Your Trusted Semi Gantry Crane Manufacturer & Supplier

Semi Gantry Crane, Industrial Half Gantry & Single Leg Gantry Cranes

Semi-Gantry Cranes 1 Ton, 3 Ton, 5 Ton, 10 Ton, 20 Ton, 32 Tons Specifications and Options for Your Needs

Explore semi-gantry cranes from 1 to 32 tons, offering customizable specifications and options to meet diverse lifting needs efficiently.

What is a Semi-Gantry Crane? A semi-gantry crane is a type of overhead crane that combines elements of both gantry and bridge crane designs. Unlike a full gantry crane, which typically has both legs mounted on tracks, a semi-gantry crane has one end supported by a track system while the other end is fixed to a building structure or another support. This design allows for a versatile range of lifting and moving tasks while offering the advantage of reduced space requirements compared to a full gantry system.

Definition and Unique Features of Semi Gantry Cranes

Semi-gantry cranes are characterized by their asymmetric support structure. The crane's frame consists of a single side rail or track system, which supports the crane's hoist and trolley. The other side of the crane is typically supported by a wall-mounted rail or an overhead structure, allowing it to cover a significant span with a more compact footprint. This design is particularly advantageous in environments where space is limited or where a full gantry system would be impractical.

Key features of semi-gantry cranes include:

- High Lifting Capacity: Capable of handling a wide range of weights, from light loads to heavy materials.

- Versatility: Suitable for various lifting and moving tasks in diverse environments.

- Cost-Effectiveness: Generally more economical than full gantry cranes due to reduced structural requirements.

Capacity and Load Handling

Semi-gantry cranes come in a range of capacities, from light to heavy-duty options, catering to various lifting needs and operational requirements. Understanding the capacity range helps in selecting the appropriate crane for specific applications and ensures efficient and safe material handling.

1 Ton to 5 Tons Semi Gantry Crane

Suitable Environments and Applications

- Environments: Ideal for smaller workshops, repair shops, and small manufacturing facilities where space is constrained.

- Applications: Used for lifting lighter components, such as small machine parts, tools, and materials.

Advantages and Limitations

Advantages:

- Compact Size: Fits well in smaller spaces due to its lighter build.

- Cost-Effective: More affordable than larger capacity cranes.

- Flexibility: Useful for various light-duty tasks and environments.

Limitations:

- Limited Load Capacity: Not suitable for heavy materials or large components.

- Reduced Span: Generally, these cranes have a shorter span compared to larger models.

6 Tons to 15 Tons Semi Gantry Cranes

Ideal Use Cases and Industries

- Use Cases: Suitable for medium-sized manufacturing plants, warehouses, and assembly lines where moderate lifting capacity is required.

- Industries: Commonly used in automotive assembly, light industrial applications, and large workshops.

Performance Considerations

Performance:

- Increased Capacity: Capable of handling a broader range of materials and components.

- Operational Efficiency: Provides better performance for mid-sized tasks and higher throughput in industrial settings.

Considerations:

- Space Requirements: Needs more space than the 1-5 ton cranes but is still manageable in medium-sized facilities.

- Cost: Higher initial investment compared to smaller cranes, though still cost-effective relative to the increased capacity.

16 Tons to 32 Tons Semi Gantry Cranes

Key Applications and Environments

- Applications: Ideal for heavy-duty lifting tasks such as moving large machinery, heavy components, and bulky materials. Commonly used in large manufacturing plants, heavy industry, and construction sites.

- Environments: Suitable for environments where heavy loads are frequently handled, such as large warehouses, shipyards, and industrial facilities.

Operational Benefits

Operational Benefits:

- High Capacity: Can lift and move very heavy loads, making it suitable for demanding tasks.

- Durability: Built to handle rigorous use and challenging conditions, ensuring long-term performance.

- Versatility: Capable of performing a wide range of lifting tasks in heavy-duty applications.

Considerations:

- Space and Infrastructure: Requires ample space and robust infrastructure due to its larger size and weight.

- Cost: Higher investment required, but balanced by the ability to handle significant loads and improve operational efficiency.

Semi-gantry cranes in the 3 ton to 32 ton range offer a variety of optional designs and features to suit a broad spectrum of industrial applications. Whether you need enhanced performance, specialized features, or customized designs, these options help you tailor the crane to your specific needs:

Single Girder vs. Double Girder Semi Gantry Cranes

Single Girder Semi Gantry Crane

- Design: A single girder crane features one main horizontal beam, or girder, supported at each end by vertical legs. This design is typically used for lighter loads and is more economical.

- Capacity: Ideal for capacities ranging from 1 ton to 20 tons.

Advantages:

- Cost-Effective: Generally less expensive than double girder cranes.

- Compact Design: Suitable for lower building heights and smaller spaces.

- Simplicity: Fewer components can mean lower maintenance requirements and easier installation.

Limitations:

- Lower Capacity: Not suitable for extremely heavy loads compared to double girder cranes.

- Reduced Headroom: Limited vertical space due to the single girder design.

Double Girder Semi Gantry Cranes

- Design: A double girder crane features two main horizontal beams, providing additional strength and stability. This design supports heavier loads and offers more headroom.

- Capacity: Ideal for capacities ranging from 10 tons to over 100 tons.

Advantages:

- Higher Capacity: Capable of lifting heavier loads compared to single girder cranes.

- Increased Headroom: Provides more vertical space for lifting tall loads.

- Better Stability: More stable and rigid, suitable for precise and heavy-duty applications.

Limitations:

- Higher Cost: More expensive due to additional materials and complexity.

- Space Requirements: Requires more headroom and is generally bulkier.

European Style vs. Traditional Design Style

European Style Semi Gantry Cranes

Design: European style cranes are known for their compact, efficient design. They often feature advanced technology, such as lightweight materials, high-performance hoists, and optimized geometries.

Advantages:

- Space Efficiency: Designed to maximize usable space with compact dimensions.

- Advanced Technology: Incorporate modern features like variable frequency drives, which improve energy efficiency and control.

- High Safety Standards: Built to meet stringent European safety regulations.

Limitations:

- Higher Initial Cost: Advanced features and materials may lead to a higher initial purchase cost.

- Compatibility: May require specific maintenance and service support.

Traditional Design Style Semi Gantry Cranes

Design: Traditional cranes often feature more straightforward designs and construction methods. They are generally robust and reliable, with a focus on proven, conventional technologies.

Advantages:

- Cost-Effective: Usually less expensive due to simpler designs and standard components.

- Proven Reliability: Time-tested design principles ensure dependable performance.

- Ease of Maintenance: Standard components may be easier to source and replace.

Limitations:

- Less Space Efficiency: May have larger dimensions and less optimized space utilization.

- Older Technology: May lack some of the advanced features found in modern European designs.

Indoor Design vs. Outdoor Design Options

Indoor Design Semi Gantry Cranes

Design: Indoor cranes are designed to operate within a controlled environment, such as a warehouse or manufacturing facility. They often have features tailored to indoor use.

Advantages:

- Environmentally Controlled: Typically designed for cleaner, temperature-regulated environments.

- Space Utilization: Designed to maximize the use of indoor space.

- Less Corrosion Resistance Needed: Coatings and materials may focus less on weather resistance.

Limitations:

- Limited Weather Resistance: Not suited for exposure to harsh outdoor conditions.

Outdoor Design Semi Gantry Cranes

Design: Outdoor cranes are built to withstand varying weather conditions and environmental factors. They are constructed with materials and features that offer greater durability and protection.

Advantages:

- Weather Resistance: Equipped with weatherproof coatings and robust materials to handle rain, sun, and other elements.

- Durability: Built to endure harsh conditions and heavy-duty use.

- Greater Load Handling: Often designed to manage larger and heavier loads, suitable for outdoor construction sites or large industrial areas.

Limitations:

- Higher Cost: Advanced weather-resistant materials and features can increase the overall cost.

- Maintenance: Requires regular maintenance to manage exposure to environmental factors.

Hoist Types and Systems for Semi Gantry Cranes

When selecting a semi-gantry crane, choosing the right hoist type and system is crucial for ensuring optimal performance and safety. Below is a detailed overview of various hoist types and systems, including electric chain hoists, wire rope hoists, low headroom hoists, and explosion-proof hoists:

- Operation: Uses an electric motor to lift and lower loads by means of a chain. The motor drives a sprocket that moves the chain, allowing for smooth and efficient lifting.

- Design: Typically compact and straightforward, making it ideal for moderate lifting tasks.

Advantages

- Ease of Use: Simple controls and operation, suitable for frequent lifting tasks.

- Cost-Effective: Generally less expensive than wire rope hoists, making it an economical choice for lighter loads.

- Maintenance: Lower maintenance requirements due to fewer moving parts compared to wire rope systems.

Limitations

- Capacity: Typically used for lighter loads compared to wire rope hoists.

- Speed: Slower lifting speeds compared to some wire rope systems.

- Operation: Utilizes a wire rope wound around a drum, driven by an electric motor to lift and lower loads. Known for its durability and strength.

- Design: Robust and designed for heavy-duty applications.

Advantages

- High Capacity: Suitable for lifting heavier loads compared to chain hoists, often used for capacities above 5 tons.

- Durability: The wire rope is designed to withstand significant wear and tear, providing reliable performance in demanding environments.

- Speed and Precision: Generally offers higher lifting speeds and more precise control.

Limitations

- Cost: Higher initial cost compared to electric chain hoists.

- Maintenance: Requires regular inspection and maintenance of the wire rope and drum.

- Operation: Designed for environments where vertical space is limited. Features a compact design with reduced headroom requirements.

- Design: Integrates the hoist and trolley into a single compact unit to maximize available space.

Advantages

- Space Efficiency: Ideal for facilities with low ceiling heights or restricted vertical space.

- Increased Lifting Height: Maximizes the lifting height by minimizing the headroom required for the hoist.

Limitations

- Load Capacity: Often used for lighter to moderate loads due to design constraints.

- Special Requirements: May require customized installation to fit specific spatial constraints.

- Operation: Designed for use in hazardous environments where flammable gases, vapors, or dust may be present. Features explosion-proof enclosures and components.

- Design: Constructed with materials and design modifications that prevent ignition of explosive substances.

Advantages

- Safety: Meets stringent safety standards for operation in explosive or hazardous environments.

- Compliance: Adheres to regulatory requirements for safety in industries such as oil and gas, chemical processing, and mining.

Limitations

- Cost: Higher cost due to specialized design and materials.

- Maintenance: Requires careful maintenance to ensure continued safety and compliance.

Choosing the right hoist type and system depends on factors such as load capacity, environmental conditions, space constraints, and specific safety requirements. Understanding the advantages and limitations of each type will help you select the best option for your semi-gantry crane application.

Safety Features

Overload Protection

- Description: Systems that prevent lifting beyond the crane's rated capacity, reducing the risk of accidents and damage.

- Benefit: Enhances safety by avoiding overloading and extending the crane's operational life.

Anti-Sway Systems

- Description: Mechanisms that reduce load sway during lifting and movement, improving precision and safety.

- Benefit: Enhances load stability and reduces the risk of accidents caused by swinging loads.

Emergency Stop Buttons

- Description: Easily accessible emergency stop controls for immediate cessation of crane operations in case of an emergency.

- Benefit: Provides rapid response to unsafe conditions, improving overall operational safety.

Custom Finishes and Coatings

Anti-Corrosion Coatings

- Description: Specialized coatings that protect the crane from rust and corrosion, particularly useful in environments exposed to moisture or chemicals.

- Benefit: Extends the crane's durability and reduces maintenance needs, especially in harsh or corrosive environments.

Custom Paint Options

- Description: Choices for custom paint finishes to match company branding or aesthetic preferences.

- Benefit: Enhances the crane's visual integration with your facility and brand identity.

Additional Features

Remote Controls

- Description: Wireless or wired remote control systems for operating the crane from a distance, allowing for greater control and safety.

- Benefit: Increases operational convenience and safety by allowing the operator to control the crane from a safe location.

Integrated Lighting

- Description: Built-in lighting systems to improve visibility during low-light conditions or night operations.

- Benefit: Enhances safety and visibility during lifting operations, especially in poorly lit or outdoor areas.

Data Monitoring Systems

- Description: Systems for tracking crane performance, including load weights, operational hours, and maintenance needs.

- Benefit: Provides valuable insights for managing crane performance and scheduling maintenance, ensuring efficient and reliable operation.

These optional designs and features for 3 ton to 32 ton semi-gantry cranes allow you to customize the crane to meet your specific operational needs, improving performance, safety, and adaptability in various industrial environments.

Overview of Single Girder Electric Hoist Semi-Gantry Crane Specifications

The BMH Single Girder Electric Hoist Semi-Gantry Crane is designed for versatile lifting applications in various industrial settings. It combines the strength and reliability of a single girder design with the efficiency and precision of an electric hoist system. Below is an overview of its key specifications:

Crane Design

- Type: Single Girder Electric Hoist Semi-Gantry Crane

- Structure: Features a single horizontal girder supported on one side by vertical legs, with the other side mounted on rails or tracks.

- Configuration: Semi-gantry design allows for flexible placement, making it suitable for facilities with limited space or specific layout requirements.

Load Capacity

- Range: Typically available in capacities from 1 ton to 20 tons.

- Application: Suitable for handling moderate to heavy loads, depending on the specific model and configuration.

Span and Lifting Height

- Span: Customizable to fit the specific width of your workspace. Standard spans generally range from 3 meters to 10 meters.

- Lifting Height: Adjustable lifting height to accommodate various operational needs, typically ranging from 3 meters to 12 meters. Custom heights may be available based on requirements.

Electric Hoist Specifications

- Type: Electric Chain Hoist or Wire Rope Hoist

- Capacity: Matches the crane's load capacity, typically up to 20 tons.

- Lifting Speed: Standard lifting speeds range from 2 meters per minute to 10 meters per minute, depending on the load and application requirements.

- Control: Comes with a pendant control or wireless remote control for ease of operation.

Working Duty

- Classification: Designed for frequent use, with a working duty classification of M4 or M This indicates a high level of durability and reliability for moderate to heavy-duty applications.

- Usage: Suitable for industrial environments where regular lifting and movement of loads are required.

Power Supply

- Voltage: Common power supply options include 220V, 380V, or 415V, depending on regional electrical standards.

- Frequency: Typically operates at 50Hz or 60Hz.

- Phase: Available in single-phase or three-phase configurations to suit different power supply setups.

Special Features

- Anti-Corrosion Coating: Optional coatings for enhanced durability in harsh environments.

- Safety Features: Includes overload protection, emergency stop buttons, and limit switches to ensure safe operation.

- Custom Options: Can be equipped with additional features such as anti-sway systems, integrated lighting, and remote monitoring systems based on specific needs.

Dimensions and Weight

- Dimensions: Customized based on span, lifting height, and load capacity requirements. The compact design ensures efficient use of space.

- Weight: Varies depending on the crane's specifications and materials used. The single girder design typically results in a lighter overall structure compared to double girder cranes.

The BMH Single Girder Electric Hoist Semi-Gantry Crane offers a versatile and efficient solution for a range of industrial lifting applications. Its specifications and customizable options make it a valuable asset for facilities requiring reliable and flexible lifting solutions.

Single Girder Semi Gantry Crane 1 Ton to 20 Ton for Sale, Specification Table for Your Reference

Technical Parameter of BMH Electric Hoist Semi Gantry Crane |

||||||

Capacity |

t |

3 |

5 |

10 |

16 |

20 |

Span |

S(m) |

8~30 |

8~30 |

8~30 |

8~30 |

8~30 |

Lifting height |

m |

6~18 |

6~18 |

6~18 |

6~18 |

6~18 |

Lifting speed |

m/min |

8(0.8/8) |

8(0.8/8) |

7(0.7/7) |

5(0.35/5) |

3(0.33/3) |

Trolley speed |

m/min |

20(30) |

20(30) |

20(30) |

18 |

14 |

Crane speed |

m/min |

20(30) |

20(30) |

20(30) |

20(30) |

20(30) |

Work duty |

A3~A4 |

A3~A4 |

A3~A4 |

A3~A4 |

A3~A4 |

|

Track type |

P24 |

P24 P30 |

P30 P38 |

P30 P38 |

P38 P43 |

|

Overview of BMG Double Girder Semi-Gantry Crane Specifications

The BMG Double Girder Semi-Gantry Crane is engineered to deliver robust performance and versatility for heavy-duty lifting applications. Combining the strength of a double girder design with the flexibility of a semi-gantry configuration, this crane is ideal for demanding industrial environments.

Crane Design

- Type: Double Girder Semi-Gantry Crane

- Structure: Features two main horizontal girders supported on both sides by vertical legs, with one side mounted on rails or tracks. This design provides superior strength and stability.

- Configuration: The semi-gantry design allows for a combination of rail-mounted and floor-mounted operations, making it adaptable to various layout requirements.

Load Capacity

- Range: Typically available in capacities from 5 tons to 50 tons.

- Application: Suitable for handling heavy loads, providing exceptional lifting capabilities for demanding industrial tasks.

Span and Lifting Height

- Span: Customizable to fit the specific width of your workspace. Standard spans generally range from 6 meters to 30 meters, with options for larger spans based on requirements.

- Lifting Height: Adjustable lifting height to meet diverse operational needs, typically ranging from 5 meters to 20 meters. Custom heights can be accommodated.

Hoist Specifications

- Type: Electric Wire Rope Hoist

- Capacity: Matches the crane's load capacity, typically ranging from 5 tons to 50 tons.

- Lifting Speed: Standard lifting speeds range from 2 meters per minute to 15 meters per minute, depending on the load and application.

- Control: Comes with pendant control or wireless remote control for enhanced operational convenience.

Working Duty

- Classification: Designed for heavy-duty applications, with a working duty classification of M5 or MThis ensures high durability and reliability under frequent and demanding use.

- Usage: Suitable for industrial environments requiring substantial lifting capabilities, such as construction sites, manufacturing facilities, and heavy-duty workshops.

Power Supply

- Voltage: Common power supply options include 380V, 415V, or 660V, depending on regional electrical standards.

- Frequency: Typically operates at 50Hz or 60Hz.

- Phase: Available in three-phase configurations to accommodate various power supply setups.

Special Features

- Anti-Corrosion Coating: Optional coatings for enhanced durability in corrosive or harsh environments.

- Safety Features: Includes overload protection, emergency stop buttons, limit switches, and safety interlocks to ensure safe operation.

- Custom Options: Can be equipped with additional features such as anti-sway systems, integrated lighting, and advanced control systems based on specific needs.

Dimensions and Weight

- Dimensions: Customizable based on span, lifting height, and load capacity requirements. The double girder design provides a sturdy and stable structure.

- Weight: Varies depending on the crane's specifications and materials used. The double girder design typically results in a heavier structure compared to single girder cranes, supporting higher capacities and greater stability.

The BMG Double Girder Semi-Gantry Crane offers a powerful and versatile solution for a range of heavy-duty lifting applications. Its robust design and customizable options make it a valuable asset for facilities requiring high capacity and reliable performance.

Double Girder Semi Gantry Crane 1 Ton to 32 Ton for Sale, Specification Table for Your Reference

Technical Parameter of BMG Double Girder Semi Gantry Crane |

||||||

Capacity |

t |

5 |

10 |

16 |

20 |

32 |

Span |

S(m) |

12~30 |

12~30 |

12~30 |

12~30 |

12~30 |

Lifting height |

m |

6~12 |

6~12 |

6~12 |

6~12 |

6~12 |

Lifting speed |

m/min |

15 |

8.5 |

9 |

2 |

6 |

Trolley speed |

m/min |

32 |

34 |

40.1 |

40 |

37 |

Crane speed |

m/min |

37 |

37 |

40.1 |

40.1 |

38 |

Work duty |

A3~A6 |

A3~A6 |

A3~A6 |

A3~A6 |

A3~A6 |

|

Track type |

P43 |

P43 |

P43 QU70 |

P43 QU70 |

P50 QU80 |

|

Key Features and Benefits of Semi Ganty Cranes

Customization and Flexibility

Specialized Features for Different Industries

- Industry-Specific Add-Ons: Semi-gantry cranes can be equipped with specialized features to cater to specific industry needs. For example, cranes used in the automotive industry might include features for precise positioning of vehicle components, while those in construction might be fitted with heavy-duty hoists for lifting bulky materials.

- Customization Options: Features such as remote controls, advanced hoist systems, and safety enhancements can be added based on the operational demands and environmental conditions of the industry.

Performance Insights

Efficiency in Load Handling

- Optimal Performance: Semi-gantry cranes are designed to handle loads efficiently, providing smooth and reliable lifting operations. Their robust construction and advanced hoisting systems ensure that heavy materials are moved with minimal effort and reduced downtime.

- Enhanced Productivity: By enabling fast and precise load handling, these cranes contribute to increased productivity in various industrial settings. Their ability to manage large or heavy loads efficiently helps streamline operations and improve overall workflow.

Operational Advantages

- Versatility: The ability to adjust span and height makes semi-gantry cranes highly versatile, suitable for a wide range of tasks and environments. This adaptability allows for efficient use in different applications, from light-duty to heavy-duty operations.

- Space Optimization: With their semi-supported design, these cranes require less floor space compared to full gantry systems, making them ideal for environments with limited space or where a full gantry crane would be impractical.

Safety Considerations

Built-in Safety Features

- Safety Mechanisms: Semi-gantry cranes come equipped with various built-in safety features, including overload protection, emergency stop buttons, and safety interlocks. These features are designed to prevent accidents and ensure safe operation.

- Advanced Controls: Many models include advanced control systems that allow for precise operation and monitoring, further enhancing safety by reducing the risk of errors during lifting and maneuvering.

Buying Guide of Semi Gantry Cranes

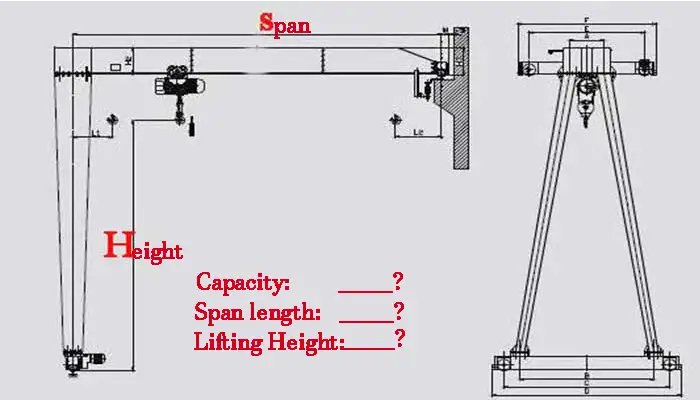

Main parameters required to get your single girder semi gantry crane design and price

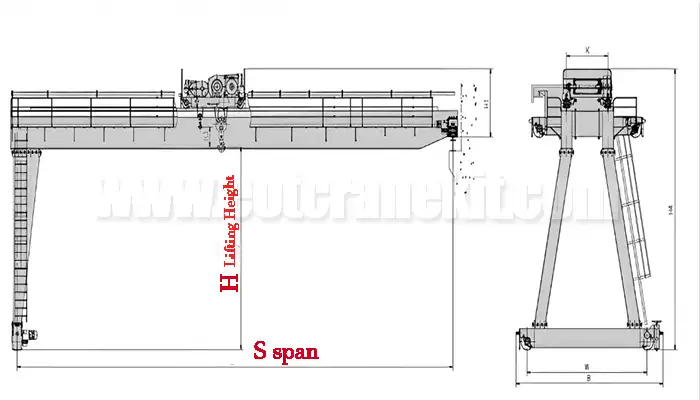

Main parameters required to get your double girder semi gantry crane design and price

Send Us Your Inquiry to Get Your Custom Semi Gantry Crane Price

- Gantry girder design of semi-gantry crane: Single girder / double girder design? With 1 cantilever/ no cantilever?

- Capacity: ____ ,Span:____, Height of Lift:____,Travelling Length:___

- Power supply: 3 phase___Voltage___ Hz

- Operation: Through Pendant/Radio Remote/Cabin Control?

- Application: Industry type: _____, Indoor/Outdoor: ____. Loads: _______

- Size of Existing Rail: ___

Factors to Consider When Choosing

Capacity Requirements

- Assessing Needs: Determine the maximum load your crane will need to handle. This includes not only the heaviest item you expect to lift but also the typical load weight. Choose a crane with a capacity that exceeds your highest anticipated load to ensure safety and longevity.

- Operational Load: Consider the frequency and nature of the loads being handled. For high-frequency operations or consistently heavy loads, select a crane with a higher capacity to avoid overloading and wear.

Space and Environmental Conditions

- Workspace Dimensions: Measure the available space where the crane will be installed, including the height, span, and floor area. Ensure the crane's dimensions fit within these constraints, leaving room for safe operation and maintenance.

- Environmental Factors: Evaluate the environment where the crane will be used. Consider factors such as temperature extremes, humidity, and exposure to chemicals or corrosive substances. Choose a crane with appropriate features or coatings to withstand these conditions.

Customization Needs

- Adjustable Features: Determine if you need adjustable span or lifting height options. Customizable features allow the crane to adapt to various tasks and spatial requirements.

- Special Requirements: Identify any additional features you may need, such as remote controls, specific hoist types, or advanced safety systems. Custom solutions can enhance the crane's performance and suitability for your specific applications.

Choosing the right semi-gantry crane is crucial for optimizing operational efficiency and ensuring safety. Factors such as load capacity, space constraints, and environmental conditions play a significant role in determining the appropriate crane model. Customization options can further enhance the crane's suitability for specific tasks. Additionally, selecting a reputable vendor with reliable support and warranty options can provide long-term benefits and peace of mind.

Your Trusted Semi Gantry Crane Manufacturer & Supplier