

Factors to Consider When Selecting Bridge Cranes for Machinery Manufacturing

- Load Capacity: The weight of the materials and components you'll be handling is a crucial factor. Different types of bridge cranes offer varying load capacities, ensuring that you choose a crane capable of safely lifting your loads.

- Span: The distance between the runways or supports directly affects the choice of bridge crane. Ensure that the crane you select can span the required distance without compromising stability.

- Facility Layout: The layout of your manufacturing facility dictates the type of bridge crane that will work best. Consider the available floor space, ceiling height, and the layout of workstations to determine the crane's size and configuration.

- Automation Needs: In the era of Industry 0, automation plays a pivotal role. Some bridge cranes can be integrated with automation systems for precise, hands-free operation. Evaluate your automation needs and choose a crane that aligns with your goals.

- Safety Features: Safety is paramount in manufacturing. Look for bridge cranes equipped with advanced safety features such as overload protection, emergency stop buttons, and collision avoidance systems.

All in all, from single and double girder cranes to top running and underhung cranes, gantry cranes, and jib cranes, each type offers a unique solution to the intricate challenges of material handling and assembly.

The versatility of bridge cranes shines in their ability to seamlessly integrate into various aspects of machinery manufacturing. From material preparation to quality control, packaging to maintenance, these cranes play pivotal roles at every step of the process, enhancing efficiency, precision, and safety.

As you navigate the landscape of machinery manufacturing, armed with the insights gained from this series, you're well-equipped to make informed decisions when selecting bridge cranes. Consider your specific needs, facility constraints, and production goals to choose the crane type that aligns perfectly with your requirements. With the right bridge crane by your side, you're poised to shape the future of manufacturing, one lift at a time.