Crane for Sale Oman | Overhead Crane & Gantry Crane & Jib Crane

Overhead cranes for sale Oman.Customized industrial cranes, ie., industrial bridge crane, gantry crane & jib crane for warehouse, manufacturing & workshop.

| Crane type | Overhead Crane, Gantry Cranes, Jib Cranes & Monorail Cranes |

| Crane capacity | 1 ton - 100 ton |

| Lifting Height | As your request |

| Crane Span | As customer requirement |

Category: Oman

Your Trusted Overhead Crane Manufacturer & Supplier

A Guide to Bridge Cranes Types & Get Cost-effective Crane Design

Overhead Crane 3 Ton, 5 Ton, 10 Ton 20 Ton up to 100 Ton for Vast Industrial Sectors Oman

Oman, a nation known for its breathtaking landscapes, rich history, and strategic location, has also become a hub for diverse industrial sectors. From the bustling ports along its lengthy coastline to the oil-rich fields and burgeoning manufacturing hubs, Oman's industrial landscape is as varied as its geographical terrain.

Amid this diversity, there's a common thread that binds these industries together – the reliance on overhead cranes. Overhead cranes, with their remarkable lifting capabilities and precision, play a pivotal role in the smooth functioning of various sectors. They are the workhorses that facilitate the movement of heavy loads, ensuring efficiency, safety, and productivity.

What is Overhead Cranes ?

When it comes to the world of heavy lifting and efficient material handling, overhead cranes are the unsung heroes. In this section, we'll explore what overhead cranes are, delve into their various types, and highlight the remarkable versatility that makes them indispensable in Oman's diverse industrial landscape.

What Are Overhead Cranes and Their Types?

At its core, an overhead crane is a complex piece of machinery designed to lift, lower, and transport heavy loads horizontally within a specific area. Unlike traditional cranes that are supported on the ground, overhead cranes are mounted overhead on beams or runways, giving them the advantage of moving freely without occupying floor space.

Types of Overhead Cranes:

- 1. Single Girder Cranes: These cranes have one bridge girder, making them suitable for lighter loads and shorter spans.

- 2. Double Girder Cranes: Featuring two bridge girders, double girder cranes are known for their high load capacity and stability, making them ideal for heavy-duty applications.

- 3. Gantry Cranes: Gantry cranes are versatile and can be used both indoors and outdoors. They are supported on legs or wheels and are often seen at ports and construction sites.

- 4. Jib Cranes: Jib cranes have a horizontal arm that pivots around a vertical post, allowing for precise load positioning in a limited area.

FAQs-How do overhead cranes differ from other lifting equipment?

Overhead cranes are often compared to other lifting equipment like forklifts and mobile cranes. Here's what sets them apart:

- Lifting Capacity: Overhead cranes typically have a higher lifting capacity compared to forklifts, making them suitable for heavy loads.

- Precision: Overhead cranes offer precise load positioning, making them ideal for manufacturing and assembly processes.

- No Floor Obstruction: Unlike forklifts, overhead cranes don't occupy floor space, allowing for efficient use of the workspace.

- Safety: Overhead cranes have excellent safety features, including load limiters and collision avoidance systems.

As we continue our journey through the world of overhead cranes, we'll explore how these impressive machines are tailored to meet the specific needs of various industrial sectors in Oman.

Identifying Your Overhead Crane Needs

Selecting the right overhead crane is a crucial decision that requires a deep understanding of your project's unique requirements. In this section, we'll guide you through the process of assessing your project needs, highlight the key factors to consider, and address the importance of load capacity in crane selection.

Assessing Your Project Requirements

Every project is distinct, and so are its material handling needs. Before diving into the world of overhead cranes, take a step back and assess your project requirements. Here's a step-by-step guide to help you get started:

- Load Capacity: Determine the maximum weight your crane needs to lift. This is a fundamental factor that impacts all other crane specifications.

- Span: Measure the distance between the runways or rails where the crane will operate. This defines the crane's span and influences its stability.

- Lifting Height: Consider how high the crane needs to lift loads. Different projects require different lifting heights, so this is a crucial parameter.

- Environmental Conditions: Take Oman's climate into account. If your project operates in extreme heat, humidity, or dusty conditions, you'll need a crane designed to withstand these elements.

- Duty Cycle: Define how often the crane will be in operation. Is it for occasional use, moderate use, or continuous heavy-duty operation?

- Safety Requirements: Identify any specific safety features or regulations your project must adhere to. Safety is paramount in crane selection.

- Space Constraints: Consider the available workspace. Will a bridge crane fit, or do you need a jib crane due to limited space?

- Material Handling Process: Understand the material handling process. Does it involve precise positioning, continuous movement, or occasional heavy lifts?

Factors to Consider

While assessing your project requirements, keep these critical factors in mind:

- Load Capacity: The crane's ability to safely lift and transport loads is determined by its load capacity. Choosing the right capacity ensures safe operations and prevents accidents.

- Span and Lifting Height: The span and lifting height are interrelated. Ensure they match the dimensions of your workspace and the lifting requirements of your project.

- Environmental Adaptations: Oman's climate can be demanding. Opt for cranes with suitable coatings, weatherproofing, and dust protection to extend their lifespan.

- Duty Cycle: Select a crane that aligns with the expected workload. Heavy-duty projects require robust cranes designed for continuous use.

- Safety Features: Modern overhead cranes come with advanced safety features such as load limiters and collision avoidance systems. Prioritize safety in your selection.

- Maintenance Considerations: Factor in maintenance requirements. Regular inspections and maintenance are essential for crane longevity.

- Cost of Ownership: Assess the total cost of ownership, which includes not only the initial purchase price but also maintenance, energy efficiency, and potential downtime costs.

FAQs-What's the importance of load capacity in crane selection?

Load capacity is a critical factor in overhead crane selection for several reasons:

- Safety: Exceeding the crane's load capacity can lead to accidents and equipment damage. Selecting the right capacity ensures safe operations.

- Efficiency: A crane with the appropriate load capacity is efficient, as it can handle loads without strain, reducing the risk of delays.

- Longevity: Overloading a crane can significantly reduce its lifespan. Choosing the correct load capacity extends the crane's service life.

- Regulatory Compliance: Many safety regulations and standards mandate adhering to load capacity limits. Staying within these limits is crucial for compliance.

Now that you understand the importance of load capacity, let's explore the various types of overhead cranes available in Oman to help you make an informed choice for your specific project needs.

Types of Overhead Cranes Available in Oman

In the world of overhead cranes, variety is the name of the game. Each type of crane is designed with specific features to meet the unique needs of various projects in Oman. In this section, we'll explore the different types of overhead cranes available, including single girder cranes, double girder cranes, gantry cranes, and jib cranes, and address the frequently asked question of which crane type is best suited for small spaces.

- Crane Capacities: Versatile with capacities ranging from 1 to 20 tons.

- Feature: Customizable for different manufacturing processes.

- Industries:Manufacturing, Logistics.

- Commonly Used Applications: Material handling in manufacturing facilities and efficient storage management in logistics and warehousing.

- Tailored for Oman & Typical Project Locations: Designed to enhance manufacturing and logistics operations across Oman's diverse industries.

- Crane Capacities: Typically ranging from 5 to 100 tons.

- Feature: Robust construction, suitable for heavy-duty applications.

- Industries: Oil and Gas, Heavy Industries.

- Commonly Used Applications : Lifting and positioning of equipment, pipes, and heavy materials in oilfields and industrial settings.

- Tailored for Oman & Typical Project Locations: Adapted for the demanding requirements of Oman's oil and gas sector, commonly found in refineries and petrochemical plants.

Single girder overhead crane

Single girder overhead crane specifications: Capacity:3.2 ton to 16 ton, Span: 7.5m to 28.5m,Lifting Height: 6m to 18m,Working Class:A5. Ask for single girder overhead crane price.

Double girder overhead crane

Double girder overhead crane specifications: Capacity:5 ton to 100ton,Span: 10.5m to 31.5m,Lifting Height: 6m to 18m,Working Class:A5- A7. Ask for double girder overhead crane price.

Suspension crane

Underslung overhead crane specifications: Capacity:0.5 ton to 10 ton, Span: 3m to 31.5m, Lifting Height: 6m to 18m,Working Class:A3 to A5. Ask for underrunning crane price & suspension crane price.

KBK crane

Overhead kbk crane specifications: Capacity: 125Kg-5000Kg,Lifting Height: 2.5m-12m,Maximum Span : 3-10m,Working Class: A3. Ask for kbk crane price & kbk light crane price.

Industrial crane

Customized industrial cranes for various industries such as, steel mill, oil & gas, automobile, machinery assembly, mining, general processing, etc.. Ask for industrial overhead crane price.

Process crane

For your specific applications, the process cranes are provided to meet your specific conditions and lifting requirements to save your crane costs.. Ask for process crane price.

Double Girder Cranes vs. Single Girder Cranes

Double Girder Crane

When heavy lifting is required, double girder cranes step into the spotlight. These cranes feature two horizontal girders mounted on parallel runways, offering enhanced stability and load-bearing capacity. Here's why double girder cranes shine in certain scenarios:

- High Load Capacity: Double girder cranes can handle heavy loads, often ranging from 5 to 500 tons or more, making them indispensable in heavy industries.

- Durability: Their robust construction ensures durability and longevity, making them suitable for continuous heavy-duty use.

- Versatility: Double girder cranes are versatile and can be customized to accommodate various applications and lifting needs.

Single Girder Cranes

Single girder cranes are a popular choice for projects with moderate lifting requirements. They are characterized by having a single horizontal beam (the girder) mounted on parallel runways. Here's why single girder cranes are preferred in certain situations:

- Cost-Effective: Single girder cranes are often more budget-friendly than their double girder counterparts, making them an attractive option for cost-conscious projects.

- Compact Design: Their design allows for efficient use of space, making them ideal for facilities with limited headroom.

- Moderate Load Capacity: Single girder cranes are suitable for lifting loads of moderate weight, typically ranging from 1 to 20 tons.

Types of Gantry Cranes for sale in Oman

Gantry cranes are a versatile breed of overhead cranes, known for their adaptability to both indoor and outdoor environments. These cranes are supported on legs or wheels and move along runways on the ground. Here's why gantry cranes are sought after:

- Outdoor Versatility: Gantry cranes can operate in various weather conditions, making them ideal for applications in Oman's ports, construction sites, and shipyards.

- Mobility: The ability to move along the ground provides exceptional flexibility in positioning loads precisely.

- Heavy Load Capacity: Gantry cranes are capable of handling substantial loads, making them valuable in industries like construction and shipping.

Single girder gantry crane for sale Oman

Single girder gantry crane specifications: Capacity: 1ton-20ton, Span Length: 8~30m, Working Class: A3, A4. Ask for single girder gantry crane price in Oman.

L leg single girder gantry crane for sale Oman

L types gantry crane specifications: Capacity 5ton -32ton, Span Length: 18~35m, Working Class: A5, A6.Ask for l leg single beam gantry crane price in Oman.

Truss girder gantry crane for sale Oman

Truss gantry crane specifications: Capacity: 1 ton -50 ton, Span Length: 12~35m, Working Class: A5, A6. Ask for truss gantry crane price in Oman.

Double girder gantry crane for sale Oman

Double girder gantry crane specifications: Capacity: 5 ton - 500 ton, Span Length: 12~35m, Working Class: A5, A6.Ask for double girder gantry crane price in Oman.

Semi gantry crane for sale Oman

Semi-gantry crane specifications: Capacity: 2 ton- 10 ton, Span Length: 8~20m, Working Class: A3, A4.Ask for semi-gantry crane price in Oman.

Portable gantry crane for sale Oman

Portable gantry crane specifications: Capacity:0.25 ton -10ton, Span length: 2~16m,Lifting height : 2~12m, Working class : A2.Ask for small gantry crane price in Oman.

Types of Jib Cranes for Sale in Oman

Jib cranes have a distinct design, consisting of a horizontal arm (the jib) that pivots around a vertical post or column. These cranes are prized for their precision and compact footprint. Here's why jib cranes excel in specific settings:

- Precise Positioning: Jib cranes offer precise load positioning, making them ideal for tasks that require accuracy, such as assembly lines.

- Limited Space: Their compact design is perfect for small spaces or workstations where a full-size overhead crane isn't practical.

- 360-Degree Rotation: Jib cranes can rotate a full 360 degrees, providing excellent coverage within their designated area.

Pillar jib crane Oman

Pillar jib crane specifications-Capacity:0.5 ton -10 ton, Arm length: 3-12m, Lifting height: 3-8m, Rotating : 180, 270, 360 ,Working class: A3.Ask for free standing jib crane price for sale Oman.

Wall mounted jib crane Oman

Wall mounted jib crane specifications-Capacity: 0.25 ton-2 ton, Arm length: 2-6m, Lifting height: 2-6m, Rotating : 180, Working class: A3.Ask for wall mounted jib crane price for sale Oman.

Wall travelling jib crane Oman

Wall-travelling jib crane specifications-Capacity: 0.25 ton-10 ton, Span: 3-10m, Lifting height: 3-8m, Rotating : 180,Working class: A3. Ask for wall travelling jib crane price for sale Oman.

Slewing jib crane Oman

Slewing jib cranes -floor & wall jib cranes- flexible swing or slewing jib arm & rotary crane design, 180, 270 &360 degree rotating jib crane for sale. Ask for slewing jib crane price for sale Oman.

Portable jib crane Oman

Portable jib crane specifications- Capacity: 0.08 ton,1 ton, Lifting Height: 1.5- 3m, Turning Radius: 2m, 3m, Rotation Angle: 360°, Working class: A3.Ask for portable jib crane price for sale Oman.

Process jib crane Oman

Process jib cranes for your specific application to lower your jib crane cost. Contact us to get your customized process jib crane design and your jib crane rate and crane price.

Types of Monorail Hoists and Cranes for Sale in Oman

- Crane Capacities: Variable lifting capacities, typically from 0.5 to 10 tons.

- Feature:Space-saving and efficient for material handling within facilities.

- Industries: Logistics, Manufacturing.

- Commonly Used Applications in Oman: Material handling within distribution centers, manufacturing plants, and production lines.

- Tailored for Oman & Typical Project Locations: Optimized for Oman's logistics and manufacturing operations, improving productivity and space utilization.

European style wire rope monorail hoist Oman

FEM wire rope monorail hoist crane specifications: Capacity: 0.25 ton -50 ton,Ask for electric wire rope monorail hoist and crane price.

Chinese style electric wire rope monorail hoist Oman

Chinese style electric monorail hoist crane specifications: Capacity: 0.25 ton -80 ton,, Ask for Chinese type electric monorail hoist and crane price.

Electric chain monorail hoist Oman

Electric chain hoist specifications: Capacity: 0.25 ton -50 ton,, Ask for electric chain monorail hoist and crane price.

Low headroom monorail hoist Oman

Low headroom hoist specifications: Capacity: 500kg - 80 ton, Ask for low headroom monorail hoist crane price.

Explosion proof monorail hoist Oman

Explosion proof hoist specifications: Capacity: 500kg ton- 50 ton, Ask for explosion proof monorail hoist and crane price.

Air monorail hoist Oman

Air hoist & pneumatic hoist specifications: Capacity:50~32000kg.Ask for air hoist and pneumatic monorail hoist and crane price.

Please note that these capacity ranges are approximate and can vary based on the specific crane models and configurations available in Oman's industrial market.

FAQs-Which crane type is best suited for small spaces?

When working with limited space, jib cranes are often the top choice. Their compact design and ability to rotate 360 degrees make them ideal for small work areas where precision and mobility are essential. However, it's crucial to assess your specific project needs and space constraints to determine the most suitable crane type for your situation. In some cases, single girder cranes may also be a viable option for small spaces due to their efficient use of headroom.

As we continue our journey through the comprehensive guide to overhead cranes in Oman, we'll delve deeper into their applications in various industrial sectors, shedding light on how each type of crane excels in specific environments.

Requirements for overhead crane used in Oman

Overhead cranes used in Oman must meet various requirements to ensure their safe and efficient operation in compliance with local regulations and industry standards. Here are some of the key requirements for overhead cranes used in Oman:

- 1. Compliance with Omani Standards: Overhead cranes in Oman must adhere to the relevant Omani industrial and safety standards. This includes standards set by organizations like the Public Authority for Civil Defense and Ambulance (PACDA) and the Ministry of Manpower.

- 2. Load Capacity: Overhead cranes should be designed and rated for the specific load capacities required by the industry or application. Load capacities must consider the weight and dimensions of the materials and equipment being lifted.

- 3. Safety Features: Overhead cranes must be equipped with essential safety features, including limit switches, emergency stop buttons, overload protection, and safety interlocks to prevent accidents.

- 4. Operator Training: Operators of overhead cranes in Oman must receive proper training and certification to operate the equipment safely and efficiently. Training programs should cover crane operation, load handling, and safety procedures.

- 5. Maintenance and Inspection: Regular maintenance and inspection schedules must be established and followed to ensure the crane's reliability and safety. This includes routine checks of mechanical components, electrical systems, and safety devices.

- 6. Environmental Considerations: Overhead cranes used in environmentally sensitive areas or for projects with environmental impact assessments must comply with specific environmental regulations and guidelines.

- 7. Corrosion Resistance: Due to Oman's coastal regions, cranes must have corrosion-resistant coatings and materials to protect against rust and corrosion from high humidity and salt exposure.

- 8. Heat Resistance: Overhead cranes should be designed to operate effectively in Oman's high-temperature climate. This may involve using heat-resistant materials and cooling systems for critical components.

- 9. Wind Load Calculations: Overhead cranes must be designed to withstand wind loads, especially in areas prone to strong winds. Engineering calculations should determine the crane's wind load capacity and any necessary wind locks.

- 10. Emergency Procedures: Clear and effective emergency procedures and protocols should be established for crane operators and personnel in the event of an emergency or malfunction.

- 11. Documentation and Records: Proper documentation, including equipment manuals, maintenance records, and safety certifications, should be maintained for each overhead crane.

- 12. Compliance with International Standards: Overhead cranes should also meet international standards such as those set by the International Organization for Standardization (ISO) for crane design, safety, and performance.

- 13. Remote Monitoring and Control: In some cases, overhead cranes may benefit from remote monitoring and control systems to improve safety and efficiency, especially in challenging conditions.

- 14. Load Testing: New or modified cranes should undergo load testing to verify their performance and safety before being put into service.

Meeting these requirements ensures the safe and reliable operation of overhead cranes in Oman's industrial and construction sectors. It is essential for crane manufacturers, operators, and project managers to work together to ensure that these requirements are met and that cranes are in compliance with local regulations and industry best practices.

Tailored design for overhead cranes in Oman

Overhead cranes used in Oman may have specific features and considerations due to the country's climate, weather conditions, and national regulations. Here are some special features and considerations for overhead cranes in Oman:

- 1. Corrosion Resistance: Oman's coastal regions are subject to high humidity and salt exposure due to the proximity to the Arabian Sea. Overhead cranes used in these areas may require special corrosion-resistant coatings and materials to protect against rust and corrosion.

- 2. Heat Resistance: Oman experiences high temperatures, especially during the summer months, which can affect the performance of crane components. Overhead cranes in Oman may be equipped with heat-resistant features to ensure safe operation in extreme heat conditions.

- 3. Dust and Sand Protection: Oman's desert regions can lead to the accumulation of dust and sand particles, which can affect the crane's mechanical components. Overhead cranes may be designed with sealed enclosures and protective measures to prevent dust and sand ingress.

- 4. Wind Load Considerations: Oman can experience strong winds, particularly during seasonal weather patterns like the Khareef in Dhofar. Overhead cranes must be designed to withstand wind loads and may have features like wind locks to prevent sway during high winds.

- 5. Safety Regulations: Oman has specific safety regulations and standards governing the operation of cranes and lifting equipment. Overhead cranes used in Oman must comply with these regulations to ensure safe operation. This includes regular inspections and maintenance to meet national safety standards.

- 6. Operator Training: Due to the challenging climate and operational conditions, operators of overhead cranes in Oman may require specialized training to handle the equipment safely in extreme heat, wind, and dust.

- 7. Environmental Considerations: Oman places importance on environmental sustainability. Overhead cranes used in eco-sensitive areas or for projects with environmental impact assessments may need to comply with specific environmental regulations.

- 8. Load Capacity: Overhead cranes in Oman may need to be designed to handle specific load capacities required for industries like oil and gas, heavy industries, and construction, taking into account the weight and dimensions of materials and equipment commonly used in the region.

- 9. Remote Monitoring and Control: To improve safety and operational efficiency, some overhead cranes in Oman may be equipped with remote monitoring and control systems, allowing operators to remotely operate the crane from a safe location, especially in extreme weather conditions.

- 10. Maintenance Scheduling: Due to the harsh operating conditions, regular maintenance and inspection schedules are crucial for overhead cranes in Oman. Preventive maintenance programs are often established to ensure crane reliability and longevity.

These special features and considerations are essential to ensure the safe and reliable operation of overhead cranes in Oman's unique climate and operational environments while complying with national regulations and safety standards. Crane manufacturers and operators in Oman should work together to address these factors and design cranes that can withstand the specific challenges of the region.

Optional features for overhead cranes in Oman

Optional features for overhead cranes in Oman can enhance their functionality, safety, and efficiency, depending on the specific requirements of the industry or application. Here are some optional features commonly considered for overhead cranes:

- 1. Remote Control: Remote control systems allow operators to control the crane from a safe distance, enhancing safety and visibility, especially in challenging operating conditions.

- 2. Variable Frequency Drives (VFD): VFDs provide precise control over crane movements, enabling smoother acceleration and deceleration, reducing wear and tear, and improving energy efficiency.

- 3. Radio Remote Control: Radio remote controls provide flexibility and mobility for crane operators, allowing them to move around freely while controlling crane operations.

- 4. Load Measurement Systems: Load cells and sensors can be integrated to measure the weight of the load being lifted, providing real-time load feedback to the operator and helping prevent overloading.

- 5. Anti-Collision Systems: Anti-collision systems use sensors and software to prevent collisions between cranes or between the crane and other objects, enhancing safety in congested areas.

- 6. Automated Material Handling: Automation features, such as automatic positioning, can improve the precision and speed of material handling operations.

- 7. Camera Systems: Camera systems can be installed on the crane to provide the operator with better visibility, especially when handling large or obstructive loads.

- 8. Heat and Cold Weather Packages: Overhead cranes used in extreme temperatures may benefit from special packages that include insulation, heating, or cooling systems to ensure reliable operation.

- 9. Specialized Hooks and Attachments: Different industries may require specialized hooks, spreader bars, or attachments to handle specific types of loads, such as coils, containers, or fragile materials.

- 10. Maintenance Monitoring Systems: Remote monitoring systems can provide real-time data on the crane's condition and performance, facilitating proactive maintenance and reducing downtime.

- 11. Emergency Backup Systems: Backup power sources, such as generators or uninterruptible power supplies (UPS), can ensure that the crane can be safely lowered in the event of a power outage.

- 12. Environmental Seals: Enhanced seals and gaskets protect critical components from dust, sand, and moisture in harsh environments.

- 13. Energy Efficiency Features: Overhead cranes can be equipped with energy-efficient motors, regenerative braking systems, and LED lighting to reduce energy consumption.

- 14. Customized Paint and Coatings: Customized paint schemes and coatings can provide additional protection against corrosion and harsh weather conditions.

- 15. Wireless Communication: Wireless communication systems enable seamless communication between the crane and other equipment or control centers, improving coordination and efficiency.

- 16. Safety Cameras and Alarms: Additional safety features, such as cameras, alarms, and warning lights, can alert operators to potential hazards and enhance overall safety.

- 17. Smart Control Systems: Smart control systems use advanced algorithms to optimize crane operations, reduce sway, and improve load positioning accuracy.

- 18. Operator Ergonomics: Ergonomically designed operator cabins or control stations enhance operator comfort and reduce fatigue during long shifts.

- 19. Telemetry Systems: Telemetry systems enable remote monitoring and diagnostics of crane performance, facilitating predictive maintenance.

- 20. Customized Software Solutions: Custom software applications can be developed to meet specific project or industry requirements, such as data logging, reporting, or integration with other systems.

The selection of optional features for overhead cranes in Oman should be based on the unique needs of the industry, operating environment, and project specifications. Consulting with crane manufacturers or suppliers with expertise in the Omani market can help determine the most suitable optional features for a particular application.

Overhead Cranes in Oman's Pillar Industrial Sectors

Oman's industrial prowess extends across various sectors, each with its own unique demands. In this section, we'll explore how overhead cranes play a pivotal role in Oman's pillar industrial sectors, including the oil and gas industry, manufacturing, construction, mining and minerals, and logistics and warehousing. We'll also address the frequently asked question of how overhead cranes enhance safety in the oil and gas industry.

Oil and Gas

Industrial Overview: The oil and gas sector is a cornerstone of Oman's economy, involving exploration, production, refining, and petrochemical activities.

Location: Oman's oil and gas operations are located in various regions across the country, including the interior and coastal areas.

Types of Overhead Cranes Used: Double girder bridge cranes, gantry cranes, and explosion-proof cranes.

Typical Crane Capacity: Ranging from 10 to 500 tons.

Typical Functions and Applications: Lifting and positioning of drilling equipment, pipes, and heavy materials in oilfields, refineries, and petrochemical plants.

Tailored for Oman & Typical Project Locations: Customized for the demanding requirements of Oman's oil and gas sector, commonly found in locations such as Sohar, Muscat, and the interior oilfields.

Benefits: Enhanced safety and efficiency in handling heavy equipment and materials in hazardous environments, supporting the nation's critical industry.

Manufacturing

Industrial Overview: The manufacturing sector in Oman encompasses various industries, including food processing, cement, steel, plastics, and textiles.

Location: Manufacturing facilities are distributed across the country, with industrial areas in cities like Muscat and Sohar.

Types of Overhead Cranes Used: Single girder bridge cranes and double girder bridge cranes.

Typical Crane Capacity: Varied, based on specific manufacturing processes, with capacities typically ranging from 1 to 50 tons.

Typical Functions and Applications: Material handling, equipment assembly, and production line support in various manufacturing processes.

Tailored for Oman & Typical Project Locations: Customizable for diverse manufacturing needs across Oman's industrial zones.

Benefits: Improved efficiency, reduced labor costs, and enhanced production processes in Oman's growing manufacturing sector.

Construction

Industrial Overview: The construction sector in Oman is marked by significant infrastructure development, including buildings, roads, bridges, and more.

Location: Construction sites are spread throughout the country, with major projects in Muscat, Salalah, and Sohar.

Types of Overhead Cranes Used: Gantry cranes, mobile cranes (telescopic cranes).

Typical Crane Capacity: Ranging from 5 to 200 tons.

Typical Functions and Applications: Hoisting and placing structural elements, concrete blocks, and materials at construction sites and infrastructure projects.

Tailored for Oman & Typical Project Locations: Designed to meet the specific requirements of Oman's infrastructure projects, including airports, highways, and buildings.

Benefits: Efficient handling of heavy construction materials, speeding up project timelines and ensuring safety.

Mining and Minerals

Industrial Overview: Oman's mining sector involves the extraction and processing of minerals like gypsum, limestone, chromite, and copper.

Location: Mining operations are situated in various regions, including Dhofar and Al Batinah.

Types of Overhead Cranes Used: Double girder bridge cranes and gantry cranes.

Typical Crane Capacity: Ranging from 10 to 100 tons.

Typical Functions and Applications: Ore extraction, material transport within mining facilities, and handling of mined materials.

Tailored for Oman & Typical Project Locations: Designed to handle the demands of Oman's mining and minerals sector, particularly in remote locations.

Benefits: Efficient and safe handling of heavy materials, supporting the extraction and processing of valuable minerals.

Logistics and Warehousing

Industrial Overview: Logistics and warehousing are essential for Oman's trade and distribution, involving the movement and storage of goods.

Location: Logistics and warehousing facilities are located in major cities and industrial areas across Oman.

Types of Overhead Cranes Used: Single girder bridge cranes and monorail cranes.

Typical Crane Capacity: Ranging from 1 to 20 tons, based on warehouse requirements.

Typical Functions and Applications: Material handling, stacking and retrieving pallets, and inventory management in distribution centers and warehouses.

Tailored for Oman & Typical Project Locations: Designed to optimize storage space and streamline logistics operations in Oman's key logistics hubs.

Benefits: Improved storage efficiency, faster goods handling, and enhanced supply chain management.

Ports and Maritime

Industrial Overview: Oman's strategic location along the Arabian Sea has led to a vibrant maritime sector, including port operations and shipping.

Location: Key ports are situated in locations such as Muscat, Sohar, and Salalah.

Types of Overhead Cranes Used: Container cranes, ship-to-shore cranes.

Typical Crane Capacity: Container cranes often have lifting capacities ranging from 40 to 100 tons.

Typical Functions and Applications: Rapid container handling, cargo loading and unloading at ports, and ship maintenance.

Tailored for Oman & Typical Project Locations: Optimized for Oman's strategic ports, ensuring the efficient flow of goods and vessels.

Benefits: Enhanced port efficiency, reduced vessel turnaround times, and support for Oman's maritime trade.

Heavy Industries

Industrial Overview: Heavy industries in Oman include steel production, aluminum smelting, and heavy machinery manufacturing.

Location: Heavy industrial facilities are concentrated in areas like Sohar and Salalah.

Types of Overhead Cranes Used: Heavy-duty double girder bridge cranes.

Typical Crane Capacity: Extremely high lifting capacity, typically exceeding 100 tons.

Typical Functions and Applications: Handling large and heavy materials, steel coil handling, and supporting heavy machinery manufacturing.

Tailored for Oman & Typical Project Locations: Ideal for supporting Oman's heavy industries and manufacturing, especially in industrial zones.

Benefits: Efficient handling of massive materials and components, essential for the production processes of heavy industries.

Aerospace and Aviation

Industrial Overview: Oman's aviation sector involves aircraft maintenance, assembly, and component manufacturing.

Location: Aviation facilities are primarily located in Muscat and Salalah.

Types of Overhead Cranes Used: Gantry cranes, jib cranes.

Typical Crane Capacity: Ranging from 0.5 to 10 tons, based on aviation industry requirements.

Typical Functions and Applications: Aircraft maintenance and repair, engine installation, and assembly of aircraft components.

Tailored for Oman & Typical Project Locations: Designed to meet the specific requirements of Oman's aviation sector, particularly in aviation maintenance centers.

Benefits: Enhanced safety and precision in aircraft maintenance and assembly, ensuring the reliability of aviation operations.

Automotive Manufacturing

Industrial Overview: Oman's automotive manufacturing sector involves the assembly of vehicles and automotive components.

Location: Automotive manufacturing facilities are situated in industrial areas, including Sohar.

Types of Overhead Cranes Used: Single girder bridge cranes.

Typical Crane Capacity: Varied, depending on the automotive manufacturing processes, with capacities typically ranging from 1 to 20 tons.

Typical Functions and Applications: Lifting and positioning vehicle components during assembly processes.

Tailored for Oman & Typical Project Locations: Designed to enhance efficiency and precision in automotive assembly lines.

Benefits: Streamlined production processes, reduced manual labor, and improved vehicle assembly quality.

Renewable Energy

Industrial Overview: Oman is exploring renewable energy sources such as solar and wind power.

Location: Renewable energy projects are distributed across various regions, including remote areas for solar installations.

Types of Overhead Cranes Used: Gantry cranes, telescopic cranes.

Typical Crane Capacity: Varied, based on the specific requirements of renewable energy installations.

Typical Functions and Applications: Supporting the installation and maintenance of renewable energy infrastructure, including solar panels and wind turbines.

Tailored for Oman & Typical Project Locations: Adapted for the demands of Oman's renewable energy initiatives, often in remote desert locations.

Benefits: Efficient handling of renewable energy components, supporting Oman's transition to clean energy sources.

Construction Materials

Industrial Overview: The construction materials sector involves the production and handling of materials like precast concrete elements, steel beams, and cement blocks.

Location: Production facilities are spread across Oman, including industrial areas.

Types of Overhead Cranes Used: Single girder bridge cranes, jib cranes.

Typical Crane Capacity: Varied, based on the specific construction material manufacturing processes.

Typical Functions and Applications: Facilitating the production and handling of construction materials and components.

Tailored for Oman & Typical Project Locations: Customized for the diverse needs of Oman's construction materials sector.

Benefits: Enhanced production processes, efficient handling of materials, and support for the construction industry.

Heavy Equipment Maintenance

Industrial Overview: This sector involves the maintenance and servicing of heavy equipment and machinery used in various industries.

Location: Maintenance facilities are situated in industrial zones and key project locations.

Types of Overhead Cranes Used: Various crane types with capacities suitable for heavy equipment.

Typical Crane Capacity: Varied, depending on the specific maintenance tasks and equipment requirements.

Typical Functions and Applications: Lifting and servicing heavy machinery and equipment components.

Tailored for Oman & Typical Project Locations: Designed to meet the needs of heavy equipment maintenance in Oman's diverse industrial landscape.

Benefits: Efficient equipment maintenance, reduced downtime, and prolonged machinery lifespan.

These sectors represent a diverse range of industries in Oman, each with its unique needs for overhead cranes to enhance efficiency, safety, and productivity.

Sourcing Overhead Cranes: Why Consider China

Choosing the right manufacturer for your overhead crane is a pivotal decision. In this section, we'll explore the advantages of sourcing overhead cranes from China, share success stories of projects in Oman, and address the frequently asked question of what factors to consider when choosing a Chinese crane manufacturer.

Advantages of Chinese Crane Manufacturers

Chinese crane manufacturers have gained global recognition for several compelling reasons:

- Cost-Effectiveness: Chinese manufacturers often offer competitive pricing without compromising on quality. This cost-effectiveness is particularly appealing for projects with budget constraints.

- Customization Options: Chinese manufacturers are known for their flexibility in customizing cranes to meet specific project requirements. Whether you need unique controls or specialized features, they can deliver.

- Quality Assurance: Many Chinese crane manufacturers adhere to international quality standards and certifications, ensuring that their products meet or exceed industry benchmarks.

- Technological Advancements: China has made significant strides in crane technology, integrating advanced features like remote monitoring and automation into their products.

- Wide Range of Products: Chinese manufacturers offer a diverse range of crane types and configurations to suit various applications and industries.

- Global Presence: Many Chinese crane manufacturers have a global presence, providing excellent post-sales support and spare parts availability.

Success Stories in Oman

Oman has witnessed numerous success stories when it comes to sourcing overhead cranes from China:

- Oil and Gas: Several oil and gas projects in Oman have benefited from Chinese overhead cranes. Their reliability, precision, and cost-effectiveness have made them valuable assets in this sector.

- Manufacturing: Manufacturing plants in Oman have increased their efficiency and productivity by adopting Chinese overhead cranes customized to their specific production needs.

- Construction: Construction companies in Oman have successfully used Chinese cranes to handle heavy materials and streamline their operations, contributing to timely project completion.

- Logistics and Warehousing: Warehousing facilities have embraced Chinese cranes for their ability to optimize storage and cargo handling, ensuring smooth logistics operations.

FAQs-What factors should I consider when choosing a Chinese crane manufacturer?

Selecting the right Chinese crane manufacturer involves careful consideration of the following factors:

- Certifications and Compliance: Ensure that the manufacturer adheres to international quality and safety standards. Look for certifications such as ISO and CE.

- Experience: Evaluate the manufacturer's experience in producing cranes for your specific industry and application.

- Reputation: Research the manufacturer's reputation by checking customer reviews and testimonials.

- Customization Capabilities: Assess the manufacturer's ability to tailor cranes to your project's unique requirements.

- Support and Service: Inquire about after-sales support, maintenance, and spare parts availability.

- Cost and Value: Compare pricing with the features and quality offered to ensure you get the best value for your investment.

- Delivery Time: Consider the manufacturer's lead time and delivery capabilities to meet project deadlines.

Choosing a Chinese crane manufacturer with a solid track record and a commitment to quality can significantly contribute to the success of your project in Oman.

Customization and Design Options

When it comes to overhead cranes, one size doesn't fit all. In this section, we'll explore the importance of customization and design options, how cranes can be tailored to Oman's environmental conditions, and the key elements like control systems, hoists, and safety features that can be customized to meet specific project needs. Additionally, we'll address the frequently asked question of whether cranes can be customized for extreme weather conditions in Oman.

Tailoring Cranes to Oman's Environmental Conditions

Oman's climate, characterized by extreme heat, humidity, and dust, presents unique challenges for overhead cranes. Fortunately, Chinese crane manufacturers are adept at customizing cranes to thrive in these conditions:

- - Weatherproofing:Cranes can be equipped with weather-resistant coatings and materials to withstand high temperatures and humidity. This ensures longevity and reliable performance.

- - Dust Protection: Dust can be a significant issue in Oman's industrial settings. Cranes can be designed with sealed components and filtration systems to keep dust out and prevent equipment damage.

- - Heat Resistance:Components subjected to high temperatures can be heat-resistant, ensuring that the crane operates optimally even in scorching conditions.

Control Systems, Hoists, and Safety Features

Customization extends beyond environmental adaptations. Chinese manufacturers offer a range of options for control systems, hoists, and safety features to align with specific project requirements:

- Control Systems: Cranes can be equipped with advanced control systems, including remote operation and automation, to enhance precision and efficiency.

- Hoists: Customizable hoists allow for the lifting of various loads, from delicate materials in the aerospace industry to heavy machinery in manufacturing.

- Safety Features: Cranes can be outfitted with state-of-the-art safety features such as load limiters, anti-sway technology, and collision avoidance systems to ensure a secure working environment.

- Load Monitoring: Load monitoring systems can be integrated to provide real-time data on load capacity and crane performance.

FAQs-Can cranes be customized for extreme weather conditions in Oman?

Yes, overhead cranes can be customized to operate efficiently in Oman's extreme weather conditions. Chinese crane manufacturers have extensive experience in tailoring cranes for diverse environments. Weatherproofing, dust protection, heat resistance, and other environmental adaptations can be incorporated into the crane's design. It's essential to communicate your specific environmental requirements to the manufacturer to ensure the crane is customized to withstand Oman's climatic challenges.

As we progress through this comprehensive guide, the next section will guide you through the purchasing process, from inquiry to delivery, and provide insights into understanding pricing structures and negotiation strategies.

The Purchasing Process

Acquiring the right overhead crane involves a series of steps, from initial inquiry to final delivery. In this section, we'll provide a step-by-step guide to procuring overhead cranes, delve into pricing structures and negotiation strategies, explore import regulations, customs considerations, and address the frequently asked question regarding the common challenges in importing overhead cranes to Oman.

Step-by-Step Guide to Procuring Overhead Cranes

Purchasing an overhead crane is a substantial investment, and a systematic approach is crucial. Here's a step-by-step guide to help you navigate the process:

- Assess Your Needs: Begin by clearly defining your project requirements, including load capacity, span, lifting height, and environmental conditions.

- Research Manufacturers: Identify reputable crane manufacturers, both locally and internationally. Gather information about their products, certifications, and track record.

- Request Quotations: Reach out to selected manufacturers and request quotations based on your project specifications.

- Compare Proposals: Analyze the received proposals, comparing factors such as pricing, customization options, and delivery timelines.

- Visit Facilities (if possible): If feasible, visit the manufacturer's facilities to inspect their production processes and quality control measures.

- Negotiate Terms: Engage in negotiations with the chosen manufacturer to refine the proposal and address any specific requirements or concerns.

- Finalize the Agreement: Once terms are agreed upon, finalize the purchase agreement, including warranties, maintenance terms, and delivery schedules.

- Quality Control Inspection: Prior to shipping, conduct a quality control inspection to ensure the crane meets the agreed-upon specifications.

- Shipping and Import: Arrange for shipping and navigate import regulations and customs requirements. This may include obtaining necessary permits and certifications.

- Installation and Commissioning: Upon arrival, install and commission the crane according to manufacturer guidelines or engage their services for installation.

- Operator Training: Train your personnel in safe crane operation and maintenance practices to ensure efficient and secure usage.

- Regular Maintenance: Implement a maintenance schedule to ensure the crane's longevity and continued safe operation.

Pricing Structures and Negotiation Strategies

Understanding pricing structures and effective negotiation strategies can help you secure the best deal for your overhead crane:

- Fixed Price: Some manufacturers offer fixed pricing, which provides cost predictability. However, ensure that all project requirements are covered in the fixed price.

- Variable Costs: Be aware of variable costs that may arise, such as shipping fees, import duties, and installation charges. Clarify these in your negotiations.

- Bulk Purchases: Consider the potential benefits of bulk purchases if your project requires multiple cranes. Manufacturers may offer discounts for larger orders.

- Long-Term Relationship: Building a long-term relationship with a reputable manufacturer can lead to better pricing and support in the future.

- Warranty and Support: Negotiate warranty terms and post-sales support to protect your investment and ensure quick response to any issues.

Import Regulations and Customs Considerations

Importing overhead cranes to Oman involves adhering to specific regulations and customs considerations:

- Customs Documentation: Prepare all required customs documentation, including invoices, bills of lading, and import permits.

- Customs Duties and Taxes: Be aware of the applicable customs duties and taxes, and ensure compliance with Oman's import regulations.

- Certifications: Verify that the cranes meet Oman's safety and environmental standards and possess the necessary certifications.

- Local Representation: Consider partnering with a local representative or agent who is familiar with Oman's customs procedures and can assist with compliance.

FAQs-What are the common challenges in importing overhead cranes to Oman?

Importing overhead cranes to Oman may present challenges such as:

- Customs Delays: Delays in customs clearance can impact project timelines. Proper documentation and compliance with regulations can mitigate this issue.

- Import Duties: Import duties can add to the overall cost. Ensure you understand the applicable duties and plan your budget accordingly.

- Certification Requirements: Oman may have specific certification and safety standards that must be met. Verify that the cranes comply with these regulations.

- Environmental Compliance: Cranes must adhere to environmental standards, especially in sensitive areas such as oil and gas facilities.

By proactively addressing these challenges and working closely with experienced professionals, you can navigate the import process smoothly and successfully acquire the overhead crane your project requires.

Installation, Training, and Maintenance

The journey of an overhead crane doesn't end with its purchase and delivery. Proper installation, training, and maintenance are essential to ensure safety, longevity, and optimal performance. In this section, we'll emphasize the importance of these aspects, the manufacturer's role in training, offer maintenance tips, and address the frequently asked question about safety inspections in Oman.

The Importance of Proper Installation and Commissioning

The installation of an overhead crane is a critical step that directly impacts its performance and safety. Proper installation includes:

- Foundation Preparation: Ensuring that the crane's supporting structure is solid and level to prevent any structural issues.

- Alignment: Accurately aligning the crane's runways and rails to ensure smooth movement and load-bearing capacity.

- Electrical Setup: Correctly wiring and connecting the crane's electrical components to prevent electrical issues.

- Safety Checks: Thoroughly inspecting all components, including hooks, cables, and safety features, to ensure they are functioning correctly.

- Load Testing: Conducting load tests to verify the crane's lifting capacity and stability.

Manufacturer's Role in Training

The manufacturer plays a crucial role in training personnel to operate and maintain the crane safely and efficiently. Training typically includes:

- Operator Training: Comprehensive training for crane operators to ensure they understand the controls, safety procedures, and load management.

- Maintenance Training: Training for maintenance personnel to perform routine checks, inspections, and basic repairs.

- Safety Training: Emphasizing safety protocols and best practices to prevent accidents and injuries.

- Emergency Procedures: Providing guidance on how to respond to emergencies or equipment failures.

Maintenance Tips for Longevity

Proper maintenance is the key to extending the life of an overhead crane and preventing downtime. Here are maintenance tips to keep in mind:

- Regular Inspections: Perform regular visual inspections of the crane's components, looking for signs of wear, damage, or corrosion.

- Lubrication: Ensure that all moving parts are adequately lubricated to prevent friction and reduce wear.

- Load Testing: Periodically conduct load tests to verify the crane's continued lifting capacity and safety.

- Record-Keeping: Maintain detailed records of maintenance activities, inspections, and any issues encountered.

- Emergency Repairs: Promptly address any identified issues or malfunctions to prevent further damage or accidents.

FAQs-How often should overhead cranes in Oman be inspected for safety?

Safety inspections for overhead cranes in Oman should be conducted at regular intervals to ensure safe and reliable operation. The frequency of inspections can vary based on factors such as the crane's usage, environmental conditions, and manufacturer recommendations. However, a general guideline is to perform inspections:

- Daily: Operators should conduct pre-shift visual inspections to check for any visible issues or anomalies.

- Monthly: More comprehensive inspections should be performed by trained personnel to assess critical components and safety features.

- Annually: An in-depth, thorough inspection should be carried out by qualified inspectors to identify any potential wear or safety concerns.

It's essential to follow manufacturer recommendations and local safety regulations regarding inspection intervals to maintain the crane's safety and compliance.

As we progress through this comprehensive guide, the next section will showcase real-world case studies and success stories of businesses in Oman that have benefited from the use of overhead cranes, highlighting their positive impact on productivity and efficiency.

Case Studies and Success Stories

Seeing is believing, and in this section, we'll bring you real-world case studies and success stories from Oman that demonstrate the tangible impact of overhead cranes on productivity and efficiency. We'll also address frequently asked questions about how businesses in Oman have addressed unique project challenges with overhead cranes.

Real-World Examples in Oman

Example 1- Boosting Efficiency in Manufacturing

A manufacturing facility in Oman faced challenges in handling heavy metal components used in automotive production. By investing in a customized double girder overhead crane with specialized lifting attachments, they significantly improved their production efficiency. The crane's precise control and lifting capacity allowed for seamless handling of heavy components along the assembly line, reducing manual labor and increasing output.

Example 2- Safe and Efficient Operations in the Oil and Gas Sector

An oil and gas project in Oman required reliable material handling solutions for offshore maintenance. They opted for gantry cranes customized for the harsh offshore environment. These cranes provided a safe and efficient means of lifting and positioning equipment during maintenance and repair work on oil platforms. The weather-resistant design and precision controls ensured smooth operations, contributing to increased uptime and safety.

Example 3- Streamlining Logistics and Warehousing

A logistics and warehousing company in Oman faced challenges in optimizing storage and cargo handling. They implemented a fleet of single girder overhead cranes with advanced automation and control systems. These cranes allowed for precise cargo handling, stacking, and retrieval in their high-bay storage facilities. The result was a significant reduction in material handling times, improved inventory management, and enhanced overall logistics efficiency.

Impact on Productivity and Efficiency

The implementation of overhead cranes in these case studies had several noteworthy impacts:

- Increased Productivity: Overhead cranes streamlined material handling processes, reducing manual labor and significantly increasing productivity across various industries.

- Enhanced Safety: Cranes provided precise load control and minimized the risk of accidents, ensuring a safer working environment.

- Efficient Use of Space: Overhead cranes optimized storage and workspace, making the most of available real estate.

- Cost Savings: By reducing manual labor and improving operational efficiency, businesses in Oman achieved substantial cost savings over time.

FAQs-How have businesses in Oman addressed unique project challenges with overhead cranes?

Businesses in Oman have addressed unique project challenges with overhead cranes by:

- 1. Customization: Tailoring crane designs to suit specific project needs, whether in extreme weather conditions, limited space, or challenging environments.

- 2. Advanced Technology: Leveraging advanced crane control systems, automation, and safety features to address complex project requirements.

- 3. Increased Efficiency: Using overhead cranes to streamline material handling, resulting in increased efficiency and reduced project timelines.

- 4. Improved Safety: Prioritizing safety by choosing cranes with precise load control and safety features to protect both personnel and equipment.

Conclusion and Final Thoughts

In this comprehensive guide, we've embarked on a journey to explore overhead cranes and their applications in various industrial sectors in Oman. Now, it's time to recap key takeaways, emphasize the importance of making informed decisions, highlight why China is a top choice for overhead cranes in Oman, and address frequently asked questions about getting started with selecting an overhead crane for your project in Oman.

Key Takeaways

Throughout this guide, we've covered crucial aspects of overhead cranes, including:

- Understanding the different types of overhead cranes and their applications.

- Identifying your project's specific requirements and factors to consider in crane selection.

- The types of overhead cranes available in Oman, along with their features and benefits.

- The advantages of sourcing overhead cranes from China, including cost-effectiveness, customization, and quality.

- How to evaluate and select a reputable Chinese crane manufacturer.

- The importance of customization and design options tailored to Oman's environmental conditions.

- The step-by-step process of procuring and importing overhead cranes to Oman.

- The significance of proper installation, training, and maintenance for crane longevity and safety.

- Real-world case studies demonstrating the positive impact of overhead cranes on productivity and efficiency.

The advantages of considering Chinese overhead crane manufacturers for your project needs in Oman.

Making Informed Decisions

Selecting the right overhead crane for your project in Oman is a decision that requires careful consideration. By following the steps outlined in this guide and conducting thorough research, you can make informed decisions that align with your project's specific needs, budget, and safety requirements.

Why China Is a Top Choice for Overhead Cranes in Oman

China has emerged as a top choice for overhead cranes in Oman due to several compelling reasons:

- Cost-Effectiveness: Chinese manufacturers offer competitive pricing without compromising on quality.

- Customization Options: Chinese manufacturers are flexible in customizing cranes to meet specific project requirements.

- Quality Assurance: Many Chinese crane manufacturers adhere to international quality standards and certifications.

- Technological Advancements: China has integrated advanced features like remote monitoring and automation into their crane technology.

- Wide Range of Products: Chinese manufacturers offer a diverse range of crane types to suit various applications.

- Global Presence: Many Chinese crane manufacturers provide excellent post-sales support and spare parts availability.

FAQs-How can I get started with selecting an overhead crane for my project in Oman?

To get started with selecting an overhead crane for your project in Oman:

- Assess Your Needs: Clearly define your project requirements, including load capacity, span, lifting height, and environmental conditions.

- Research Manufacturers: Identify reputable crane manufacturers, both locally and internationally.

- Request Quotations: Reach out to manufacturers with your project specifications and request quotations.

- Evaluate Proposals: Analyze the proposals received, considering pricing, customization options, and delivery timelines.

- Engage in Negotiations: Work closely with the chosen manufacturer to refine the proposal and address specific requirements.

- Ensure Compliance: Navigate import regulations and customs requirements while ensuring compliance with safety and environmental standards.

- Install, Train, and Maintain: Properly install the crane, train personnel, and implement a maintenance schedule to ensure longevity and safety.

By following these steps and seeking guidance from experienced professionals, you can successfully select and implement the right overhead crane for your project in Oman.

In conclusion, overhead cranes are versatile tools that enhance productivity and safety across various industrial sectors in Oman. By considering Chinese overhead crane manufacturers, you can access cost-effective, high-quality solutions tailored to your project's unique needs. We hope this comprehensive guide has provided valuable insights to aid you in making informed decisions and achieving success in your endeavors.

Glossary of Overhead Crane Terminology

- Bridge Crane: A type of overhead crane that travels horizontally along elevated runways, also known as girders or bridges.

- Gantry Crane: A type of crane similar to a bridge crane but with legs or vertical supports that move on wheels or along tracks.

- Jib Crane: A crane with a horizontal arm (jib) that supports a hoist and can rotate to move loads within a specific area.

- Hoist: The device used for lifting and lowering loads. It is typically suspended from the crane's trolley.

- Trolley: The mechanism that moves the hoist horizontally along the bridge or jib of the crane.

- Load Capacity: The maximum weight a crane can safely lift.

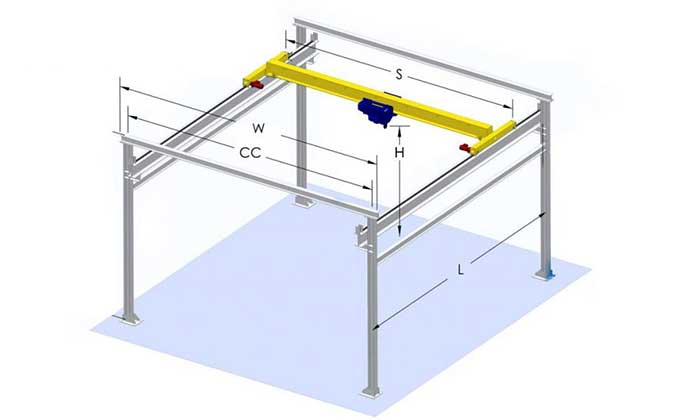

- Span: The horizontal distance between the runway rails or the supporting structure for bridge and gantry cranes.

- Lifting Height: The maximum vertical distance a crane can lift a load.

- Control System: The technology and devices used to operate and control the crane, often including remote control options.

Contact us to get your customized overhead crane for sale in Oman

We are interested in procuring an overhead crane for our project in Oman. Please find the specifications below:

- Types of Overhead Crane Required: ___ [Specify crane design, bridge crane, gantry crane or monorail cranes]

- Load Capacity:___ [Specify load capacity]

- Span: ___[Specify span]

- Lifting Height:___ [Specify lifting height]

- Control System:___ [Specify control system requirements]

- Environmental Conditions: ___ [Specify environmental conditions the crane will operate in]

FAQs-Where can I find comprehensive information on Oman's crane regulations?

Comprehensive information on Oman's crane regulations can typically be obtained from the following sources:

- 1. Oman Ministry of Commerce, Industry, and Investment Promotion: The ministry's official website may provide details on industrial regulations, safety standards, and certifications related to crane operation.

- 2. Oman Chamber of Commerce and Industry: Local chambers of commerce often offer guidance and resources on regulatory compliance for various industries, including crane operation.

- 3. Professional Associations: Industry-specific associations and organizations in Oman may offer resources and guidance related to crane regulations.

- 4. Local Authorities: Contact local authorities or government agencies responsible for industrial safety and regulations in Oman for specific information and guidelines.

It's essential to stay informed about the latest regulations and safety standards when operating overhead cranes in Oman to ensure compliance and the safety of your operations.

Main Projects

Related Products

Latest project

32/5 Ton Overhead Crane Sale in India: Case Study

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch