Custom Crane| Custom Built Overhead Crane For Special Needs

Custom built overhead cranes system for special needs for industries of any sizes - custom overhead crane, custom gantry crane & custom jib crane, etc.

Category: Hazardous Environment Cranes

Your Trusted Overhead Crane Manufacturer & Supplier

Custom Crane For Your Special Needs

Special Built Overhead Crane Systems Meet Your Lifting Requires & Conditions

Custom crane and custom built cranes system for your particular needs for industries of any sizes, custom overhead crane, custom gantry crane & custom jib crane are all available.

There are numerous advantages to purchasing a custom crane system rather than standard overhead cranes. Our custom built overhead crane system and gantry crane systems are designed to meet the specific needs of our customers. Although custom crane systems have a longer lead time, you may rest assured that they will fit where they were supposed to go.

A standard crane may not always be the best option.

If a conventional crane won't work for your application, a custom crane may be is your solution. Our crane engineers will take great pleasure in being able to give customers the crane that best suits the needs of their application. Cranes built based on your particular application conditions and lifting requirement with unique features and advantages are maybe the best solution for you.

To find the right crane, consider the speed, capacity, lift, and options that will make it the best fit for your project.

Many times, a minor change to a standard configuration is all that is required to significantly improve the crane's performance for a specific job. Other times, redesigning the entire handling system has proven to be the best way to achieve the desired results.

Capabilities for design and manufacture custom cranes

Since 1984, we've been designing, engineering, manufacturing, and installing jib cranes & overhead bridge crane , and gantry crane systems for overhead 30 years. With our own staff of Engineers, specialty applications are common for our experts.

Known for our extensive product line and engineering skills, we can provide:

- Custom jib cranes

- Wall traveling crane

- Overhead cranes

- Custom industrial cranes

- Goliath Crane & Gantry Crane

- KBK track systems

- Automated and Semi-Automated Cranes

- Freestanding overhead cranes

We have the expertise to design almost any type of custom crane crane system to meet the specific needs of the end user. We can produce general use overhead crane and hazardous environment cranes which can use spark-resistant materials utilizing bronze bridge and trolley wheels and spark resistant and explosion-proof electrical components for use in hazardous environments.

We have practical experience in crane applications and conditions that call for specialized material handling crane solution. For instance, we are able to build cranes for heavy weights, severe weather, precise measurements, and high duty cycles. For information on some specific projects , please feel free to contact us.

Your Trusted Overhead Crane Manufacturer & Supplier

CUSTOM CRANES FOR ALL YOUR NEEDS AND APPLICATIONS

Overhead cranes & bridge cranes

- Capacity:1/2 Ton - 100+ Tons Coverage:Square or Rectangular

- Bridge overhead cranes are built with parallel runways and a bridge beam that spans the gap between them. Between the runways, a lifting hoist and its travelling trolley are mounted on the main bridge girder for heavy loads handling. Bridge overhead cranes are available in single girder design, double girder design, box girder design, or I-beam girder systems and can be building supported, ceiling mounted, or freestanding.

Gantry Cranes

- Capacity:1/4 Ton - 10 Tons, 1 Ton -550 Ton Coverage:Rectangular

- Gantry cranes are made up of two legs connected by a rail that spans the width of the crane. Gantry cranes can be fixed or portable, and they can be used both outdoors and indoors.

- Full gantry cranes with single or double girders, lightweight portable gantry cranes, and adjustable gantry cranes are all options.

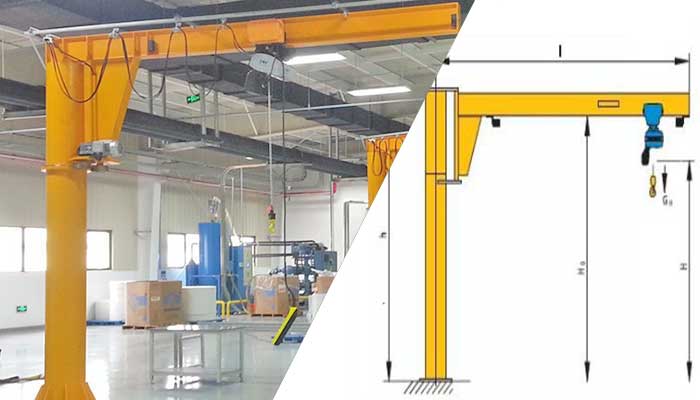

Jib Cranes

- Capacity:1/4 Ton - 16 Tons: Coverage:Circular

- Jib or boom cranes, as well as cantilever cranes, are built with a vertical support and a horizontal lifting arm. Jib cranes are designed to lift and transport materials around the support structure 360 degrees or 200 degrees.

- Depending on your needs and application, select from wall-mounted, freestanding, tie rod, or articulating models.

KBK Crane & Monorails

- Capacity:1/2 Ton - 32 Tons Coverage:Linear

- Monorail systems are made comprised of an enclosed track and an I-beam for support. Monorail cranes don't have moveable girders, in contrast to bridge cranes. Instead, the monorail hoist is moved along the I-beam by the trolley.

- Linear tracks, u-shaped tracks, circular tracks, or a combination of tracks can all be used to create different layouts for monorails. Systems for monorails can be freestanding or installed on the ceiling.

Benefit of custom cranes

We can design whereas other manufacturer cannot

The most of crane manufacturers lack the design engineering skills required to evaluate your individual issues and offer a customized solution (such as maximizing lift height, accommodating constrained dimensions, or positioning loads in challenging work zones). So when you don't buy one of their conventional cranes, their salesmen tell you that it can't be done. These cranes typically barely fulfill your minimum criteria. And we can help with a unique crane design.

Your lifting requirements and application limits can be solved with our custom crane

Many customers contact us with a rudimentary idea of their handling system; they are aware of what they require and how it should function, but they lack the knowledge on how to construct it. Our plans offer the mechanical, electrical, and structural calculations necessary to turn their visions into final goods. Whether it's debugging a design or building and installing a unique crane system, we can do the same for you.

You want a system that is extremely effective, highly specialized, and focused on only one goal. Many of our clients employ cranes with specialized designs to carry out repetitive, high-duty-cycle activities throughout manufacturing. Call us if your manufacturing application calls for a crane to carry out a single task quickly, effectively, and with a high level of automation. Here is where our specially created cranes can benefit your company.

Special cranes for unique needs — customized lifting solutions

We at EOTCRANEKIT fully undetstand that lifting isn't a "one-size-fits-all" crane solutions. Many industries demand material handling cranes that are custom-made for unique production conditons and commercial requirements. As a result, we provide customized cranes and builtin cranes that are tailored to the specific needs of operators. Based on the various needs, the changes and modifications are needed to make the crane system fit the particular applicaitons and lifting requirements. More on our custom crane processed for particular loads handling

We can design a new overhead crane system or retrofit an used overhead crane.

After detailed consultation, our crane engineers will work with you to customize the overehad crane's type, capacity, speed, and lift to meet the precise requirements of your application. Reinforcements for increased capacities, lengthening or shortening of girder lengths, and adaptations for work in harsh temperatures are all possible modifications to existing crane system. More on Customized Crane Refurbishment.

Special cranes for unique needs — customized lifting solutions

It is a customized single girder overhead crane with telescopic cantilever design which are customized for the client's lifting conditons and requirements

Customized steel mill cranes for safe and efficient loads in steel plants

To address the harsh and challenging applicaitons conditions in steels mill plants, the customized overhead cranes are adopted to ensure safe and efficient handling of steel scrap, ladle billet plate, sheets, etc.

Custom build overhead crane sytmes for businesses needs

Our years of experience at EOTCRANKIT have allowed us to collaborate with businesses from virtually every industry. For lifting requirements of any size or type, we are professional fabricators of new overhead cranes and below-the-hook crane attachment. At EOTCRANKIT,our Hoist and Crane all are designed and tested to ensure safety.

We've built new overhead cranes of various types and sizes in our 34 years business operation. Our custom fabrications can be found in nuclear, aerospace, steel manufacturing, automotive, mining facilities, distribution centers, and many other industries' factories and warehouses.

We have provided numerous overhead crane solutions for multiple industrial sectors with full crane services to save you money, time, and energy as a hi-tech and innovation oriented crane manufacturer and supplier. To order your unique overhead traveling cranes, please contact us.

From metals production to general manufacturing, custom cranes are utilized in a variety of sectors, with each operation demanding something unique. Heat and dust protection is required for an overhead crane in a steel plant. Specialized grabs are required for power plants and waste-to-energy operations. Coil handling, stamping, and assembly are all handled by specific cranes at car manufacturing. Mining and basic metals processing sometimes take place in unique conditions, which usually needs crane adjustments, such as, explosion proof features, double braking to ensure safty, etc.

Features of custom cranes

Our custom cranes are usually have the following features:

How can custom cranes benefit you?

- The main benefits of the custom cranes are as following:

- A wide variety of lifting capacity allows for a wide range of applications.

- Proven technology that has been modified for the developped requirements and uses.

- Cutting-edge technology for improved performance and safety

- Superior engineering ensures optimal safety, dependability, and productivity.

- Full crane serives for clients worldwidely.

- Remote monitoring helps in the planning of operations to improve uptime productivity while minimizing downtime costs.

Custom fabricated below-the-hook devices

Our below-the-hook lifting devices for custom overhead cranes and custom gantry cranes can be custom fabricated to apply to the specific demands of your industry. We can modify regular "out-of-the-box" equipment into custom-built equipment that is optimized for maximum efficiency, whether it's little changes or entire refurbishments.

Any device you require can be designed and manufactured. Additionally, our custom crane CAD service and expert technicians may design a whole new overhead cane to match your specific needs.

Factor to consider when custom your crane

- The Load Weight. All electric overhead crane and hoist manufacturers require information about what you're lifting, including dimensions, total load weight, surface properties, shapes, material, construction, and fragility. Also, whether the load will be wet, dry, dusty, oily, or in another state as it is handled. It is also important to note if the electric overhead crane and hoist must handle more than one type of load. Depending on how different each load is from another, multiple overhead lifting and handling solutions may be recommended.

- The Frequency of Use. The frequency and percentage of the electric travelling crane and hoist's maximum load capacity will be used, also known as Duty Cycle Requirements, has a significant impact on the service class an application requires. Choosing hoisting equipment designed to meet the appropriate class for your application ensures its safety and longevity.

- The speed needed . The speed at which the travelling crane must travel and the hoist must lift and lower to keep up with manufacturing processes is critical to overall operational efficiency. An electric travelling overhead crane system that is either too fast or too slow can endanger operation safety and your workshop safety.

- The operational environment. Both interior and outdoor uses of cranes and hoists can provide unique challenges, such as temperature, hazardous circumstances, dust, heat, humidity, liquids, oils, fibers, corrosive chemicals, and more. To improve reliability and service life, a specially deigned custom crane and hoist combination may be suggested depending on the application.

- The anticipated lifespan. To ensure that electric overhead cranes and hoists function safely and effectively for the duration of their useful lives, routine maintenance is a requirement. A crucial factor to take into account when planning and customizing an overhead crane and hoist is how frequently an operation wants the equipment to run between servicing, to replace essential components, or to replace the complete system.

- The budget. Although it may be tempting to choose the overhead travelling crane and hoist solution with the lowest price, there is a good chance that system was not developed to fulfill the application's actual requirements. It is unlikely that a correctly constructed hoist and crane system will be the cheapest, but it will have a greater chance of lasting longer with fewer operational problems, less downtime, and a higher level of safety. Beyond the initial purchase price, all capital equipment expenditures have further costs. When adding up the hoist and crane price, be sure to take installation, spare parts, maintenance contracts, service agreements, and the desired level of field service team reaction to problems into consideration.

Contact Us to get your custom crane

Aside from the considerations outlined above, there are numerous buyer's guide resources available. These are designed to help overhead crane and gantry crane buyers in better evaluating their options and determining the best electric crane and hoist solution for their application.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch