Light Duty Wall Mounted Jib Crane 0.75 Ton & 1 Ton for Sale

Light Duty Wall Mounted Jib Crane Philippines. Custom light duty jib crane, with wall mounted crane design, custom jib capacity 0.75 Ton & 1 Ton for Sale.

Category: Jib Crane Capacity & Tonnages

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Light Duty Wall Mounted Jib Crane 0.75 Ton & 1 Ton for Sale

Light Duty Wall Mounted Jib Crane 0.75 Ton & 1 Ton for Sale. Light Duty Wall Mounted Jib Crane Philippines. Custom light duty jib crane, with wall mounted crane design, custom jib capacity 0.75 Ton & 1 Ton for Sale.

Case Study: Enhancing Efficiency and Productivity with Light Duty Wall Mounted Jib Cranes in the Philippines

In the bustling industrial landscape of the Philippines, the need for efficient and reliable material handling solutions is paramount. To address this demand, a leading equipment supplier introduced a range of Light Duty Wall Mounted Jib Cranes, tailored to meet the unique requirements of businesses across the nation. This case study explores how these innovative cranes have significantly improved lifting operations and elevated productivity for various industries.

Client Background and Lifting Requirements

The client, a reputable supplier of industrial equipment, identified a gap in the market for versatile and spacesaving lifting solutions. Recognizing the importance of customizability and efficiency, they introduced their Light Duty Wall Mounted Jib Cranes with a focus on capacities of 0.75 ton and 1 ton.

Prior to the introduction of these cranes, businesses faced challenges in efficiently moving and lifting loads within confined spaces. Conventional lifting methods often consumed valuable floor space and required extensive manual labor, resulting in increased downtime and reduced overall productivity.

Light Duty Wall Mounted Jib Crane Solution Offered:

The Light Duty Wall Mounted Jib Cranes provided an optimal solution for businesses seeking to streamline their material handling processes. With custom designs that featured wallmounted capabilities, these cranes efficiently utilized vertical space and allowed for precise load positioning. The cranes were offered in two variants: 0.75 ton and 1 ton, each tailored to specific lifting requirements.

Overview of 0.75 ton crane for sale Philippines

- Crane type: light duty wall mounted jib crane

- Cranes specifications: BX0.75T3M H8M,

- Crane power supply: 380V60HZ3P

0.75 ton jib crane, light duty wall mounted jib crane cross beam

0.75 ton jib crane hoist for light duty jib crane for sale Philippines

0.75 ton electric chain hoist

Overview of 1 ton crane for sale Philippines

- Crane type: light duty wall mounted jib crane

- Cranes specifications:BX1T5M H3M;

- Crane power supply: 380V60HZ3P

1 ton jib crane, light duty wall mounted jib crane for sale, good price

1 ton jib crane hoist for sale Philippines

1 ton electric chain hoist trolley for sale

Additionally, the client introduced 2ton electric chain hoists with specifications as follows:

Overview of 2 ton electric chain hoists

- Main specifications: 2T4M

- Crane power supply: 220V60HZ3P;

2 ton electric chain hoist trolley

2 ton electric chain hoist for sale Philippines

Features of light duty wall mounted jib crane with cantilever jib crane design

The Light Duty Wall Mounted Jib Crane with Cantilever Jib Crane Design offers a range of features that make it a versatile and efficient solution for various material handling needs. Here are some key features of this type of crane:

- Cantilever Jib Design: The cantilever jib design of the crane ensures that the load can be extended beyond the crane's support structure, allowing for a larger working area without the obstruction of a central column. This design maximizes the utilization of available space.

- WallMounted Configuration: The crane is securely mounted on a wall or vertical surface, further saving floor space and providing a clear working area underneath. This is particularly useful in areas where floor space is limited.

- Light Duty Lifting Capacity: Designed for light duty lifting applications, this crane is suitable for tasks that involve loads within the specified weight capacities (0.75 ton and 1 ton). It is ideal for tasks such as loading/unloading workstations, assembly lines, and maintenance work.

- Customizable Capacities: The crane is available in multiple lifting capacities, allowing businesses to choose the appropriate model based on their specific load requirements.

- Flexible Rotation: The jib arm offers a full 180degree rotation, providing flexibility in positioning loads precisely where they are needed. This range of rotation enhances efficiency and reduces the need for repositioning.

- Precise Load Control: The design allows for precise load control, enabling operators to maneuver and position items with accuracy. This is crucial for delicate operations and prevents potential damage to the load.

- Enhanced Safety Features: Builtin safety features, such as limit switches and overload protection, help prevent accidents and ensure the crane's safe operation.

- Easy Operation: The jib crane is designed for userfriendly operation. Controls are intuitive, and the crane can be easily maneuvered by a single operator.

- Reduced Manual Labor: By providing an efficient lifting solution, the crane minimizes the need for manual labor, reducing strain on workers and enhancing overall productivity.

- Durable Construction: The crane is constructed using highquality materials to ensure durability and longterm reliability. This is essential for withstanding the demands of industrial environments.

- Quick Installation: The wallmounted design simplifies installation, and the crane can be integrated into existing spaces without the need for extensive modifications.

- Suitable for Various Industries: The versatility of the crane makes it suitable for a wide range of industries, including manufacturing, warehouses, workshops, and maintenance facilities.

In summary, the Light Duty Wall Mounted Jib Crane with Cantilever Jib Crane Design offers an efficient and spacesaving solution for light duty lifting tasks. Its cantilever jib design, wallmounted configuration, and precise load control features make it an excellent choice for businesses looking to optimize their material handling processes while maintaining safety and productivity.

Benifits of using electric chain hoists

Electric chain hoists offer several benefits when used in conjunction with light duty cranes, such as wallmounted jib cranes. Here are some of the key advantages:

- Efficient Lifting: Electric chain hoists provide smooth and efficient lifting of loads, reducing the manual effort required to move objects. This efficiency translates to improved productivity and reduced strain on operators.

- Precise Positioning: Electric chain hoists offer precise control over load positioning, allowing for accurate placement of objects. This is crucial in tasks that require delicate handling or positioning within tight spaces.

- Enhanced Safety: Electric chain hoists are equipped with safety features like overload protection and limit switches. These features prevent the hoist from lifting loads beyond its capacity, reducing the risk of accidents and equipment damage.

- Reduced Operator Fatigue: Electric chain hoists handle the lifting process, reducing the physical strain on operators. This results in less operator fatigue and lowers the likelihood of human error due to exhaustion.

- Consistent Performance: Electric chain hoists provide consistent and repeatable performance, ensuring that loads are lifted and moved uniformly. This is particularly important for maintaining product quality and avoiding damage during lifting.

- Variety of Lifting Heights: Electric chain hoists can be configured to accommodate different lifting heights. This flexibility allows them to be used in various settings and applications.

- Remote Control Options: Many electric chain hoists come with remote control capabilities, enabling operators to control the lifting process from a distance. This is advantageous for maintaining a safe distance from the load and improving visibility during lifting.

- Adaptability to Different Loads:

Electric chain hoists are designed to handle a wide range of load types and sizes. This adaptability makes them suitable for various industries and tasks. - Quick Installation: Installing an electric chain hoist onto a light duty crane is relatively straightforward, minimizing downtime during setup.

- Low Maintenance: Electric chain hoists generally require less maintenance compared to manual lifting methods. Routine inspections and periodic maintenance ensure their continued reliable performance.

- CostEffective Solution: While providing automated lifting capabilities, electric chain hoists are often more affordable than larger, more complex lifting systems. They offer a costeffective solution for light duty lifting needs.

- Space Efficiency: Electric chain hoists are compact in design, making them wellsuited for use with light duty cranes where space might be limited. They don't require additional floor space or manual labor, helping to maximize available workspace.

In conclusion, electric chain hoists offer a range of benefits when paired with light duty cranes. They enhance lifting efficiency, safety, and precision, while also contributing to operator comfort and overall productivity. These advantages make them a valuable addition to various industries that require light duty lifting solutions.

Types of light duty cranes for your selection

There are several types of light duty cranes available for various lifting and material handling needs. Here are a few common types that you might consider:

Light Duty Wall Mounted Jib Crane:

As mentioned earlier, these cranes are wallmounted and feature a cantilever jib design. They are suitable for lifting and moving loads within a limited area, making them ideal for workstations, assembly lines, and maintenance tasks.

Features:

- Wallmounted design with a cantilever jib for efficient use of space.

- Typically lower lifting capacities (up to 1 ton).

- 180degree rotation for versatile load positioning.

- Customizable capacities and configurations.

Benefits:

- Maximizes floor space, making it ideal for compact work areas.

- Provides precise load control and positioning.

- Reduces operator strain and improves productivity.

- Enhances safety with builtin limit switches and overload protection.

Typical Applications:

- Small manufacturing workshops for assembly, machining, and maintenance.

- Warehouses for loading/unloading goods from trucks or shelves.

- Retail settings for managing smaller items or displays.

Light Duty Free Standing Jib Crane:

Similar to wallmounted jib cranes, these cranes are freestanding and do not require wall support. They offer greater flexibility in terms of positioning and can be placed in open spaces.

Features:

- Selfsupporting structure without the need for wall attachment.

- Offers versatile load positioning in open spaces.

- Available with cantilever or fullcircle jib designs.

- Typically handles lower lifting capacities.

Benefits:

- Provides flexible placement options within a facility.

- Offers efficient material handling without wall constraints.

- Enhances productivity and reduces manual effort.

- Suitable for areas lacking suitable wall support.

Typical Applications:

- Small manufacturing workshops requiring flexible load movement.

- Work areas with limited or no wall space for crane installation.

- Loading/unloading tasks in open spaces or outdoor environments.

A monorail crane consists of a single rail along which a trolley or hoist moves. They are suitable for linear lifting and transfer applications, such as moving materials along an assembly line.

Features:

- Single rail system with a trolley or hoist for linear lifting.

- Designed for moving loads along a specific path.

- Offers various configurations including single and double girder setups.

Benefits:

- Optimizes material movement along assembly lines or production processes.

- Provides efficient and controlled transfer of items between workstations.

- Reduces the need for manual labor, enhancing productivity.

- Suitable for environments with linear load handling requirements.

Typical Applications:

- Assembly lines in manufacturing plants for seamless material flow.

- Warehouses with linear pathways for organized storage and retrieval.

- Production facilities requiring controlled movement of parts or products.

These additional types of light duty cranes offer further options for businesses to select the most suitable solution based on their specific lifting needs and workspace characteristics.

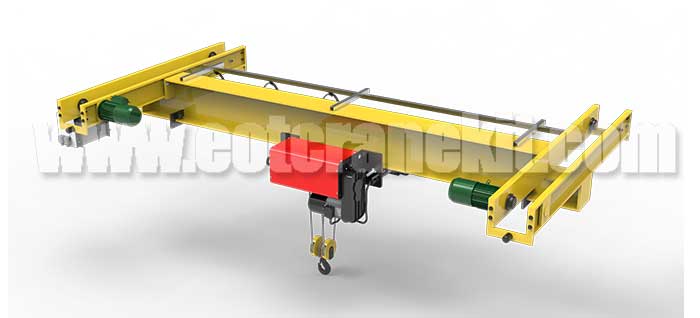

Light Duty Overhead Crane:

Single girder top running crane

Single girder top running overhead cranes are one types of the most frequently used lifting equipment used for indoor applications, which are widely used in various workshopss, warhouses, etcs.

Underhung cranes are suspended from overhead building structures and can move along the length of the building. They are often used when floor space needs to be maximized.

Gantry cranes have legs that can move on wheels or rails, allowing them to straddle objects or work areas. They are versatile and can be used for outdoor or indoor applications.

Features:

- Equipped with movable legs on wheels or rails for flexibility.

- Offers the ability to straddle objects or work areas.

- Suitable for both indoor and outdoor applications.

Benefits:

- Versatile for various workspaces and environments.

- Can be positioned over objects or machinery as needed.

- Provides efficient and controlled movement of loads.

Typical Applications:

- Construction sites requiring movable lifting solutions.

- Loading/unloading tasks in outdoor areas.

- Warehouses with changing layout requirements.

Similar to gantry cranes, portable gantry cranes are lightweight and can be moved to different locations. They offer flexibility for temporary lifting needs.

Features:

- Lightweight and easily movable crane structure.

- Designed for temporary lifting needs.

- Offers quick assembly and disassembly.

Benefits:

- Provides flexibility for intermittent lifting tasks.

- Eliminates the need for permanent installation.

- Offers convenience for use in different locations.

Typical Applications:

- Maintenance tasks requiring lifting at various locations.

- Temporary workspaces needing lifting solutions ondemand.

- Events or projects with changing lifting requirements.

Articulating Jib Crane:

An articulating jib crane features a pivoting arm that can reach around obstacles and access tight spaces. This type of crane is suitable for more complex lifting scenarios.

Features:

- Pivoting arm design for reaching around obstacles.

- Enhanced flexibility in accessing tight spaces.

- Can rotate and pivot to multiple angles.

Benefits:

- Suitable for complex lifting scenarios.

- Provides precise load positioning in challenging areas.

- Reduces the need for multiple crane setups.

Typical Applications:

- Workstations with limited access points.

- Production areas with irregularly shaped objects.

- Facilities where loads need to be maneuvered with precision.

These cranes are mounted on a pillar or column instead of a wall. They offer a combination of features from wallmounted and freestanding jib cranes.

Features:

- Mounted on a pillar or column, combining features of wallmounted and freestanding cranes.

- Offers a stable and spaceefficient solution.

- Can be customized to various lifting capacities.

Benefits:

- Utilizes existing structural support for installation.

- Provides flexibility in load positioning without wall constraints.

- Offers an efficient compromise between different crane types.

Typical Applications:

- Workshops with limited wall space and floor area.

- Manufacturing settings requiring efficient load movement.

- Maintenance tasks where wall mounting isn't feasible.

Telescopic Jib Crane:

A telescopic jib crane has an extendable arm that provides additional reach when needed. This is useful for tasks that require lifting over obstacles or into deep spaces.

Features:

- Extendable arm for increased reach.

- Provides extra length for lifting over obstacles or into deep spaces.

- Offers flexibility in load positioning.

Benefits:

- Adapts to varying lifting scenarios.

- Enhances versatility in reaching objects at different distances.

- Reduces the need for repositioning the crane.

Typical Applications:

- Warehouses or workshops with obstacles to lift over.

- Loading/unloading tasks with varying load placement.

- Environments where adjustable reach is crucial.

Floor Mounted Jib Crane:

These cranes are directly mounted to the floor and can be positioned according to the lifting requirements. They are often used in workshops and smaller industrial spaces.

Features:

- Directly mounted to the floor surface.

- Offers flexibility in positioning based on lifting requirements.

- Suitable for smaller industrial spaces.

Benefits:

- Provides spaceefficient lifting solution.

- Suitable for workshops and compact work areas.

- Offers efficient load movement within defined space.

Typical Applications:

- Small manufacturing facilities with limited space.

- Maintenance tasks in confined areas.

- Workstations requiring localized lifting capabilities.

These additional types of light duty cranes expand the range of options available for various lifting needs and workspace configurations. Choosing the right crane type depends on factors such as available space, load requirements, and the specific demands of the application.

When selecting a light duty crane, it's essential to consider factors such as the lifting capacity, working environment, available space, and the type of materials being handled. Each type of crane has its advantages and is suitable for specific applications. Consulting with crane experts or suppliers can help you choose the best type of light duty crane for your needs.

The introduction of Light Duty Wall Mounted Jib Cranes in the Philippines has demonstrated how tailored lifting solutions can revolutionize material handling processes. By providing efficient load movement, space optimization, and customization, these cranes have become an essential asset for industries seeking to enhance productivity and safety. As businesses continue to seek innovative solutions, these cranes stand as a testament to the power of technology in driving industrial progress.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch