Overhead Travelling Crane Overview- Right Travelling Crane for You

What is an electric overhead travelling crane?

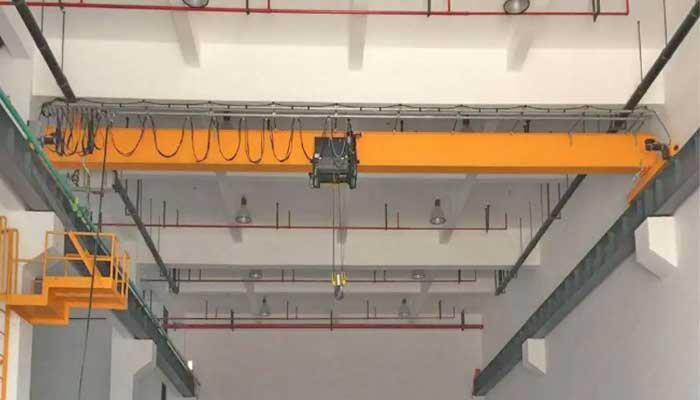

Overhead travelling cranes are used to lift and move loads from one location to another in an efficient and safe motion. Ususally, the overhead travelling cranes are consisted of one/ two crane girder bridge, two crane runways, and crane hoist trolley which is suspened on the under flange of crane bridge or rides on along the runways on the bridge for loads horizontally and vertically.

Overhead Crane Benifits & Applications- Part 1 of Series of What's an Overhead Crane?

Overview of overhead travelling crane

- Concept of Overhead Travelling Cranes :This crane is Horizontal placed in workshop, storage, on top of steel support. It used to lift object or machine.

- Working Application of Overhead Travelling Cranes :Workshop, factory, warehouse, store yard for loads loading& unloading

- Loading capacity of Overhead Travelling Cranes :Rated capacity from 1 ton to 550 ton.

- Advantage of Overhead Travelling Cranes : High safety and efficiency which can be customized with with various crane configurations and designs with Light duty, Medium duty and Heavy duty.

- Disadvantage of Overhead Travelling Cranes Supporting structure is needed by overhead travelling crane in working area, cost is higher, working area is limited.

- Structure of Overhead Travelling Cranes :Overhead cranes are travelling on rail which are placed on concrete or steel structure.

Main types of Overhead Travelling cranes:

- Single girder overhead travelling crane: A single crane girder or crane beam that runs above or below the runway/end carriages /end trucks.

- Double girder overhead travelling crane: Consists of 2 bridge beams or girders on top of the crane runway/end trucks/ end carriages.

- Top running overhead travelling crane: Eelectric overhead travelling crane or shorted as EOT crane is mounted to the top of the runways.

- Under running (under hung) overhead travelling crane: Electric overhead crane with the end trucks attached and supported to the flanges on the bottom of the runway beams.

Double girder overhead crane installation

Single girder overhead crane installation

Double girder gantry crane installation

Single girder gantry crane installation

Single leg gantry crane installation

Floor jib crane installation

Wall jib crane installation

Suspension crane installation

On selecting the right overhead travelling crane, there are many factors that need to be considered, such as, the following: What is the load being lifted? Will this be operated indoors or outdoors? What is the dimensions of the building? What's the crane the span? And what's more, how often will it be in use? Our overhead crane engineering can provide a complete package of crane services including the footing design, crane runway design and travelfling crane design. Our overhead crane engineers can provide the expertise to help you choose the right lifting crane equipment for your specific application.

Our overhead travelling crane equipment is widely used in many industries including steel fabrication, coil handling, construction, equipment maintainence, power,railroad construction as well as specialized hazardous or specialized environments such as medical, gas, mining, semi-conductor, biomass and food processing,etc. We can provide clean roomhoist crane as well as explosion proof , and spark resistant,as per your the crane specifications required.

Main crane specifications of general use overhead travelling cranes

The main overhead crane specifications andparameters of the general use overhead travelling cranes in terms of crane capacity, span, crane services duty and crane applications are presented for your reference. As for the process crane, please feel free to contact us directly to get your customized overhead travelling cranes.

Main crane specifications and parameters of general use overhead travelling cranes :

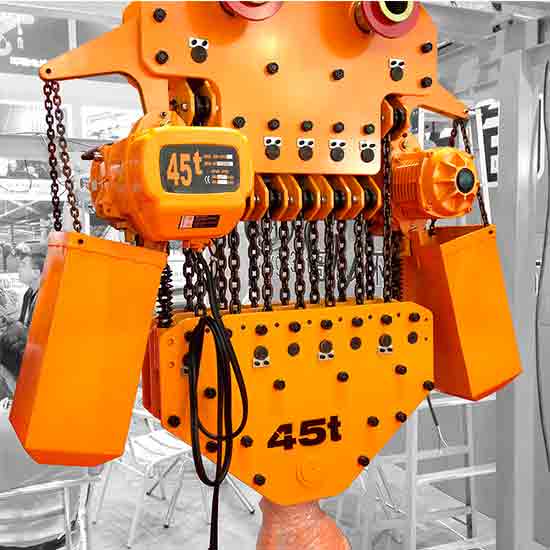

- Lifting capacity of overhead travelling cranes : 5 ton-550 ton, including 5 ton, 10 ton, 16/3.2 ton, 20/5 ton, 32/5 ton, 50/10 ton, 75/20 ton, 100/20 ton, 125/32 ton, 150/30 ton, 160/32 ton, 200/50 ton, 250/50 ton, 300 / 75 ton, 350/80 ton, 400/80 ton, 450/100 ton, 500/100 ton, 550/100 ton, etc.

- Span of electric overhead travelling cranes:10.5m-31.5meters,such as, 10.5m, 13.5m, 16.5m, 19.5m, 22.5m, 25.5m, 28.5m, 31.5m,

- Lifting height of electric overhead travelling cranes:1m-30m,

- Working duty of electric overhead travelling cranes: (A3, A4, A5, A6).

- Working ambient -25℃~+40℃, moisture ≤85%, altitude below 1000 meters,

- Power supply: 380V, 50Hz, 3phases, (Adjustable according to customer's different requirement).

Note:1. A5-Applied in working with not so much frequently, such as in the workshops of general machining and assembly or for maintaince .A6 -Applied in much more frequency work, such as auxiliary hoisting crane in metallurgy and casting workshop. A7-Applied in busy working and the hoisting of melted hot metal.

Non-standardoverhead travelling cranes with process crane designs are available for your specific applications.

Common overhead travelling crane terms

Crane Basic Concepts and Terms

1. Crane lifting capacity

- Rated capacity of overhead travelling crane :The rated capacity of crane includes the weight of the cargoes and the weight of the lifting devices and load-handling devices like crane hooks, crane grab buckets, electric magnetics, and equalizing beams, and many others, etc.

- Effective lifting capacity: The net maximum weight and capacity of the loads the overhead travelling crane is required to lift.

2. Span of overhead travelling crane

- Span of overhead travelling crane:The horizontal distance between the two rail centers /crane rails, on which the main girders are supported and moves along ,is referred to as the cane span of an overhead travelling crane.

3. Lifting height of overhead travelling crane

- Lifting height or hook height: The vertical distance between the crane hook and the floor. The crane hook height is determined by the crane runway height which is subject to the clear inside height of the building or the available space of the workshop. .

4. Crane service duty

The crane services duty or working class of an overhead travelliing crane is an important consideration when selecting a overhead crane for your needs. The average load intensity and loading cycles are used to classify crane working classes. Due to differences in average load intensity and loading cycles, two travelling cranes with the same lifting capacity, span, and size may have distinct working classes in terms of working class and the crane components and parts may experience various short term and long term loading conditions.

Different crane service classes exist according to various criteria. The Crane Manufacturers Association of America (CMAA) divides overhead traveling cranes into six categories based on typical load intensities and cycle count. While the International Organization for Standardization (ISO), the European Federation Standard (FEM), and the Hoist Manufacturer Institute (HMI) classify all crane hoists based on higher requirements such as the number of starts and the maximum running time per hour.(More information please check the Crane Service Duty Tab or please feel free to contact us. )

5. Speed of overhead travelling crane

- Lifting speed: In typical crane operation, the velocity at which loads within the rated lifting capacity travel vertically and steadily.

- Crane speed:Crane speed is the rate at which loads within a crane's rated lifting capacity move horizontally or along a runway.

- Trolley speed: In typical crane operation, the pace at which the trolley travels on the horizontal tracks with loads within the rated lifting capacity.

- Note: Whether a single speed, double speed, or frequency drive is required should be indicated.

6. Wheel pressure

- The wheel pressure refers to the pressure when the trolley moves to the limiting position on one side with weights within the crane's rated lifting capacity on electric overhead travelling cranes.

- Note: Crane wheel pressure is proportional to the bearing capacity of the building's steel frame.

Crane Service Duty Classess

Crane service can be classified into various classifications based on various standards. ASME, CMAA, HMI, ISO, CEN EN, FEM, and OSHA are the most commonly utilized standards. In the following, the FEM crane duty classes are presented for your reference.

FEM Crane duty class

Crane services are classified as Light, Medium, Heavy, or Very Heavy, according to FEM standards.

According to FEM standards, the following factors determine the crane services group:

- 1. Load spectrum, which depicts the frequency of loads with the highest and lowest lifting capacities across time.

- 2. The numbers of hoisting cycles over the crane's lifetime.

Different load spectrums as an example:

Light duty overhead travelling crane

Medium duty overhead travelling crane

Heavy duty overhead travelling crane

Very heavy overhead travelling crane

The crane services duty class of an electric overhead travelling crane is determined by many factors, and more information, please feel free to contact us to determine the right crane duty class for your electric overhead travelling crane.

Conclusion

Various crane duty classes based on various standards are different techniques to assist you in choosing the right crane or hoist for your application. Remember to consider the following factors when selecting a travelling crane or lifting hoist for your application, which you should check with your crane or hoist manufacturer:

- On average, hourly lifts and trolley and bridge movements.

- On average, the length of each movement.

- On average, the estimated weight of the loads that must be hoisted.

- Total daily operating time.

Types of electric overhead travelling crane

- Overhead travelling bridge cranes are available with capacity of 550 ton with simple single girder overhead travelling bridge crane designs for general usage as well as custom built double girder overhead travelling bridge cranes for all industries.

- Overhead travelling crane can be provided in multiple overhead crane configurations. Typical design includes single girder top running overhead crane, single girder underrunning overhead crane, double girder top running overhead crane and double girder underrunning overhead crane. Contact us to get your process designed overhead cranes.

Single Girder v.s Double Girder Overhead Travelling Cranes

Single girder overhead travelling cranes, which are made out of a single bridge girder beam attached to the runways, are a tried-and-true solution to a variety of material handling problems. When used correctly, these overhead cranes may provide years of service. They are very adjustable and can be equipped with manual chain hoists, electric chain hoists, or electric wire rope hoists for maximum versatility in your work area. Optional features of the single girder overhead travelling crane including Radio remote control, independent traveling pushbutton stations, anti-collision systems, bridge and trolley travel limitations, variable frequency control, bridge lights and warning bells or horn, and weight readout and many others.

Single girder overhead crane video

Double girder bridge travelling cranes have two bridge beams attached to the runways and are usually equipped with top-running electric wire rope trolley hoists, but depending on the application, they can also be equipped with top-running electric chain hoists. Double girder top running overhead travelling cranes can be equipped with underrunning trolley hoists, though this is not typical. 5-ton, 10 ton, 15 ton, 20 ton, 25 ton, 30 ton, 50 ton, 75 ton, and 100-ton overhead crane are the most popular product in our factory.

Double girder overhead crane video

Single Girder Under Running Overhead Crane

Underrunning, underhung, and underslung are all terms used to describe this type of overhead travelling crane. When used appropriately, under running overhead travelling cranes are extremely adaptable, with spans up to 75 feet and capacities up to 2 0 tons, however most spans are less less than 60 feet and capacities are less than 10 tons.

The design of these suspension single-girder overhead cranes allows for interlocking systems in which the load must be transferred from one bay to the next, transferred to a monorail, and then onto another crane, or transferred to a spur. These are typically offered as patented track designs, although they can also be made with wide flange or standard I-beam construction.Electric chain hoist or electric wire rope hoists are commonly used in overhead travelling cranes, but they can also be equipped with a pneumatic hoist or a manual hoir or chain block.

These single-girder overhead travelling cranes can be controlled by a pushbutton on the hoist, an independent moving pushbutton, or by remote radio control.

There are special constructions available for spark resistant, explosion proof, or food grade applications. Workstation overhead cranes are a type of underrunning overhead crane. These are typically offered for lighter weights handling and are manually pushed, however they usually use an electric or air chain hoist.

Advantages of a Single Girder Under Running Overhead Crane

- The hoist trolley can go beneath the runway, allowing for the best final approach.

- For cost savings on runway structure, the system can be included into building design.

- Due to the coupling of columns to headers and headers to the runway, freestanding workstation overhead crane systems are very rigid.

- Interlocking with another travelling crane or monorail is possible.

- Low headroom design, particularly with notched bridge beams that take use of the runway's depth.

- Travelling crane installation is easier, resulting in lower installation costs.

- Crane maintenance is simple.

Main parts & components

The lifting system, controlling system, crane frame, and among other things, are the primary spare parts of an overhead traveling crane. Parts and crane components for overhead traveling cranes include the main crane girder, end girder trucks or end carriages, electrical resistor, trolley, trolley frame, and hook blocking frame,etc.

For single girder overhead travelling cranes, double girder overhead travelling cranes, top running overhead travelling cranes, underhung overhead travelling cranes, and processed industrial cranes, various types of overhead travelling crane parts and components are available. On the basis of your spare part drawing, we deliver tailored Overhead Travelling Cranes parts and processed Overhead Travelling Cranes components. For further information, please contact us.

Crane parts name:Main girder/ bridge crane

One of the most significant crane sections is the main girder, which supports the trolley or hoist. Crane main girders are categorised as truss girders, box girders, single girders, and double girders, and many other types of structures. Single girder, double girder, triple girder, box girder, truss grider, and other girder designs are available. Please do not hesitate to contact us if you require crane girder design.

Single girder overhead travelling crane

Double girder overhead travelling crane

Top running overhead travelling crane

Under hung / under running overhead travelling crane

Crane parts name:End beam/ end carriage

The main girder, which supports the trolley or hoist, is one of the most important crane parts. Truss girders, box girders, single girders, and double girders, as well as many other types of constructions, are all examples of crane main girders. There are designs for single girders, double girders, triple girders, box girders, truss griders, and process girders for your applications. If you require crane girder design, please contact us.

Single girder crane end carriage - Top running crane design

Double girder crane end carriages - Top running crane design

Double girdder overhead crane end carriage - Under hung crane design

Single girder overhead crane end carriage - Underrunning crane design

Travelling crane hoists

Electric wire rope hoist for single girder overhead travelling crane

Electric cable hoist for double girder overhead travelling crane

Electric chain hoist for all type of overhead travelling cranes

FEM stanard electric hoist for overhead travelling cranes

Crane winch

European style open winch for overhead travelling crane

Chinese style open winch for overhead travelling crane

Chinese style open winch for overhead travelling crane

European style open winch for overhead travelling crane

Crane control

The driver's cabin of overhead travelling cranes and gantry cranes can be different depending on crane designs, and they can also be positioned at different positions of overhead travelling cranes and gantry cranes. Crane operator or driver's cabin, a buffer, a stairway, and a handrail for overhead traveling cranes and gantry cranes are aslo available.

Cabin control for overhead travelling crane and gantry crane

Radio control for overhead travelling crane

Wireless remote crane control for overhead crane

Pendant crane control

Main types of overhead travelling cranes offering

Usually the main Overhead Travelling Cranes types are as the following:

Single Girder Overhead Travelling Bridge Crane

- Chinese Type Robust & Economial Single Girder Hoist Overhead Crane

- European Standard Small & Light-weighted Hoist Single Girder Overhead Crane

- Suspension Crane, Ceiling-mounted Single Girder Overhead Crane

- European Type Underslung Crane

- Explosion proof type Single Girder overhead crane

- Low Headroom crane type Single Girder Overhead Crane

Double Girder Overhead Travelling Bridge Crane

- Hoist Trolley Double Girder Overhead Crane

- Winch trolley Double Girder Overhead Crane

- European Double Girder Travelling Bridge Crane

- Explosion Proof Double Girder Travelling Bridge Crane

By lifting devices

Electric chain hoists mounted on hook, lug, manual or electric hoist trolley for types of electric chain hoist cranes with capacity of 500kg, 5 ton, 10 ton, 32 ton.

Types of wire rope hoists designs for overhead hoist cranes- explosion-proof cable hoist, low profile wire hoist & single & double girder hoists for your hoist cranes.

European standard overhead hoist crane, Small overhead crane:European single girder overhead cranes, compact FEM hoist crane design, small & light overhead hoist crane.

1 ton -10 ton underhung bridge crane, light single girder overhead crane design, suspended on overhead roof, free floor space, economical underhung crane.

FEM/ DIN open winch bridge crane-European standard double girder overhead crane with open winch trolley, your heavy duty winch crane up to 320 ton.

Portable gantry crane & Economical mobile gantry-250 kg - 10 ton portable gantry cranes & mobile gantry cranes with adjustable / fixed gantry for small & light material handling.

Single girder hoist gantry cranes, FEM,DIN & ISO standards: Single beam gantry cranes, European style box girder, FEM hoists for 3 ton, 5 ton, 10 ton, & 16 ton load handling.

European style double girder hoist trolley gantry cranes: European type double girder gantry cranes with FEM standard wire rope hoists trolley with capacity of 5 ton up to 75 ton for sale.

Free standing jib crane-Pillar mounted jib crane is a free standing jib crane with pillar jib mounted on floor, for short & crowded lifting, capacity up to 16 ton.

Wall mounted jib crane & wall bracket jib crane with I beam & tie rod design for light duty handling with capacity up 2 ton. or less building structure changes.

Light crane kbk system-kbk light crane systems, flexible kbk crane & rigid kbk crane, modular crane design, cost-effective workstation crane solution, tailored light duty bridge crane.

How to select Overhead Travelling Cranes

You will receive multiple Overhead Travelling Cranes quotations from crane builders after making an Overhead Travelling Cranes inquiry. How can you find the most affordable crane estimates among them? It is necessary to compare the numerous Overhead Travelling Cranes quotes.

How to select Overhead Travelling Cranes builder

What matters is that you work with the correct crane builder for your Overhead Travelling Cranes project. You can compare Overhead Travelling Cranes manufacturers based on a variety of factors, including referrals, industry events or trade fairs, and internet research.

Ask for suggestions

Visit a factory or plant that has Overhead Travelling Cranes installed and seek advice. Find out if your present customers, vendors, or suppliers, as well as all of your contacts, use overhead travelling crane. equipment. Assuming that's the case, if they don't mind, ask for a referral for crane builders. It would be preferable if they could introduce you to an Overhead Travelling Cranes builder with whom they are happy to work.

Attend industry trade show or events

At trade exhibits, you can learn a lot about Overhead Travelling Cranes manufacturers and suppliers, which are companies that specialize in the development and production of overhead travelling cranes.

Checking the exhibitor list and contacting the crane maker you're interested in and paying a quick visit to their booth or scheduling a factory visit after the show will save you a lot of time.

Study crane builders on Google

Use terms like "Overhead Travelling Cranes manufactures or company Pakistan," "Overhead Travelling Cranes supplier Bangladesh," or "Overhead Travelling Cranes company in Middle East" to find the crane manufacturers you're looking for.

Keep Overhead Travelling Cranes price competitive

Crane builder from China

When comparing overhead bids, the price of overhead traveling cranes is critical. What factors influence the pricing of overhead traveling cranes? It primarily consists of the following:

- The order's crane quantity - How many overhead traveling cranes are required for your project?

- Modle/ Types of cranes - Overhead traveling cranes come in a variety of shapes and sizes.There are several different types of overhead traveling cranes to choose from. Each variety has its own characteristics that may influence the price.

- Lifting capacity: The lifting capacity of Overhead Travelling Cranes is determined by three factors: 1) the weight of the loads to be hoisted at a lift, 2) the weight of the associated riggings or below-the-hook lifters, and 3) additional future usage or capability considerations.

- Crane span is the horizontal distance between the runway rails from center to center.

- Lift height refers to how high the loads must be elevated above the ground.

- Crane duty class/number of lifts per hour: In general, higher service class overhead traveling cranes will necessitate additional engineering and specialized crane parts and components to meet complex lifting challenges.

- Hook approach: This refers to how close a crane hook can reach to the end of a bridge or runway, as well as considerations for both the trolley hook and crane/runway hook approaches.

- Will the overhead travelling crane be electrically driven, hand-operated, or pneumatically powered?

- Applicaiton conditions-The cost of an Overhead Travelling Cranes is affected by the operating environment, such as, the harsh, obstructed, or dangerous environment needs more durable cranes with higher price.

- Operation speed - The more quickly the crane must function, the more expensive it will be to design, source, and arrange the different crane components.

- Crane controls: It will be necessary to consider how the operator is loading or unloading material. There three selections: a radio command Is it better to have a pendant or a Crane cab.

- Crane running - Where is the Crane runway? Is it a runway for a new building? Or a runway built inside an existing structure?

The pricing of Overhead Travelling Cranes is influenced by a number of factors. Learn more please feel free to contact us.

Other items needed to compared

- Project specifications- For an overhead travelling crane project of this scale, it's critical that the crane manufacturer quotes the crane using the same specifications and data.

- Warranty- The crane maker's warranty terms on workmanship, components, and materials should be thoroughly understood.

- Incidentals-Any additional charges that are not included in the quote, such as steel price fluctuations, taxes, freight charges, and other expenses.

- Ensure that the crane builder provides a clear timeframe for the crane project, including the installation of Overhead Travelling Cranes if necessary.

After comparing Overhead Travelling Cranes quotes, you'll know which Overhead Travelling Cranes manufacturers are the best fit for you. When it comes to choosing an Overhead Travelling Cranes service provider, please wait until you have received an Overhead Travelling Cranes quote from us, one of the top crane makers who has earned client satisfaction by a down-to-earth attitude and high quality.