How to Secure Load Handing of Your Overhead Travelling Crane?

What are OSHA load handling regulation to ensure your overhead crane &gantry crane safety? How to ensure overhead crane load handling operation? Read on load handling safety.

Secure Overhead Crane Load Handling to Improve Crane Operation Safety and Efficiency

Securing your load is crucial since it concerns both safety and efficiency. There are a number of circumstances when we fail to double-check our load. As a result, we are forced to experience terrible events and circumstances. So, in this section, we'll go over all you need to know about safeguarding your load. It will help you realize the necessity of cargo security. It is critical not only for the craneoperators, but also for the customers and general public. As a result, we'll try to make sense of everything that comes with securing the loads handling.

Regulations of OSHA of load safety

The methods for safe load handling are covered in the following OSHA standard, which includes observing rated load limits, attaching loads, transferring loads, and testing load limit switches. These guidelines include equipment safety as well as crane operators' responsibilities in safe crane operation.

OSHA 1910.179 Overhead & Gantry Cranes Regulations

The following excerpt is taken directly from OSHA 1910.179*

Load Dimensions:Except as stipulated in paragraph (k) of this section, the crane shall not be loaded over its rated load.

Securing the load:

- The hoist chain or rope must not be wrapped around the cargo and must be free of kinks or twists.

- Slings or other permitted methods must be used to secure the load to the load block hook.

- Care must be taken to ensure that the sling passes over any impediments.

Moving the load:

- Before lifting the load more than a few inches, it must be securely fastened and balanced in the sling or lifting device.

- Before starting to hoist the following conditions shall be noted:

- The hoist rope must not kink.

- Do not twist several part lines around each other.

- The hook must be brought over the cargo in a way that prevents it from swinging.

- During hoisting care shall be taken that:

- oThe moving load does not accelerate or decelerate suddenly.

- oThere are no impediments in the path of the load.

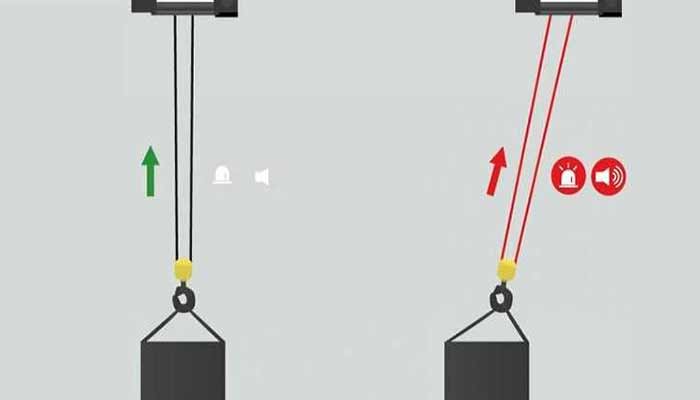

- Cranes shall not be utilized for side pulls unless specifically approved by a responsible person who has established that the crane's stability will not be jeopardized and that various crane components will not be overstressed.

- There shall be no raising, lowering, or traveling while any employee is on the load or hook.

- The operator must avoid transporting loads above persons, according to the employer's requirements.

- Each time a weight approaching the rated load is handled, the operator must test the brakes. By lifting the load a few inches and applying the brakes, the brakes will be checked.

- The load must not be lowered below the point when the hoisting drum has less than two full wraps of rope.

- When two or more cranes are utilized to hoist a weight, the operation must be overseen by a qualified responsible person. He is responsible for analyzing the operation and instructing all people involved in the right location, rigging of the load, and motions.

- While the load is suspended, the employer must ensure that the operator does not abandon his position at the controls.

- The warning signal must be issued when the bridge is first started and when the load or hook approaches or passes over personnel.

Hoist limit switch:

- Each hoist's higher limit switch must be tested under no load at the start of each operator's shift.

- Extreme caution must be taken; the block must be "inched" into the limit or run in slowly. If the switch does not work properly, the designated person must be alerted promptly.

- The hoist limit switch, which regulates the load block's upper travel limit, must never be utilized as an operating control.

What you can do to ensure your load handling safety?

What to consider when it comes to securing the load? The following factors needs to be considered to secure your load handling:

Be aware of load limit.

It's the most important thing you can do. Before you place your load, double-check the load limit. When you overburden a vehicle, you endanger both the driver and the workers. As a result, you must stay away from it at all costs. Some operators will appear to be overconfident in their abilities. They believe that if the load is too heavy, their instincts will alert them. It is, however, not the appropriate thing to do. If you witness the operator making these kind of decisions, you must intervene as soon as possible.

You must be aware that each piece of heavy equipment you are about to operate has a certain weight limit. You can learn about the load limit by looking at the data plate. If you're not sure about the limit, you can verify the supplier's load-measuring system. It will provide you with a general understanding.

Regular inspection during transporting

The second step is to inspect your cargo on a regular basis while moving it. It is one of the most important procedures to perform if you are transporting your load over a long distance. It will assist you in making certain that everything is in its proper position. Furthermore, it will assure the shipment's safety. You must be aware that as a result of movement, straps and chains can stretch and shift. A regular halt will allow you to inspect those items and, if necessary, tighten them.

Ensure your rigging in good conditions.

Make that the lashings, slings, and other restraint equipment are in good working order. It is a well-known fact that you must take care of the tools you use to secure your cargo. You may need to update them before using them in your apps if their condition isn't up to par. If you're using straps or slings that aren't in the optimum shape, they may break during the travel.

As a result, you must inspect the gears before fastening your load. It's time to take action if you notice any evidence of damage or wear patterns. If you are unable to fix them, your best option is to replace them. You must, therefore, remove them as quickly as possible.

Regular maintenance of the hoist is essential.

It is critical to maintain your hoist on a regular basis to ensure your safety. It will also safeguard the safety of those operating in your vicinity. The hoist, whether it's on a crane or a truck, needs to be maintained on a regular basis. Otherwise, things falling from the hoist can be quite dangerous to you. Check to see if your hoist is in good operating order. Regular maintenance will also ensure that you understand its limitations. Never venture beyond the hoist's confines.

Make sure centre of gravity

In addition to protecting the load, you must ensure that the stack is balanced correctly. Otherwise, the off-balance loads could cause problems. It's possible, for example, that the load will fall out. Similarly, it may wreak havoc on the brake's condition.

What are the benefits of securing load?

Securing your cargo has various advantages. Its importance in terms of safety has already been addressed. We'll go over the benefits of safeguarding the cargoes here so you can make the best option possible in the future.

- It will be in charge of ensuring the safety of anyone working with cargo. Furthermore, it will safeguard the shipment.

- If you can precisely secure load, you can stay in compliance with laws and regulations. Otherwise, it will be assumed that you are breaking the law.

- If you secure the load precisely, your equipment and carrier will be safe.

- If you can provide the highest level of safety, your company's reputation will improve. It will show that you are dedicated to your task.

- Debris and spills will no longer be an issue.

So, these are the facts you should be aware of when it comes to load securing. Examine them thoroughly before making your decision.