Glass Handling Crane

Glass is one of the most versatile and frequently used materials which are widely used in the applications of lighting, optical, food and beverage, packaging, construction, and other many numerous applications in our daily life. Due to the diversity of glass applications, glass processing and handling may go through the procedures of polishing, bending, and drilling to grinding, laminating, cutting and others, etc.

Types of industrial cranes and hoists are widely used for reliable and efficient glass lifting and handling in various applications such as, in the glass processing plants and other related manufacturing plants and factories, such as PVC windows and doors manufacturing, glass whole sale, and other glass related applications, etc.

Complete Overhead Crane Solution for Glass Manufacturing

Material Handling in Glass Manufacturing

Glass production presents unique challenges due to the fragile and heavy nature of materials. Improper handling can lead to breakage, wasting valuable resources and time. Efficient material handling is crucial to ensure smooth production flow, reduce damage, and maintain consistent quality.

- Handling Fragile and Heavy Materials: Glass, whether in raw form, molten, or finished, is prone to damage. Careful handling is essential to avoid breakage.

- Efficient Handling Reduces Costs: Proper material handling ensures fewer delays and lower costs by minimizing waste and damage.

Overhead cranes play a pivotal role in reducing manual handling risks. They provide a reliable method to move raw materials, molten glass, and finished products without damage.

- Reducing Manual Handling Risks: Cranes automate lifting, reducing human error and accidents.

- Minimizing Breakage: Overhead cranes handle materials with precision, reducing the likelihood of breakage, especially with molten glass or fragile finished products.

Overhead Cranes in Streamlining Glass Manufacturing

Overhead cranes are essential for improving the efficiency and safety of glass manufacturing, playing a pivotal role across several stages of the production process. They ensure smooth operations from the handling of raw materials to the transportation of finished products.

Benefits Across Production Stages:

- Raw Material Handling: Overhead cranes move essential raw materials like silica, soda ash, and limestone to the production area with minimal effort.

- Molten Glass Handling: Cranes transport molten glass to molds and other critical areas, ensuring safe and efficient movement under high temperatures.

- Finished Product Handling: Cranes safely lift and move finished glass products to the cutting, packaging, and shipping areas, preventing damage and ensuring smooth transition through production.

By automating material handling, overhead cranes simplify production flows, ensuring a steady and continuous process.

Enhancing Safety and Productivity:

- Safety: Cranes reduce the need for manual handling, keeping workers away from hazardous tasks. This minimizes the risk of accidents and injuries, creating a safer working environment.

- Productivity: The automated movement of materials speeds up the production process, reducing downtime and increasing throughput. With cranes taking care of repetitive tasks, workers can focus on higher-value activities.

Overhead cranes are indispensable in glass manufacturing, offering significant improvements in both safety and productivity. By streamlining operations, they help create a more efficient and reliable production environment, contributing to overall success in the industry.

Requirements for Glass handling overhead cranes

The key requirements for a glass handling overhead crane are essential to ensure the safe and efficient handling of glass sheets. These requirements take into account the delicate and heavy nature of glass and aim to prevent damage during lifting, transporting, and placement. Here are the key requirements for a glass handling overhead crane:

- Smooth and Precise Movement: The crane's controls should allow for smooth and precise movement to prevent sudden jolts or shifts that could lead to glass breakage. Smooth acceleration and deceleration are crucial when handling delicate glass.

- Safety Features: Safety is paramount when handling glass. The crane should be equipped with safety features such as overload protection, emergency stop buttons, and safety interlocks to prevent accidents and ensure safe operations.

- Controlled Speeds: The crane should have variable speed control to allow for slow and controlled movements, especially when approaching the final position for glass placement.

- Anti-Sway Technology: To minimize swinging and swaying of the glass sheets during lifting and movement, some modern glass handling cranes come equipped with anti-sway technology. This feature helps stabilize the load and improves precision.

- Visibility and Lighting: Proper lighting and visibility are crucial when handling glass, especially in low-light conditions or indoor settings. Well-lit work areas reduce the risk of accidents and help operators handle the glass with greater care.

- Specialized Attachments: Glass handling overhead cranes should be equipped with specialized attachments, such as vacuum or suction cups. These attachments create a secure vacuum seal on the glass surface, providing a firm grip during lifting and movement.

- Remote Control Option: Some glass handling overhead cranes offer remote control options, allowing operators to have a better vantage point and improve precision during glass handling.

- Load Positioning Aids: Glass handling cranes may come equipped with load positioning aids, such as cameras or laser guides, to assist operators in accurately positioning the glass sheets.

By adhering to these key requirements, companies can ensure that their glass handling overhead cranes are well-suited for the task, minimize the risk of accidents or damage, and improve overall efficiency during glass transportation and installation processes.

Type of Industrial Cranes for Glass Lifting and Crane Handling

For the various glass applications, there are types of industrial hoists and cranes are designed and processed to meet the different applications and requirements for the indoor glass handling and glass lifting.

Overhead Bridge Travelling Cranes

The overhead travelling bridge cranes are usually adopted to handle the glass pallets with capacity up to 5 ton. With a vacuum lifter, the overhead travelling crane also can be adopted for the glass lifting and glass handling with a capacity from 500 kg to 2 tons in indoor workshops and warehouses, etc. Customized industrial overhead cranes are available for specific glass handling applications and glass lifting requirements.

Indoor overhead travelling crane for glass handling

Single Girder Bridge Cranes

Description: Single girder bridge cranes feature one overhead beam supported by two end trucks. These cranes are ideal for light to medium-duty lifting tasks within glass manufacturing plants.

Applications:

- Raw Material Handling: Transporting materials such as silica sand, soda ash, and limestone to the furnace.

- Finished Product Handling: Moving small glass containers or products to cutting and packaging stations.

- Forming Workshops: Handling smaller glass items or molds.

Hook Devices and Attachments:

- Grab Buckets: Used to handle bulk materials like sand, ensuring efficient transport without spillage.

- Magnetic Hooks: Often used for handling smaller metallic objects or glass molds that are magnetically compatible.

Benefits:

- Cost-effective for lighter loads (up to 20 tons).

- Simple design and easy maintenance.

- Suitable for tight spaces and shorter spans.

Double Girder Bridge Cranes

Description: Double girder bridge cranes provide increased lifting capacity and stability, making them ideal for heavier tasks.

Applications:

- Furnace/Glass Melting Workshop: Used for lifting molten glass and managing high heat conditions.

- Glass Forming Workshop: Moving large glass molds or finished glass products.

- Annealing and Cooling Workshops: Transporting delicate glass products from the forming area to cooling stations.

Hook Devices and Attachments:

- Heat-Resistant Hooks: These hooks are specially coated or constructed to handle extreme temperatures, ensuring safe lifting of molten glass.

- Electromagnetic Lifting Devices: Used for lifting heavy glass sheets or molds without direct contact, minimizing breakage risk.

Benefits:

- High lifting capacity (up to 50 tons or more) for heavy-duty tasks.

- Enhanced stability and safety features.

- Ideal for large production areas with long spans.

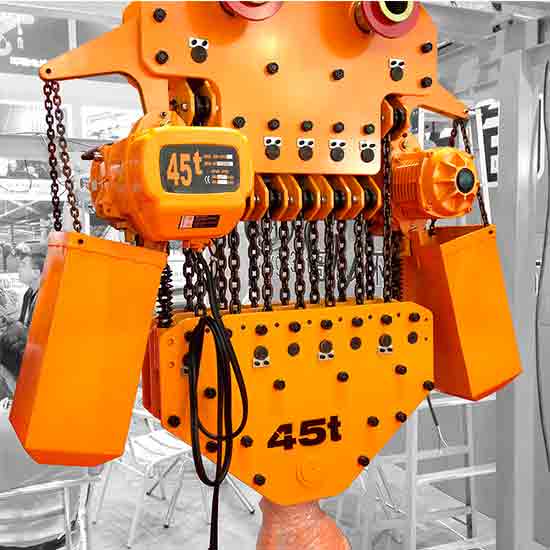

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.

Bridge Cranes with Vacuum Lifters:

Introduction: Bridge cranes are one of the most common types of overhead cranes used in the glass industry. When equipped with vacuum lifters, they become an excellent solution for handling glass sheets and products.

Main Features:

- Bridge cranes are overhead cranes with a horizontal beam (bridge) that runs along parallel runways. The bridge can move along the runways, and the trolley, which carries the vacuum lifter, moves along the bridge.

- Vacuum lifters are attached to the trolley, and they use vacuum suction cups to grip and lift glass sheets.

Benefits:

- Provides full coverage of the working area, allowing efficient movement and positioning of glass sheets.

- Vacuum lifters offer secure and damage-free handling of glass products.

- Suitable for various glass applications, including installation, manufacturing, and transportation.

Limitations:

- Load capacity depends on the bridge crane's specifications and the vacuum lifter's capabilities.

- May require a smooth and clean glass surface for optimal suction.

Typical Applications/Loads Handling:

- Installation of glass windows, facades, and doors in construction projects.

- Moving glass sheets in manufacturing and processing facilities.

- Handling glass panels for architectural and decorative purposes.

Articulating Glass Manipulators:

Introduction: Articulating glass manipulators, also known as knuckle boom manipulators, are versatile lifting devices specifically designed for handling glass sheets in confined spaces or areas with obstacles.

Main Features:

- Articulating manipulators consist of multiple interconnected segments, similar to the motion of a human arm.

- The segments allow the manipulator to reach around obstacles, making it ideal for handling glass in tight spaces.

Benefits:

- Increased flexibility and maneuverability in challenging environments.

- Precise positioning of glass sheets in confined or complex installation scenarios.

Limitations: Typically lower load capacity compared to bridge cranes.

Typical Applications/Loads Handling:

- Glass installation in areas with limited access or restricted spaces.

- Handling glass sheets in areas with obstacles or overhead obstructions.

Glass Furnace Charging Cranes:

Introduction: Glass furnace charging cranes are specialized overhead cranes designed for loading and unloading glass products to and from glass manufacturing furnaces.

Main Features:

- Heat-resistant design to withstand high temperatures near glass furnaces.

- Equipped with special lifting tools to handle hot glass products.

Benefits:

- Facilitates safe and efficient loading and unloading of glass products into/from glass furnaces.

- Minimizes the risk of thermal shocks or breakage due to high-temperature conditions.

Limitations: Limited to use near glass furnaces due to its specialized design.

Typical Applications/Loads Handling: Charging and discharging glass products in glass manufacturing furnaces.

These are some of the main types of glass handling overhead cranes and lifting devices used in the glass industry. Each type offers unique features and benefits, and the choice of the appropriate type depends on the specific needs and requirements of glass handling tasks. Proper training and adherence to safety protocols are crucial for safe and efficient glass handling operations.

Freestanding Bridge Crane

Free-standing bridge cranes are a type of self-supporting overhead crane commonly used in glass processing and manufacturing facilities.

Main Features:

- Self-supporting structure with floor-mounted columns.

- Horizontal bridge running along parallel runways.

- Various lifting mechanisms can be used, such as hoists, vacuum lifters, or manipulators.

Benefits:

- Efficient floor space utilization.

- Flexibility in installation and workstation arrangement.

- Relocation capability for changing production needs.

- Cost-effective alternative to building-supported bridge cranes.

Limitations:

- Lower load capacity compared to some building-supported cranes.

- Limited reach compared to larger bridge cranes.

Typical Applications:

- Glass processing: Handling glass sheets during cutting, shaping, and edging.

- Glass manufacturing: Moving glass products between production stages.

- Glass assembly: Final product staging before shipment or installation.

- Creating flexible workstations within manufacturing or processing facilities.

Jib Crane & Free Standing KBK cranes

The free standing kbk cranes is a type of glass handling cranes, with a porch like structure and equipped with a vacuum grip to lift the glass sheet vertically, or to rotate and turn the glass sheet to make glass lifting and handling much easier.With the feature of space-saving, stable operation, large working coverage, and labor saving, the kbk type glass handling cranes are widely used in the insulating glass line, lamination line, vertical CNC, tempering line, cutting line and others, etc.

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Light crane kbk system-kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

A jib-crane is a light duty glass handling crane which is consisted of a rotating jib arm, with a running hoists or a vacuum sucker lifter suspended on the vertical jib arm for the glass lifting and glass handling as required. Types of industrial jib cranes designs are available such as, free standing pillar jib crane, wall mounted and wall travelling jib cranes, etc. Jib cranes are one of the most economical light duty material handling cranes with the features of simple structure, easy manufacturing, installation and operation, low cost,and high safety and reliability, etc. The rotation jib cranes are suitable for lifting and handling insulating glass, tempered glass, solar photovoltaic glass and other types of glass, etc.

Semi -Gantry cranes/ Single Leg Gantry Cranes

The semi gantry crane is a cost-effective gantry crane with one supporting leg running on the ground rail and the other end supported on the build's supporting structure. The gantry cranes can be used for handling bundle of glass or for sheet glass handling with a glass suction lifer. Gantry cranes have a various crane designs and crane configurations, including full gantry crane, semi gantry crane, single girder gantry & double girder gantry and others for indoor and out applications. Customized gantry cranes can be used for your glass lifting and glass handling in your specific applications to improve your working efficiency, operation safety and working staff safety, etc.

Portable gantry crane & Economical mobile gantry-250 kg - 10 ton portable gantry cranes & mobile gantry cranes with adjustable / fixed gantry for small & light material handling.

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling.

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale.

Explosion-Proof Cranes

Description: Explosion-proof cranes are specially designed to operate in hazardous environments where flammable gases or chemicals are present. These cranes are equipped with components that minimize the risk of sparks or ignition.

Applications:

- Furnace/Glass Melting Workshop: Lifting molten glass in environments where flammable gases are present.

- Raw Material Preparation: Transporting volatile chemicals safely in batch houses.

- Chemical Handling Areas: Suitable for handling hazardous materials in glass manufacturing.

Hook Devices and Attachments:

- Explosion-Proof Hooks: Made from non-sparking materials, these hooks reduce the risk of ignition in volatile environments.

- Flameproof Lifting Devices: Lifting systems designed to operate safely in explosion-prone zones, reducing risks in hazardous workshops.

Benefits:

- Designed for safety in hazardous environments.

- Meets industry safety regulations for explosive environments.

- Reduces risks to workers and equipment.

Custom Cranes with Magnetic Lifting Systems

Description: Custom cranes with magnetic lifting systems are specialized for lifting molten glass or fragile glass items. These cranes are designed to minimize contact with materials, ensuring safe handling and reducing the risk of damage.

Applications:

- Furnace Workshop: Safely lifting molten glass using magnetic lifting systems to prevent contamination and breakage.

- Forming Workshop: Gently lifting large glass sheets or containers without direct contact.

- Annealing and Cooling Workshops: Transporting delicate glass products while minimizing stress and damage.

Hook Devices and Attachments:

- Electromagnetic Lifting Hooks: Magnetic hooks provide non-contact lifting, reducing the risk of damage to molten glass or fragile products.

- Suction Cups: Used to delicately handle glass sheets and molds without causing damage.

Benefits:

- Non-contact lifting reduces breakage risks and ensures safe handling.

- Ideal for handling molten or fragile glass products.

- Enhances operational efficiency by automating the lifting process.

Typical Overhead Crane Capacities and Applications in Glass Manufacturing Plants:

- 1 Ton to 5 Tons – Handling smaller glass sheets, molds, raw materials.

- 5 Ton to 10 Tons – Transporting glass molds, formed products, materials between stages.

- 10 Ton to 20 Tons – Handling larger glass sheets, molds, finished products in cutting and shaping.

- 20 Ton to 30 Tons – Heavy lifting for molten glass, large glass sheets, raw material transport.

- 30 Ton to 50 Tons – Handling larger glass panels, molten glass, large glass products in shipping.

- 50 Ton to 100 Tons – Transporting molten glass, large furnace operations, heavy-duty lifting for large glass sheets.

The right overhead crane, equipped with appropriate hook devices and attachments, plays a pivotal role in ensuring safety, efficiency, and productivity in glass manufacturing plants. Whether it's handling raw materials, molten glass, or delicate finished products, selecting the correct crane system and hook devices is crucial for optimizing operations. By understanding the specific needs of each production stage and applying the appropriate crane solutions, manufacturers can improve their workflow, reduce downtime, and ensure the safe handling of fragile and heavy glass materials throughout the production process.

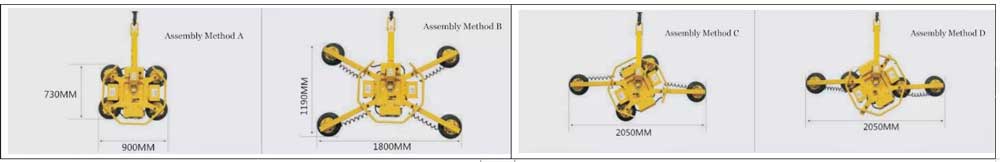

Vacuum Glass Lifter for Glass Lifting and Glass Handling

Vacuum glass lifter or suction glass lifer is a specialized lifting device for glass lifting and glass handling, widely used for sheet glass lifting and handling in the workshops and glass wall installation outdoor. The suction glass lifters are with the feature of no cracking at 20 degrees with a high temperature resistant of 90 degrees and with the features of high safety which can automatically lock the vacuum and hold the glass for 10-15 10-15 minute when the unexpected power off happens.

Glass vacuum lifters

Glass vacuum lifters are specialized lifting devices used for handling glass sheets and products. They utilize vacuum suction cups to grip and lift glass securely, making them a popular choice for various glass handling tasks.

Main Features:

- Independent lifting devices with vacuum suction cups.

- Different configurations to accommodate various glass sizes and shapes.

- Equipped with safety mechanisms to maintain grip even during power loss.

Benefits:

- Secure and damage-free handling of glass products.

- Versatile and can be used with different types of lifting equipment.

- Improved safety with redundant vacuum circuits and alarms for low vacuum levels.

Limitations:

- Load capacity may be limited by the size and strength of vacuum lifters.

- Requires a smooth and clean glass surface for optimal suction.

Typical Applications:

- Glass installation in construction projects.

- Moving glass sheets in manufacturing and processing facilities.

- Handling glass panels for architectural and decorative purposes.

- Transporting glass products during shipping and delivery.

With vacuum glass lifter, our material handling cranes not only can lift glass up down but also can help to rotate and turn the glass over to make the handling of glass much easier and efficient. At the same time, the using of vacuum glass lifter can help to lower risks of glass damages and personal injuries to enhance safety for your staffs and glass.

Key Stages in Glass Manufacturing and Crane Applications

Raw Material Handling (Batch House)

In the batch house, raw materials like silica sand, soda ash, and limestone are prepared and transported for the melting process. Proper handling of these materials is crucial to maintain smooth production and ensure the glass-making process starts on the right note.

Typical Materials:Silica sand, Soda ash, Limestone

Crane Solutions:

- Bridge Cranes (Single or Double Girder): Overhead bridge cranes, either single or double girder, are used to transport bulk raw materials across the facility. These cranes are known for their ability to move heavy materials with smooth, controlled movements.

- Magnetic Lifting Systems or Grab Buckets: For materials like granular silica or powder-based soda ash and limestone, cranes equipped with magnetic lifting systems or grab buckets make material handling more efficient. These systems prevent spillage and ensure quick and effective movement of materials.

Features of Bridge Cranes:

- Durability: Bridge cranes are built to handle the repetitive task of lifting heavy raw materials. They are engineered for long-term use under continuous heavy loads.

- Precision: These cranes offer advanced control systems that allow for the precise placement of materials. This is especially important when handling large quantities, ensuring minimal waste and smooth transitions in the production process.

- Safety Features: Safety is a priority in the batch house. Cranes are equipped with overload protection, limit switches, and emergency stop systems to ensure safe operation at all times.

Recommended Crane Capacity:

- 5 to 20 tons: This range is suitable for moving large volumes of raw materials while maintaining efficiency and safety. Cranes within this capacity range offer the right balance between strength and precision needed for material handling in the batch house.

Furnace/Glass Melting

The furnace or glass melting stage is where raw materials are heated to extremely high temperatures to create molten glass. This stage requires cranes that can manage both the extreme heat and the substantial weight of molten materials.

Handling Molten Glass:

- Molten glass, which can exceed temperatures of 1000°C, requires cranes that are specifically designed to handle such high heat. These cranes must operate effectively and safely in extremely hot environments without compromising performance.

Crane Solutions:

- Heavy-Duty Double Girder Cranes: These cranes are essential in the furnace area due to their increased lifting capacity and stability. The double girder design provides the necessary strength to handle heavy molten glass while ensuring smooth operations.

- Heat-Resistant Systems: Cranes in this environment are fitted with specialized heat-resistant components, including heat shields, high-temperature coatings, and materials that can withstand the intense heat produced by molten glass. These features help maintain crane performance over time, even under harsh conditions.

- Magnetic Lifting Systems: Magnetic lifting systems are highly effective for handling molten glass. These systems provide a non-contact lifting method, reducing the risk of glass damage while ensuring safe and efficient transport of molten glass.

Features of Bridge Cranes in Melting Furnaces:

- High Temperature Resistance: Specialized materials and coatings are used to ensure the crane can withstand extreme temperatures without degrading. This helps the crane maintain performance and longevity in high-heat environments.

- Powerful Lifting Capacity: These cranes are built to handle large loads, often over 20 tons, making them ideal for transporting molten glass and heavy equipment in the furnace area.

- Stability and Control: Advanced stability systems ensure precise lifting control. This is essential in molten glass handling, where maintaining the integrity of the material is crucial. These systems help ensure that the molten glass remains undisturbed during movement.

Recommended Crane Capacity:

- 20 to 50 tons: This capacity is required to safely handle the substantial weight of molten glass and the related equipment used in the furnace. Cranes within this range provide the necessary strength and reliability to manage the extreme demands of the glass melting process.

Glass Forming

Once the molten glass is shaped into molds or formed into final products, cranes are needed to move these delicate items. Precision is key during this stage to avoid breakage and ensure the product's integrity.

Handling Molds and Formed Glass Products:Molds and finished glass products are fragile, and careful handling is necessary to prevent damage during the transfer from one area to another.

Crane Solutions:

- Overhead Cranes with Precision Lifting Systems: These cranes, often equipped with suction cups or other advanced lifting devices, are used to handle delicate molds and glass products without causing damage.

- Suction Cup Lifting Systems: Designed to handle glass sheets or containers gently, these cranes ensure safe and damage-free lifting.

- Precision Control Systems: Overhead cranes are equipped with advanced control systems that allow for smooth and controlled movements, reducing the risk of mishaps during the handling of fragile materials.

Features of Bridge Cranes in Glass Forming:

- Precision Handling: Specialized lifting gear like suction cups or custom attachments allows for delicate handling of glass.

- Flexible Movement: These cranes are designed to operate in tight spaces and can move in multiple directions, allowing for quick and efficient transportation of glass products.

- Safety Features: Anti-collision systems and precise load monitoring enhance the safety of handling fragile glass products.

Recommended Crane Capacity:10 to 30 tons – Sufficient to safely transport glass molds and products without risking breakage during handling.

Annealing Lehr (Cooling and Hardening)

In the annealing process, glass is gradually cooled in a controlled environment to relieve internal stresses. Overhead cranes are essential during this phase to move the glass without causing breakage or damage due to its fragile state.

Handling Glass During Cooling:Cranes carefully transfer glass products from the furnace to the annealing lehr, ensuring the glass is not subjected to shock or jarring movements that could cause cracks or breaks.

Crane Solutions:Single Girder Cranes with Suction Cups or Grippers: These cranes are equipped with suction cups or grippers designed for delicate handling. The soft grip prevents the glass from being damaged while also ensuring a secure hold for transport.

Features of Bridge Cranes in Annealing Lehr:

- Gentle Lifting Mechanisms: Suction cups or grippers lift the glass gently and securely, minimizing any risk of damage.

- Controlled Speed: The cranes are designed with speed control features to ensure smooth and gradual movements, preventing sudden jolts or impacts.

- Precision: Accurate positioning is vital to avoid hitting or misplacing delicate glass products during the cooling phase.

Recommended Crane Capacity:5 to 20 tons – Sufficient to handle the weight of glass products without compromising the precision and gentleness required for this phase.

Cutting, Shaping, and Surface Treatment

Once the glass has cooled, it undergoes various processes such as cutting, shaping, and surface finishing. Overhead cranes play a significant role in transporting glass sheets between different processing stations.

Handling Large Glass Sheets:During these processes, cranes handle large and sometimes awkwardly shaped glass sheets, moving them from one station to another for cutting, polishing, or coating.

Crane Solutions:Cranes with Suction Cup Systems: These cranes are equipped with suction cups that hold the glass securely while minimizing any damage during cutting, shaping, or polishing.

Features of Bridge Cranes in Cutting and Shaping:

- Customized Lifting Attachments: The cranes are equipped with specialized attachments, such as custom suction cups, for handling various glass shapes and sizes.

- Flexible Movement: The cranes' ability to operate in tight spaces and move the glass precisely through the production area ensures smooth processing.

- Safe Transport: Cranes maintain stable transport of large glass sheets, ensuring they remain undamaged during the shaping or polishing process.

Recommended Crane Capacity:5 to 15 tons – Ideal for handling medium to large glass sheets efficiently without overloading the crane or risking damage.

Quality Control and Testing

In the quality control and testing stage, glass products are inspected for defects such as cracks or uneven surfaces. Overhead cranes are essential for transporting the glass to inspection stations for detailed examination.

Handling Glass for Inspection:Cranes move glass items carefully to quality control areas, ensuring they are not subjected to unnecessary handling that could impact their integrity or accuracy of inspection.

Crane Solutions:Light-Duty Cranes with Precision Handling Systems: These cranes are equipped with precision lifting systems to delicately move glass to inspection stations. The systems provide accurate positioning, ensuring that glass products are not damaged during transport.

Features of Bridge Cranes in Quality Control:

- Sensitive Handling: The cranes provide smooth and controlled movements, ensuring that the glass does not shift or get damaged.

- Precision Systems: These systems allow for fine-tuned control, ensuring that products are accurately placed for inspection without causing disruption to the process.

Recommended Crane Capacity:5 to 10 tons – Sufficient for handling glass with a focus on precision and avoiding any risk of breakage during inspection.

Packaging and Shipping

After passing quality control, glass products are moved to the packaging and shipping areas. Cranes are essential for transporting finished products to storage areas or loading docks.

- Handling Finished Products:The final glass products are fragile and often large, requiring careful handling during the final stages of packaging and shipping. Cranes are used to load and unload these products for storage or delivery.

Crane Solutions:Cranes with Suction Cup Lifting Systems: These cranes are equipped with suction cup systems to safely lift and move delicate glass products. The cups ensure that the glass is handled gently while securing it for transport.

Features of Bridge Cranes in Packaging and Shipping:

- Gentle Handling: Suction cup systems ensure that finished glass products are lifted gently, reducing the chance of cracks or chips.

- Secure Grip: The crane's lifting mechanisms provide a secure grip, ensuring that the glass is safely transported to the packaging or shipping area.

- Speed and Efficiency: The cranes are designed to move products quickly and efficiently, increasing throughput while maintaining product safety.

Recommended Crane Capacity:10 to 30 tons – Ideal for handling large quantities of finished glass products and ensuring safe and efficient transport to the final stages of production.

The Benefits of Complete Overhead Crane Solutions for Your Production Line

Cost-Effectiveness

- Integrated Systems for Multiple Stages: One crane system can handle several stages of production, eliminating the need for additional equipment. This reduces complexity and saves on costs.

- Long-Term Savings: Efficient crane systems lower downtime, maintenance, and energy costs. This results in significant savings over time and a better return on investment.

Increased Safety

- Reduced Manual Handling Risks: Overhead cranes take over heavy lifting, reducing the risk of worker injuries. This makes the workplace safer by minimizing physical strain and the chances of accidents.

Improved Productivity

- Streamlined Operations: Automated cranes move materials quickly and efficiently, speeding up the production process. This smooths out production flow, boosts throughput, and helps meet deadlines with higher output.

Customization and Flexibility

- Tailored Crane Systems: Cranes can be customized for specific needs at each stage of production. Whether handling fragile materials or molten glass, cranes can be designed to fit every part of the process.

- Scalability: Cranes can be upgraded to handle increased production needs. As your business grows, crane systems can be expanded or modified to meet new demands.

Glass Manufacturing Plant Layout and Overhead Crane Requirements

General Layout of a Glass Manufacturing Plant

- Raw Material Handling Section: Bridge cranes for bulk material handling.

- Furnace/Glass Melting Section: Heavy-duty cranes with heat-resistant systems for molten glass handling.

- Forming and Shaping Section: Overhead cranes with suction cups for handling molds and glass products.

- Annealing Lehr Section: Single girder cranes with suction cups for delicate glass handling.

- Cutting and Shaping Section: Light-duty cranes for precision glass transportation.

- Tempering and Coating Section: Medium-capacity cranes for specialty glass handling.

- Quality Control and Inspection: Light-duty cranes for small glass sheet handling.

- Packaging and Shipping Section: Heavy-duty cranes with suction cup lifting systems for finished glass.

Production Line Layouts Based on Glass Type

The production lines for different glass products often vary significantly, as the requirements for handling, processing, and finishing can differ based on the type of glass being produced. Each type of glass—whether it's container glass, flat glass, specialty glass, or glassware—requires tailored production processes, specialized equipment, and material handling systems.

Container Glass (e.g., Bottles, Jars)

Production Line Features:

- Forming and Shaping: The production of container glass involves molding molten glass into various shapes, such as bottles, jars, or vials. The process requires high-speed forming machines.

- Handling Requirements:Cranes are used to move molds, molds with molten glass, and large quantities of finished products.Handling delicate glass bottles or jars with suction cups or automated systems.

- Material Handling:High-Volume and Continuous Production: The production line typically requires quick turnaround times for large batches, so cranes and conveyors are crucial for rapid movement.

Typical Cranes:

- Single or Double Girder Overhead Cranes: Used for moving large glass batches, molds, and pallets of finished containers.

- Suction Cup or Gripper Systems: For safely handling finished bottles or jars.

Flat Glass (e.g., Windows, Mirrors, Architectural Glass)

Production Line Features:

- Cutting and Shaping: Molten glass is formed into large sheets, which are then cut to size. The glass may be tempered or laminated for durability and safety.

- Handling Requirements:Large glass sheets, often fragile and requiring careful handling, are moved through the production line.

- Material Handling:Glass sheets are lifted and transferred to various workstations for cutting, shaping, and finishing. Overhead cranes are often used to move large, flat glass products to different sections of the line.

Typical Cranes:

- Double Girder Overhead Cranes: With high lifting capacities, these cranes are essential for handling large, heavy sheets of glass.

- Suction Cup Systems: For lifting large sheets and glass panels with minimal risk of breakage.

Specialty Glass (e.g., Tempered, Laminated, Bulletproof, Glass for Electronics)

Production Line Features:

- Precision Processing: Specialty glass often undergoes more intricate processes, such as tempering, laminating, or coating, to achieve specific properties (e.g., increased strength or clarity).

- Handling Requirements:Glass may need to be handled in specific ways to preserve its properties, such as avoiding sharp bends or unnecessary handling during cooling.Smaller and more precise products often need customized handling equipment.

- Material Handling:Specialized lifting devices such as magnet cranes, suction cups, or robotic arms may be used for delicate, high-precision handling.

Typical Cranes:

- Single Girder Cranes with Suction Cups: These are often used to handle delicate or smaller products.

- Custom Lifting Devices: Depending on the product, custom lifting solutions may be used to maintain the integrity of specialty glass.

Glassware (e.g., Drinking Glasses, Decorative Items)

Production Line Features:

- Molding and Blowing: Glassware is typically formed using molding or blowing techniques, which require precision in handling hot and delicate glass.

- Handling Requirements:As these items are fragile and often have intricate shapes, handling must be done carefully.After molding or blowing, the glassware is usually placed in annealing ovens, then cooled and inspected for defects.

- Material Handling:Cranes may be used for moving batches of molds, finished glassware, or items undergoing quality inspection.

Typical Cranes:

- Single Girder Cranes: Smaller cranes are suitable for lifting molds, glassware in batches, and moving finished items.

- Suction Cups and Grippers: These systems are used for moving delicate, finished glassware without causing damage.

Automotive and Architectural Glass (e.g., Windshields, Windows, Glass Panels)

Production Line Features:

- Cutting and Shaping: These glass products often undergo highly specialized processes such as bending, tempering, or coating to meet specific regulatory and design requirements.

- Handling Requirements:Large, flat sheets of glass must be carefully transported through various processing stages.Products must be handled gently to avoid scratches or breakage, particularly in automotive glass.

- Material Handling:Overhead cranes are used to move large, heavy glass sheets from one part of the production line to another.

Typical Cranes:

- Double Girder Overhead Cranes: These cranes are used to handle the heavy glass sheets typical in automotive or architectural glass production.

- Suction Cups and Magnetic Lifting: These systems are especially useful for delicate or large glass panels, ensuring they are moved safely without causing any surface damage.

Key Differences in Production Lines

- Speed and Scale: Container glass and flat glass production lines are often faster-paced and require high-volume handling systems, while specialty glass and glassware production lines may be slower and require more delicate handling.

- Customization of Handling Equipment: The production of specialty glass and glassware often requires more customized lifting solutions, such as specialized suction cups, robotic arms, or conveyors designed for delicate items.

- Crane Capacity: The required crane capacity varies widely across different glass products. For example, container glass or flat glass production may require cranes with capacities between 10 to 50 tons, while glassware production may require smaller cranes with capacities of 5 to 15 tons.

The production lines for different types of glass products are indeed different, as each type of glass product has unique production processes, handling requirements, and material needs. Overhead cranes play an essential role in all these processes, but their design and capacity must be tailored to the specific type of glass being produced. For manufacturers, understanding these differences helps ensure they invest in the right crane systems that meet their needs for both safety and efficiency.

Industrial Glass Handling Cranes for Your Applications

For the various glass applications, we can offer types of industrial hoists and glass handling cranes which are designed and processed to meet the different applications and requirements for glass handling and glass lifting. Contact us to get your tailored glass handling cranes for your specific application to improve working efficiency and enhance safety for glass and for all your staffs.

Applications of Glass Handling Cranes:

Glass Manufacturing:

- Glass handling cranes play a vital role in the manufacturing of glass products. They are extensively used to move raw materials such as glass sheets, sand, and other components within the production facility. Additionally, these cranes facilitate the transportation of glass products between different stages of the manufacturing process. They also handle glass molds and tools used in shaping and forming glass during production. Furthermore, glass handling cranes are responsible for the loading and unloading of glass products onto conveyors or storage areas.

- Typical industrial Overhead Cranes Used: Bridge Cranes, Free-Standing Bridge Cranes. Glass handling bridge cranes, including traditional bridge cranes and free-standing bridge cranes, are commonly used for material handling in glass manufacturing. They facilitate the movement of raw materials, glass sheets, molds, and tools within the production facility.

Glass Processing:

- In the glass processing phase, cranes designed for glass handling are indispensable. They assist in various critical tasks, including cutting, edging, shaping, and tempering glass sheets. These cranes enable the movement of glass sheets to different workstations, ensuring smooth and efficient processing operations. Moreover, glass handling cranes are involved in handling glass products during quality control inspections, ensuring that the final products meet the required standards.

- Typical Industrial Overhead Cranes Used: Bridge Cranes, Jib Cranes. Bridge cranes and jib cranes are essential for glass processing operations. Bridge cranes assist in transporting glass sheets during cutting, edging, shaping, and tempering processes. Jib cranes provide rotational movement and are used to move glass sheets to different workstations during processing.

Glass Installation:

- One of the primary applications of glass handling cranes is in the installation of glass products in various architectural and construction projects. They are extensively used to install glass windows, doors, and facades with precision and safety. These cranes are also employed for positioning glass panels for intricate architectural features and artistic installations, providing accurate alignment and aesthetics.

- Typical Industrial Overhead Cranes Used: Bridge Cranes, Vacuum Glass Lifting Cranes. Bridge cranes, equipped with vacuum glass lifting systems, are indispensable for installing glass windows, doors, and facades in construction projects. The combination of bridge cranes with vacuum lifters ensures precise and safe glass placement during installation.

Glass Transportation:

- Glass handling cranes play a significant role in the transportation of glass products within and outside the production facility. They are instrumental in loading and unloading glass products onto trucks or containers for safe transportation to construction sites or customers. These cranes are particularly useful for handling large and heavy glass sheets between storage areas and processing facilities. Additionally, they ensure efficient and safe handling of glass products during shipment to distribution centers or retail outlets.

- Typical Overhead Cranes Used: Bridge Cranes, Vacuum Glass Lifting Cranes

Bridge cranes, along with vacuum glass lifting systems, are used for loading and unloading glass products onto trucks or containers for transportation to construction sites or customers. They ensure safe and efficient handling during glass transportation.

Glass Recycling:

- Glass handling cranes are involved in the recycling of glass materials. They assist in the movement of glass cullet (crushed glass) for recycling processes. Moreover, these cranes are responsible for transporting recycled glass materials for reuse, contributing to sustainable glass manufacturing practices.

- Typical Industrial Overhead Cranes Used: Bridge Cranes. Bridge cranes are utilized in glass recycling processes to handle glass cullet (crushed glass). They assist in the movement and transportation of recycled glass materials for reuse.

Glassware Manufacturing:

- In the glassware manufacturing industry, cranes designed for glass handling are used to streamline production processes. They are employed in handling glass bottles, containers, and glassware during various stages of manufacturing. Additionally, these cranes play a significant role in moving glass products for packaging and storage.

- Typical Industrial Overhead Cranes Used: Bridge Cranes. Bridge cranes are commonly used in glassware manufacturing facilities for material handling and movement of glass bottles, containers, and glassware during various stages of production.

Automotive Glass Production:

- Glass handling cranes are crucial in the automotive industry, particularly in the production of automotive glass products. They assist in the safe and efficient handling of automotive glass, including windshields, side windows, and rear windows, during manufacturing and assembly processes.

- Typical Industrial Overhead Cranes Used: Bridge Cranes, Glass Laminating Cranes. Bridge cranes and specialized glass laminating cranes are essential in the automotive industry for handling automotive glass products, including windshields, side windows, and rear windows, during manufacturing and assembly processes.

Solar Panel Manufacturing:

- In the solar energy sector, glass handling cranes are used to transport glass sheets used in solar panel production. They play a vital role in assisting the assembly and handling of solar panels, contributing to the renewable energy industry.

- Typical Industrial Overhead Cranes Used: Bridge Cranes. Bridge cranes play a significant role in the solar energy sector by transporting glass sheets used in solar panel production. They also assist in the assembly and handling of solar panels.

Glass Repair and Replacement:

- For glass repair and replacement tasks, glass handling cranes are instrumental in lifting and replacing damaged or broken glass panels in buildings and vehicles. These cranes ensure precise positioning and safe handling during repair and replacement operations.

- Typical Industrial Overhead Cranes Used: Bridge Cranes, Vacuum Glass Lifting Cranes. Bridge cranes, along with vacuum glass lifting systems, are employed for glass repair and replacement tasks. They provide the necessary lifting capabilities to lift and replace damaged or broken glass panels in buildings and vehicles.

Art and Sculpture Installations:

- Glass handling cranes are also utilized in art and sculpture installations. They provide the necessary lifting capabilities to install artistic glass pieces and sculptures with accuracy and care.

- Typical Industrial Overhead Cranes Used: Articulating Glass Manipulator Bridge Cranes.Articulating glass manipulator bridge cranes are used in art and sculpture installations, providing precise glass handling and installation of artistic glass pieces and sculptures.

In conclusion, glass handling cranes find diverse applications in various industries, including glass manufacturing, processing, installation, transportation, recycling, automotive, solar energy, glassware manufacturing, and more. They offer safe, efficient, and reliable solutions for handling glass sheets and products, contributing to increased productivity and the delivery of high-quality glass products in different sectors.

In conclusion, various types of overhead cranes, including bridge cranes, free-standing bridge cranes, jib cranes, vacuum glass lifting cranes, glass laminating cranes, and articulating glass manipulator bridge cranes, are employed in different glass handling applications across various industries. These cranes offer safe, efficient, and reliable solutions for handling glass sheets and products, contributing to increased productivity and the delivery of high-quality glass products in different sectors.

Conclusion

Why a Complete Overhead Crane Solution is Essential for Your Glass Manufacturing Plant

- Cost-Effectiveness, Safety, and Productivity: A complete overhead crane solution is key to optimizing your glass manufacturing operations. Overhead cranes streamline material handling throughout all production stages, significantly reducing the need for manual labor and minimizing the risk of accidents. By improving handling efficiency, these systems help manufacturers save on labor costs, reduce downtime, and boost overall productivity.

- Long-Term Benefits: The right crane system not only ensures safe and efficient operation but also provides long-term savings through lower maintenance costs and fewer production interruptions. Over time, a customized crane solution becomes an integral part of your production line, enabling continuous and efficient operations.

Getting Started with Your Custom Overhead Crane Solution

- Steps for Implementation: The first step in implementing an overhead crane system is a consultation with experienced professionals who can assess your plant’s specific needs. This ensures the crane system is tailored to your production line’s capacity, lifting requirements, and unique material handling challenges.

- Contact Information: Reach out today for a personalized crane solution. Our experts are ready to guide you through the design, selection, and implementation of a crane system that will enhance your facility’s efficiency and safety.

Crane Selection Guide for Glass Manufacturing Plant

Bridge Cranes (Single or Double Girder) - 5 to 20 tons

Application: Raw Material Handling (Batch House)

Use: Transporting bulk materials.

Heavy-Duty Double Girder Cranes - 20 to 50 tons

Application: Furnace/Glass Melting

Use: Handling molten glass.

Overhead Cranes with Vacuum Lifters - 10 to 30 tons

Application: Glass Forming

Use: Moving molds and formed glass.

Single Girder Cranes with Vacuum Lifters - 5 to 20 tons

Application: Annealing Lehr

Use: Transporting glass during cooling.

Light-Duty Cranes with Vacuum Lifting Systems - 5 to 15 tons

Application: Cutting, Shaping, and Surface Treatment

Use: Moving glass for processing.

Light-Duty Cranes with Precision Handling - 5 to 10 tons

Application: Quality Control and Testing

Use: Transporting glass for inspection.

Heavy-Duty Cranes with Vacuum Lifting Systems - 10 to 30 tons

Application: Packaging and Shipping

Use: Moving finished glass products.

Investing in a complete overhead crane system is a smart decision for glass manufacturers looking to improve productivity, reduce costs, and enhance safety. By selecting a customized solution, you can ensure smooth material handling across all stages of production, minimize downtime, and achieve long-term operational efficiency.

Cranes for Glass Related Industrial Sectors

Glass is a versatile material used in various industries and applications due to its transparency, durability, and aesthetic appeal. Some common uses of glass include:

Let's explore the types of cranes and their typical applications used in the glass-related industry sectors mentioned:

Construction and Architecture:

- Cranes: Bridge Cranes, Free-Standing Bridge Cranes, Wall-Mounted Jib Cranes

- Typical Applications: Glass installation for windows, doors, facades, skylights, and partitions during construction projects.

Automotive:

- Cranes: Glass Laminating Cranes

- Typical Applications: Handling and assembling automotive glass products, including windshields, side windows, and rear windows.

Electronics:

- Cranes: Vacuum Glass Lifting Cranes, Articulating Glass Manipulator Bridge Cranes

- Typical Applications: Precise handling of glass sheets for display screens in smartphones, TVs, and computers during manufacturing and assembly.

Household:

- Cranes: Vacuum Glass Lifters

- Typical Applications: Handling glass bottles, containers, glassware, and mirrors during production and packaging in household items manufacturing.

Furniture:

- Cranes: Bridge Cranes, Jib Cranes

- Typical Applications: Moving glass sheets for tabletops, shelves, and decorative pieces during furniture manufacturing.

Lighting:

- Cranes: Vacuum Glass Lifting Cranes

- Typical Applications: Handling glass components for light fixtures, lamps, and bulbs during production.

Solar Panels:

- Cranes: Bridge Cranes, Vacuum Glass Lifting Cranes

- Typical Applications: Transportation and positioning of glass sheets used as protective covers for solar panels during manufacturing.

Laboratory Equipment:

- Cranes: Bridge Cranes

- Typical Applications: Handling and transporting glassware in laboratories.

Art and Decorations:

- Cranes: Articulating Glass Manipulator Bridge Cranes

- Typical Applications: Precise installation of stained glass and artistic glass pieces for decorative purposes.

In the glass-related industry sectors mentioned above, various types of cranes are utilized for different glass handling applications. Bridge cranes and free-standing bridge cranes are commonly used for material handling and glass transportation in manufacturing processes. Vacuum glass lifting cranes are employed for precise and damage-free glass handling in various industries. Articulating glass manipulator bridge cranes are used for intricate glass installation tasks in art and decorations. Proper selection and utilization of the appropriate crane type ensure safe and efficient handling of glass sheets and products, contributing to improved productivity and the delivery of high-quality glass products.