Overhead Crane Winch Trolley & Gantry Crane Winch Trolley

European crane winch, compact European open winch trolley design, fast, safe & reliable for FEM & DIN open winch cranes, double girder overhead & gantry cranes, etc.

| Part type | Open winch trolley |

| Capacity of open winch | 10 ton - 500 ton |

| Lifting Height | Customized |

| Working Class | M5 |

Category: Crane Kit Parts

Your Trusted Overhead Crane Manufacturer & Supplier

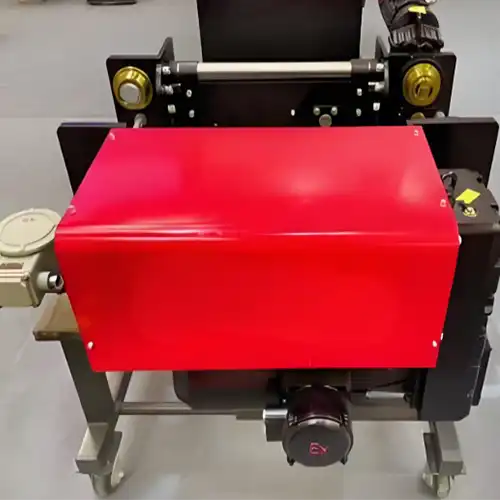

European Open Winch, Processed Electric Crane Winch Trolley

European crane winch is a process crane components for heavy duty double girder overhead travelling cranes and overhead gantry cranes with features of fast, safe and reliable. The European winch trolleys are tailored to meet the specific requirements of your application and process cranes. The process winch trolleys are vary versatile and applicable to a variety of industrial applications. Contact to get customized European standard crane winch.

Sample pictures of European style of crane winch & European crane winch, heavy duty winch crane wincth

European Crane Winch Parameters

The crane winch are designed for process cranes for heavy duty industrial applications. To meet the various industrial applications, the modular crane winch can be combined with featured parts and components to meet particular applications such as the turn over trolley, anti-sway device, automatic positioning device, monitoring , or remote diagnostic devices, and various below-the-hook devices etc. The main specifications of European electric winch trolley are for your reference. For processed crane winch, please confirm with our engineer.

Main Parameters of European Crane Winch

- Capacity of European crane winch :10 ton - 500 ton

- Lifting height of European crane winch: As your request

- Working Duty of European crane winch :M5

- Crane traveling of European crane winch:3-30 m/min

- Process crane winch are available for your particular industrial needs and applications.

Of top configurations, the European style open winch crane trolley are consisted of Schneider electric elements, ABM / SEW/Siemens triple gear motor, with three in one design including motor, gear box and brake, high strength galvanized wire rope, self-adjusted disk brake, hard tooth reducer, programmable lifting limit switch, and so on.

Advantages of European Crane Winch

Adopting advanced technology and designed on the base of international standards of FEM (Europe), DIN (Germany), ISO(International), the European style open winch crane trolley are with the features of strong rigidity, light dead weight, outstanding winch structure, etc.

- Process crane winch meet your particular needs - Process open winch ,ergonomic design, various configurations , wide lifting capacities , to meet your particular application needs no matter what industrial sector you are in.

- Compact structure, light weight, small volume - More compact open winch structure and layout, the crane winch has high driving efficiency, low noise, low crane height and low dead weight, which reduces the overall dimensions of the overhead open crane.

- Best space utilization, lower facility production costs- With light weight and low headroom design, the crane winch can operate the load lifting on end carriages of trolley frame on both side, offering large space for load handling vertically and horizontally in space limited workshops which may save your facility production cost.

- Convenient operation -Modular design with all the winch trolley components such as, motor, brake and gearbox are in a compact arrangement offering clear interfaces making crane winch assembly and maintenance ease and simple.

- Strong performance - Stabilized lifting systems with multi- groove rope drums for wire rope are designed for lifting load with capacity up to 500 ton.

- High operating reliability -With various baking systems including rope drum brake, second disc or double-jaw brake and other safety devices, the open crane winch trolley are applicable for hot ladle handling with high safety and reliability.

- Make the best value of your investment - The European style of crane winch helps to improve your productivity with low maintenance rate and maintenance cost, enjoying durable working life, which will help you make the best value of your crane investment and at the same time to create more value for your business.

Main Parts and Components of European Style Open Winch Trolley for Heavy Duty Material Handling

Main Parts of European style open winch: Hoisting motor, Hoisting brake, Hoisting speedreducer gear box,

Main parts and components of European style heavy duty open winch: Wire rope drum, Wire rope, Electrical Control, Hook

Squirrel-Cage Asynchronous Motor

The European-style Open Winch Trolley is equipped with a squirrel-cage asynchronous motor, known for its robust performance and reliability. This type of motor is designed to operate efficiently with a synchronous speed of up to 3,000 revolutions per minute (rpm). Its construction ensures consistent performance across various industrial applications, making it a dependable choice for demanding environments.

- Variable-Frequency Stepless Speed Regulation: One of the key features of this hoisting motor is its variable-frequency drive (VFD), which allows for precise and stepless speed regulation. This technology enables smooth adjustments to the hoisting speed, offering enhanced operational flexibility. By providing variable speed control, the motor supports a wide range of lifting tasks, improving overall efficiency and adaptability.

- Heavy Duty System: The motor is designed to handle heavy-duty applications with a load duration rate of 50%ED (duty cycle). This means it is built to perform reliably under substantial loads, making it suitable for high-demand industrial operations. Its heavy-duty system ensures that it can withstand the stresses of frequent and intense use while maintaining operational efficiency.

- Insulation and Protection: To ensure durability and performance in challenging environments, the motor features F class insulation. This type of insulation is designed to withstand high temperatures and prevent overheating. Additionally, the motor has an IP55 protection rating, which means it is resistant to dust and water ingress. This makes it suitable for use in harsh conditions, where exposure to elements could otherwise impact its functionality.

In summary, the European-style Open Winch Trolley's hoisting motor combines advanced features and robust construction to deliver high performance and reliability. With a squirrel-cage asynchronous motor, variable-frequency speed control, and a heavy-duty system, it is designed to meet the demands of various industrial applications. Its F class insulation and IP55 protection rating further enhance its suitability for challenging operating environments, ensuring long-term durability and consistent performance.

Hoisting Brake

- Electromagnetic Disk Brake:The hoisting brake of the European-style Open Winch Trolley features an advanced electromagnetic disk brake system. This type of brake is known for its precision and reliability, offering effective braking performance under various operating conditions. The brake's design ensures synchronized operation with the motor, contributing to overall system efficiency.

- Design and Safety Features: The brake is a normally-closed type, integrated with the motor to ensure optimal synchronization. It provides a safety brake moment that is at least 1.8 times the required level, effectively preventing hook slippage. This high safety margin enhances the reliability of the braking system, making it suitable for critical lifting applications.

- Durability and Protection: The brake is designed with a high level of airtightness, making it resistant to dust and contaminants. This feature is crucial for maintaining brake performance and longevity in demanding environments. The system is built to handle heavy-duty use, ensuring reliable operation even under strenuous conditions.

- Friction and Environmental Considerations:The brake incorporates a large friction contact area, which allows for adjustable braking moments. This design feature enables fine-tuning of the braking force to meet specific operational requirements. Additionally, the brake uses asbestos-free friction sheets, making it an environmentally-friendly choice that complies with modern safety and environmental standards.

- Brake Block Life: The lifespan of the brake block is a significant consideration in its design. Under normal usage conditions, the brake block is rated for not less than 1,000,000 cycles, providing long-term reliability and reducing the need for frequent replacements. In emergency braking situations, the brake block can withstand at least 500 cycles, ensuring effective performance when it is most needed.

The European-style Open Winch Trolley is equipped with a state-of-the-art electromagnetic disk brake that combines advanced design with robust safety features. Its integration with the motor ensures precise synchronization, while the 1.8-fold safety brake moment prevents slippage. With high airtightness, dustproof construction, and environmentally-friendly friction materials, this brake system is built to deliver reliable performance and longevity. Its impressive lifespan of up to 1,000,000 cycles in regular use further underscores its durability and efficiency.

Hoisting Reducer Specifications

Lightweight and Sealed Design:The hoisting speed reducer of the European-style Open Winch Trolley is engineered to be both lightweight and highly durable. Its design emphasizes a low dead weight, which contributes to the overall efficiency of the winch system by reducing the load on other components. Additionally, the reducer features excellent sealing, ensuring protection against dust and moisture ingress. This enhances its performance and longevity, especially in demanding industrial environments.

Gear Mechanism:The speed reducer utilizes a helical gear mechanism with a hard tooth surface. Helical gears are known for their smooth and efficient power transmission, which minimizes noise and vibration during operation. The hard tooth surface ensures increased durability and resistance to wear, contributing to reliable and long-term performance. This gear configuration is ideal for handling the high stresses and operational demands of industrial hoisting applications.

In summary, the hoisting speed reducer of the European-style Open Winch Trolley combines a lightweight, sealed design with a robust helical gear mechanism. Its low dead weight and effective sealing provide enhanced operational efficiency and durability. The use of helical gears with a hard tooth surface ensures smooth power transmission and long-lasting performance, making it a reliable component for demanding lifting tasks.

Hoisting Motor

- Squirrel-Cage Asynchronous Motor :The hoisting motor in the European-style winch trolley is a squirrel-cage asynchronous type. This motor is designed for high efficiency and reliability, with a synchronous speed that can reach up to 3,000 revolutions per minute. The squirrel-cage design enhances durability and performance, making it suitable for demanding industrial applications.

- Variable-Frequency Stepless Speed Regulation:The motor features variable-frequency stepless speed regulation. This allows for precise control over the motor's speed, enabling smooth and gradual adjustments to match the specific requirements of various lifting tasks. The ability to regulate speed without discrete steps ensures optimal performance and flexibility during operation.

- Heavy Duty System:Designed for heavy-duty use, the hoisting motor supports a load duration rate of 50% ED (duty cycle). This means the motor is built to handle continuous operation with high loads while maintaining efficiency and reliability. Its heavy-duty construction ensures it can withstand the rigors of frequent and intense use.

- Insulation and Protection:The motor is equipped with F-class insulation, providing high-temperature resistance and ensuring reliable operation in demanding environments. Additionally, it has an IP55 protection rating, which means it is protected against dust ingress and water jets from any direction. This level of protection enhances the motor's durability and suitability for harsh industrial conditions.

In summary, the hoisting motor of the European-style winch trolley is a high-performance squirrel-cage asynchronous motor with a synchronous speed of up to 3,000 revolutions per minute. It features variable-frequency stepless speed regulation for precise control, a heavy-duty system with a 50% ED load duration rate, and robust F-class insulation with an IP55 protection rating. These specifications ensure the motor's efficiency, durability, and suitability for demanding lifting operations.

Hoisting Brake

- Electromagnetic Disk Brake:The hoisting brake for the European-style Open Winch Trolley is a state-of-the-art electromagnetic disk brake. This brake system is designed to integrate seamlessly with the motor, offering excellent synchronization for reliable operation. Its electromagnetic nature ensures precise and responsive braking performance.

- Safety and Synchronization:This brake features a normally-closed design, which enhances its safety by ensuring that it remains engaged when not actively in use. The system is engineered to provide a brake moment that is at least 1.8 times the required safety margin. This robust braking force effectively prevents hook slippage, ensuring secure and stable lifting operations.

- Durability and Protection:The brake system is built to withstand harsh conditions with its highly airtight and dustproof construction. This design protects the internal components from dust and environmental contaminants, thereby extending the lifespan of the brake. The heavy-duty system is capable of handling demanding applications, making it suitable for industrial environments.

- Friction and Environmental Considerations:The brake includes a large friction contact area, which allows for adjustable braking moments to suit various operational needs. Additionally, it utilizes asbestos-free friction materials, aligning with modern environmental and safety standards. This choice not only enhances safety but also promotes eco-friendliness.

- Brake Block Life:The brake block is designed for exceptional durability. Under regular usage, it has a lifespan of no less than 1,000,000 cycles, ensuring long-term reliability and reducing maintenance frequency. In emergency braking situations, the brake block is effective for at least 500 cycles, providing dependable performance in critical moments.

In summary, the hoisting brake of the European-style Open Winch Trolley combines advanced features with robust safety and durability. Its electromagnetic disk design, high safety margin, and heavy-duty construction make it well-suited for industrial applications. With an airtight, dustproof design, and environmentally-friendly materials, the brake system offers reliable performance and longevity, ensuring secure and efficient lifting operations.

Hoisting Speed Reducer

- Lightweight and Sealed Construction:The hoisting speed reducer of the European-style Open Winch Trolley is designed to be both lightweight and highly efficient. Its low dead weight contributes to the overall system's efficiency by reducing the strain on other components. Additionally, the reducer is constructed with excellent airtightness to protect against dust and moisture, which enhances its reliability and durability in challenging industrial environments.

- Helical Gear Mechanism:The speed reducer utilizes a helical gear mechanism with a hard tooth surface. Helical gears are known for their smooth, quiet operation and efficient power transmission. The hard tooth surface increases the reducer's resistance to wear and extends its operational lifespan, ensuring reliable performance even under high-stress conditions.

In summary, the hoisting speed reducer of the European-style Open Winch Trolley features a lightweight and well-sealed design for improved efficiency and durability. The helical gear mechanism with a hard tooth surface ensures smooth and reliable power transmission, making it a robust component for demanding lifting applications.

Cable Management Features

- Minimum Cable Coil Requirement:To ensure safe and reliable operation, the winch trolley is designed so that when the hook is at its lowest point, at least two coils of the steel wire rope remain wound around the drum. This design prevents the cable from becoming loose and ensures stable operation throughout the lifting process.

- Ductile Cast Iron Wire Guide:The winch features a wire guide made from ductile cast iron. This material is chosen for its durability and resistance to wear, making it ideal for heavy-duty applications. The wire guide ensures smooth and consistent routing of the cable, reducing the risk of cable damage and extending the lifespan of both the cable and the winch system.

- Anti-Loosening Rope Equipment:An anti-loosening device, consisting of a spring pinch roll, is integrated into the winch trolley. This mechanism effectively prevents the steel wire rope from slipping out of the groove. The spring pinch roll ensures that the cable remains securely in place during operation, enhancing safety and reducing the likelihood of operational disruptions.

In summary, the European-style Open Winch Trolley incorporates essential cable management features to ensure reliable and safe operation. The requirement for at least two coils of cable wire around the drum at the lowest hook point prevents cable slippage. The ductile cast iron wire guide offers durability and wear resistance, while the anti-loosening rope equipment with a spring pinch roll keeps the cable securely in place. These features collectively contribute to the system's efficiency and safety.

Key Safety and Durability Features

- Minimum Cable Coil Requirement:When the hook is at its lowest point, the winch is designed to ensure that at least two coils of the steel wire rope remain wound around the drum. This feature is crucial for maintaining the stability and safety of the hoisting system, preventing the cable from becoming loose or unspooled during operation.

- Ductile Cast Iron Wire Guide:The winch trolley incorporates a wire guide made from ductile cast iron. This material is selected for its heavy-duty capabilities and excellent wear resistance. The use of ductile cast iron ensures that the wire guide can withstand the stresses of frequent use and abrasive conditions, contributing to the longevity and reliability of the winch system.

- Anti-Loosening Rope Equipment:To prevent the steel wire rope from slipping out of the groove, the winch is equipped with an anti-loosening device that consists of a spring pinch roll. This mechanism effectively keeps the cable securely in place, reducing the risk of operational issues and enhancing safety by ensuring the rope remains properly aligned during lifting operations.

In summary, the European-style Open Winch Trolley is designed with critical safety and durability features. The requirement for at least two coils of steel wire rope around the drum when the hook is at its lowest point ensures operational stability. The ductile cast iron wire guide offers heavy-duty performance and wear resistance, while the anti-loosening rope equipment with a spring pinch roll effectively prevents the cable from slipping out of place. These features collectively enhance the reliability and safety of the hoisting system.

Wire Rope

- High Strength Steel Wire Rope:The winch trolley is equipped with high-strength steel wire rope, designed to meet the rigorous demands of industrial lifting applications. This cable wire features a breaking force of up to 1960 N/mm², ensuring it can handle substantial loads with high reliability. The superior strength of the wire rope contributes to the overall safety and performance of the hoisting system, making it suitable for demanding and heavy-duty operations.In summary, the European-style Open Winch Trolley uses high-strength steel wire rope with an impressive breaking force of up to 1960 N/mm². This robust cable wire ensures reliable performance under heavy loads, enhancing the safety and efficiency of the winch system in various industrial applications.

- Protection and Safety:The electrical control system of the European-style Open Winch Trolley is designed with an IP55 protection rating. This level of protection ensures that the control system is highly resistant to dust ingress and water jets from any direction, making it suitable for use in challenging and harsh industrial environments. This protection enhances the durability and reliability of the electrical components, reducing the risk of damage and ensuring consistent performance.

- Connector:The control system features an aviation plug, known for its robust construction and reliable connection. Aviation plugs are designed to withstand high levels of vibration and environmental stress, providing secure and stable electrical connections. This type of connector ensures that the electrical control system operates smoothly and effectively, even in demanding conditions.

In summary, the electrical control system of the European-style Open Winch Trolley is equipped with an IP55 protection rating, offering excellent resistance to dust and water. The inclusion of an aviation plug ensures secure and reliable electrical connections, contributing to the system's overall durability and performance in industrial settings.

Hook

- Forging Hook :The hook of the European-style Open Winch Trolley is made from 34CrMoV steel, which is hardened and tempered to enhance its strength and durability. This high-quality material complies with the DIN17200 standard, ensuring the hook meets rigorous industrial requirements for load-bearing and safety.

- Life-Cycle Lubricating Bearing:The hook is equipped with a life-cycle lubricating antifriction bearing that allows for 360-degree rotation. This design feature ensures smooth operation and reduces friction, enhancing the hook's performance and extending its service life. The bearing's continuous lubrication minimizes maintenance needs and ensures reliable performance during lifting operations.

- Safety Buckle:To enhance safety, the hook is fitted with a safety buckle that prevents accidental unhooking. This feature secures the load and reduces the risk of incidents during lifting and handling, contributing to a safer working environment.

In summary, the hook of the European-style Open Winch Trolley is constructed from 34CrMoV hardened and tempered steel, conforming to DIN17200 standards for robust load-bearing capacity. It features a life-cycle lubricating antifriction bearing that allows 360-degree rotation, ensuring smooth and efficient operation. The integrated safety buckle provides additional security by preventing unhooking, enhancing overall safety during use.

European style open winch for double girder crane

Builtup hoisting wich for heavy duty material handling

European style with compact desigh, and low headroom design

Wrie rope drum customized to meet your open winch design

Gearbox for your reference

Application of European Style Open Winch Crane

The process crane winch are applicable for process cranes in the double girder overhead travelling cranes designs and gantry crane designs for heavy duty material handling with working class of A7, A8 and the lifting capacity from 10 ton, 50 ton, 80 ton, 100 ton up to 200ton & 500 ton,etc.

Below-the-Hook Devices for European Style Winch Crane & Open Winch Crane

The processed European crane winches can be used on various types of double girder cranes, equipped with different under-the-hook devices, and the FEM open winch cranes are can be used for various of heavy duty material handling and applications with high safety, reliability, stability and efficiency.

The process winch cranes are widely adopted in various industrial applications such as in steel and metal processing, paper-making , power energy industry, petrochemical, and metallurgical industry, and others, etc.

Winch open crabs or crane winch are configured and processed individually from dependable system components that also satisfy the most insistent quality prerequisites. Designed for heavy loads handling , the European style crane winches are processed to meet your specific demands of applications and requirements with capacity from 5 ton to 500 ton.

Tailored Open Winch, Cost-effective European Open Winch and Crane Winch Trolley Solution

With advanced techniques and expertise, we are ready to provide you the tailored crane winch for your processed open winch crane which will meet you lifting requirement and specific industrial setup satisfactorily. Send us an inquiry on European style crane winch &open winch for your process crane.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch